Generation of solid laser with biquadratic harmonic wave

A solid-state laser, fourth harmonic technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of easy deliquescence of CLBO, soft and brittle materials, etc., achieve high conversion efficiency, avoid sudden changes, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

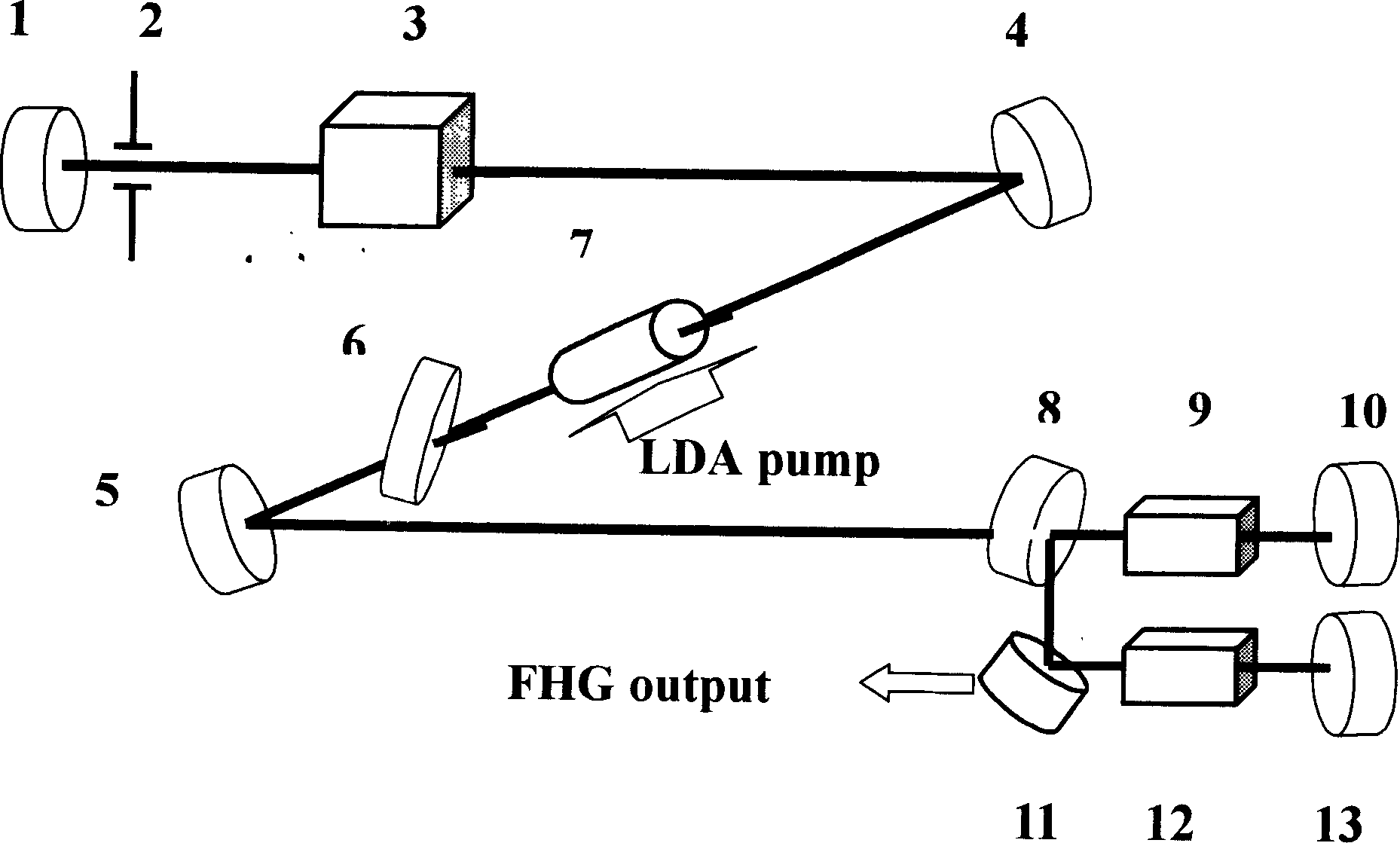

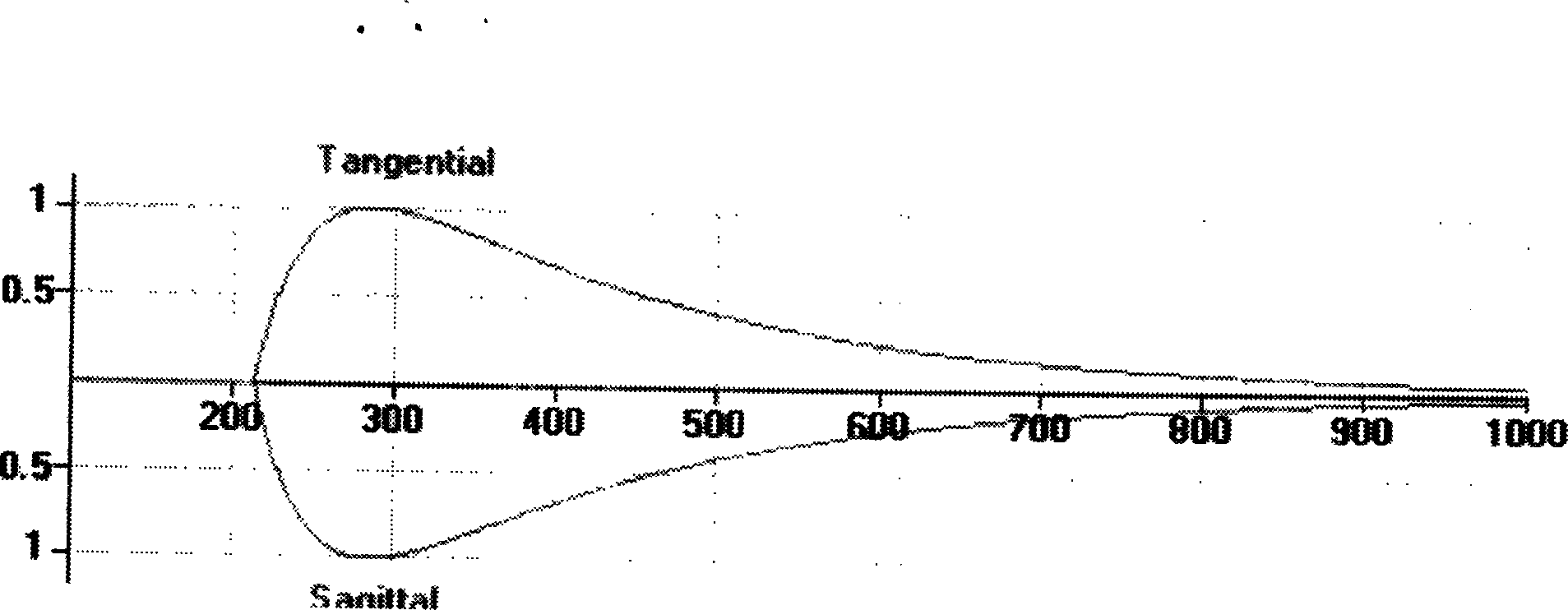

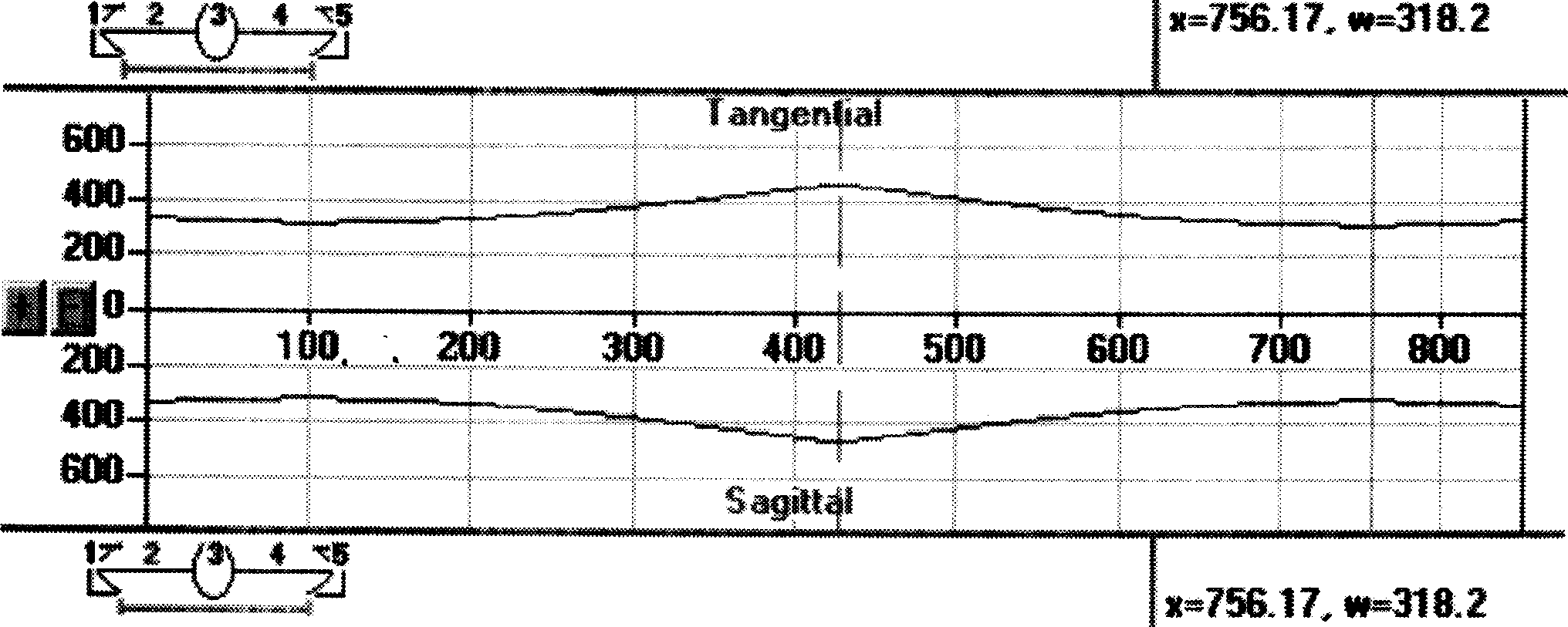

[0024] The principle of the fourth harmonic solid-state laser generation method of the present invention is as follows: figure 1 As shown, a fundamental wave oscillator is adopted, which includes a high-power laser diode array side pump module 7, a Q switch 3, a vertical linear polarizer 6, a mode-limiting aperture 2, and a terminal total reflection mirror (1, 10, 13), nonlinear crystals (9, 12) and angular mirrors (4, 5, 8, 11). Wherein the angle mirrors (4, 5, 8, 11) are intracavity small-angle mirrors. By calculating and measuring the thermal lens effect of the pump module 7 under different pump powers, and using the optical matrix method to calculate the spatial distribution of the Gaussian mode transmission in the cavity, the cavity length and the curvature of the end mirror are designed to make the infrared laser cavity thermally The lens still maintains a stable oscillation under a wide range of changes, and the calculation results are as follows Figure 2a and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com