Optical recording materials, optical recording materials solution, optical recording medium and method for manufacuturing same

An optical recording medium and optical recording technology, applied in temperature recording method, optical recording carrier, recording/reproducing by optical method, etc., can solve the problem of reduced productivity, difficulty in recycling optical recording material solution, short precipitation time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

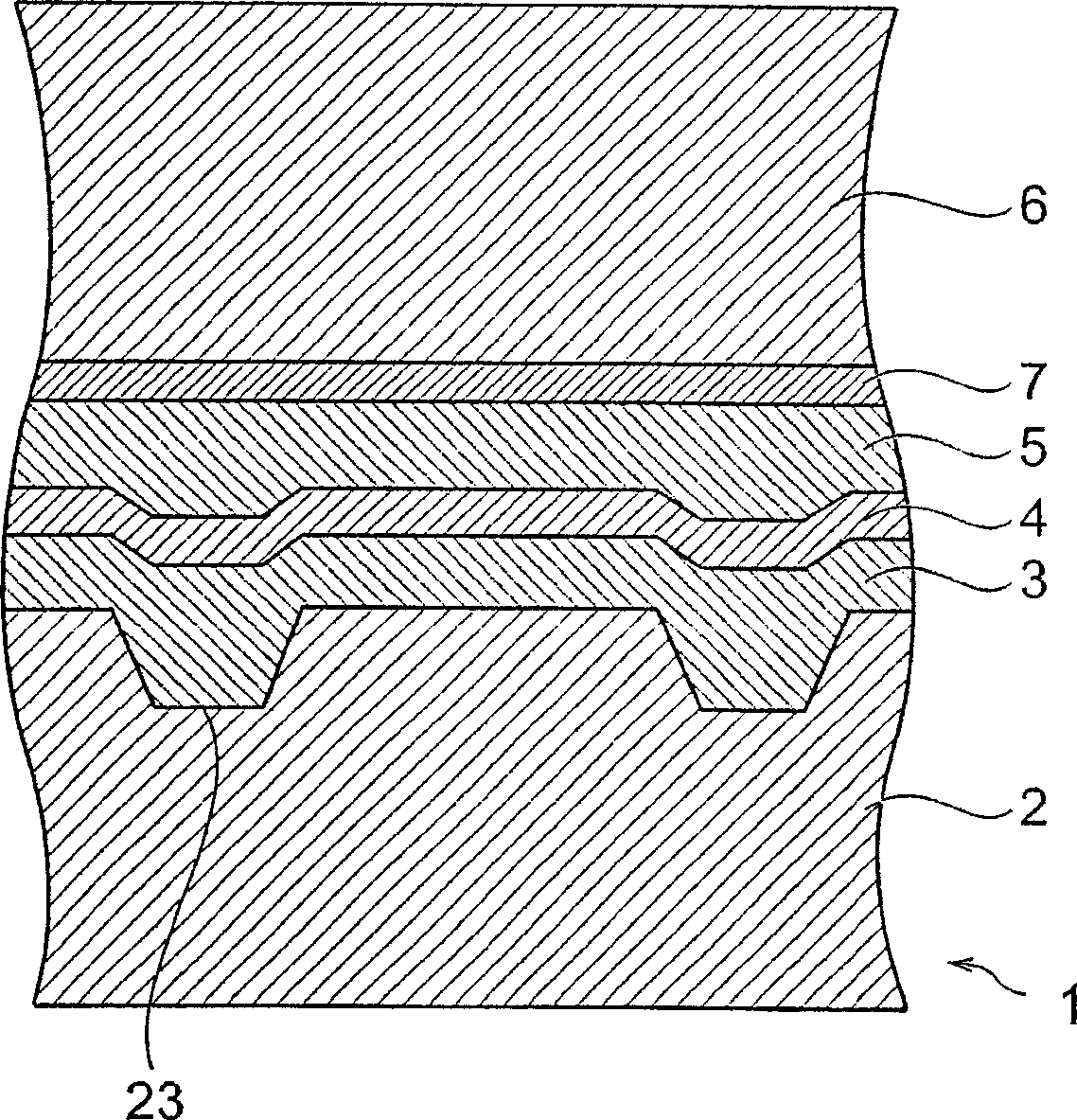

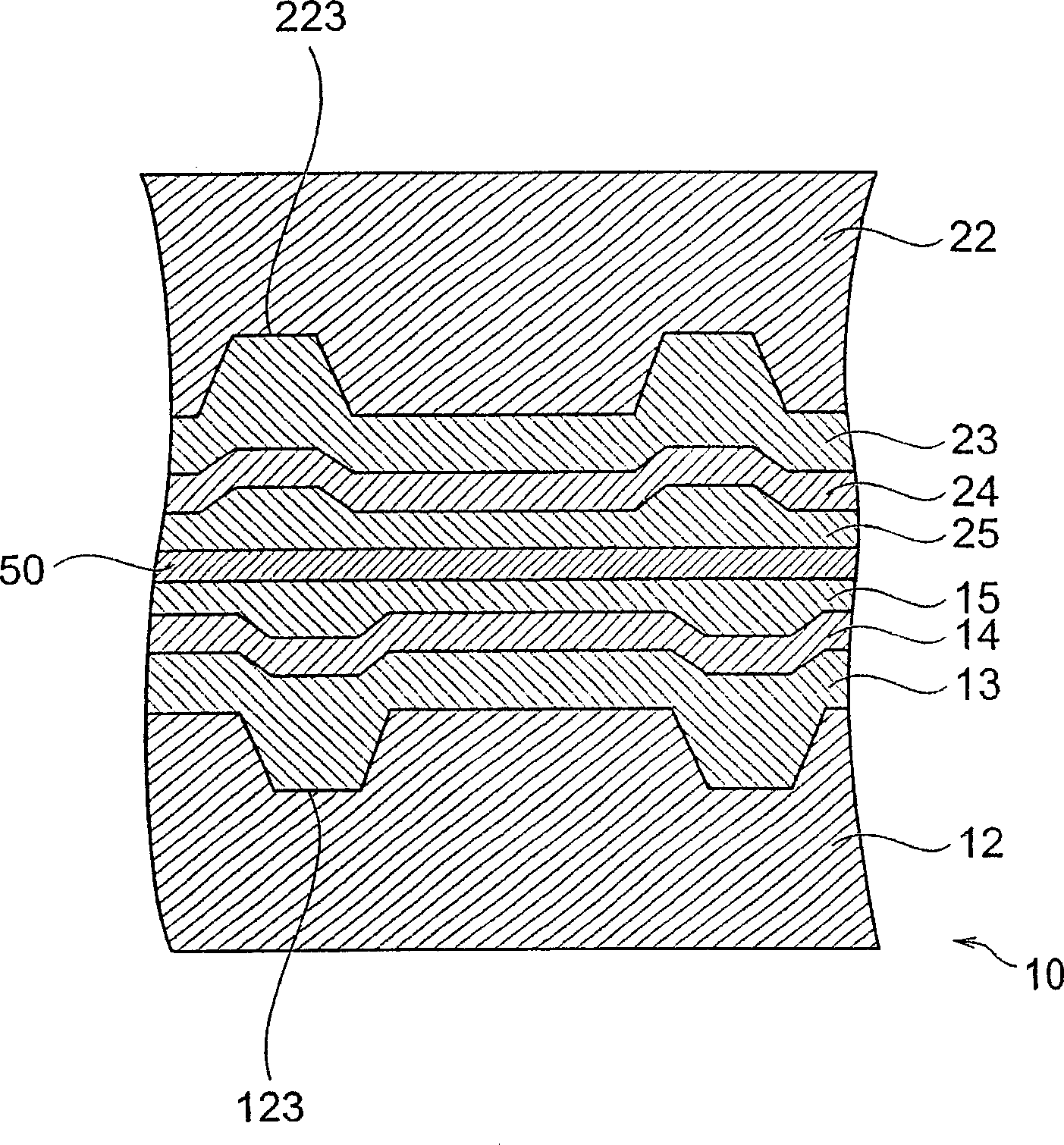

Image

Examples

Embodiment 1

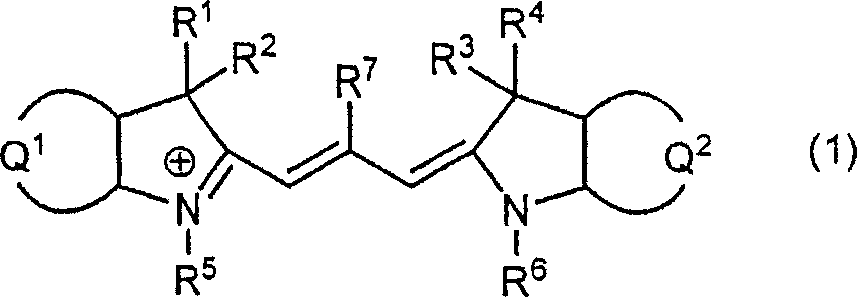

[0111] (Crystalization test)

[0112] The cyanine (A) made from the salt of cyanine cation (No.T21) and chelate (No.C3), and the cyanine cation (No.T21) and PF 6 - An optical recording material was prepared by mixing cyanine (B) made of a salt of 7:3 (molar ratio). The optical recording material and TFP as a solvent were filled in a 100 mL glass sample bottle so that the concentration of the optical recording material was 2% by mass. Then, ultrasonic treatment was performed for one hour while heating to 60° C. to obtain an optical recording material solution in which the optical recording material was dissolved.

[0113] The obtained optical recording material solution was filtered through a 0.2 μm membrane filter, and then stored in a glass sample bottle at a room temperature of 25° C., and the precipitation state of crystals was observed every day. One drop of the optical recording material solution taken out of the sample bottle was poured onto the polycarbonate substrat...

Embodiment 2~20

[0119] The optical recording material is the combination of each pigment shown in Table 13 and the material of the mixing ratio. Depending on the situation, OFP is used as a solvent. Others are the same as in Example 1, and the crystallization test, the production of the optical recording disc, and its evaluation. As a result, the days to crystallization exceeded 30 days for all optical recording materials, and the jitter values well met the specifications before and after light irradiation. In addition, in any case, the yield of optical recording disks was above 98%. Wherein, in Table 13, the numbers of cyanine pigment cations and chelate compounds correspond to No. shown in Tables 1 to 7 and Table 12, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com