Adhesive method for metal piece and plastic piece and adhered machine casing thereof

A technology for metal parts and plastic parts, which is applied in the field of bonding methods and the chassis into which they are bonded, can solve problems such as insufficient glue dispensing and overflowing glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

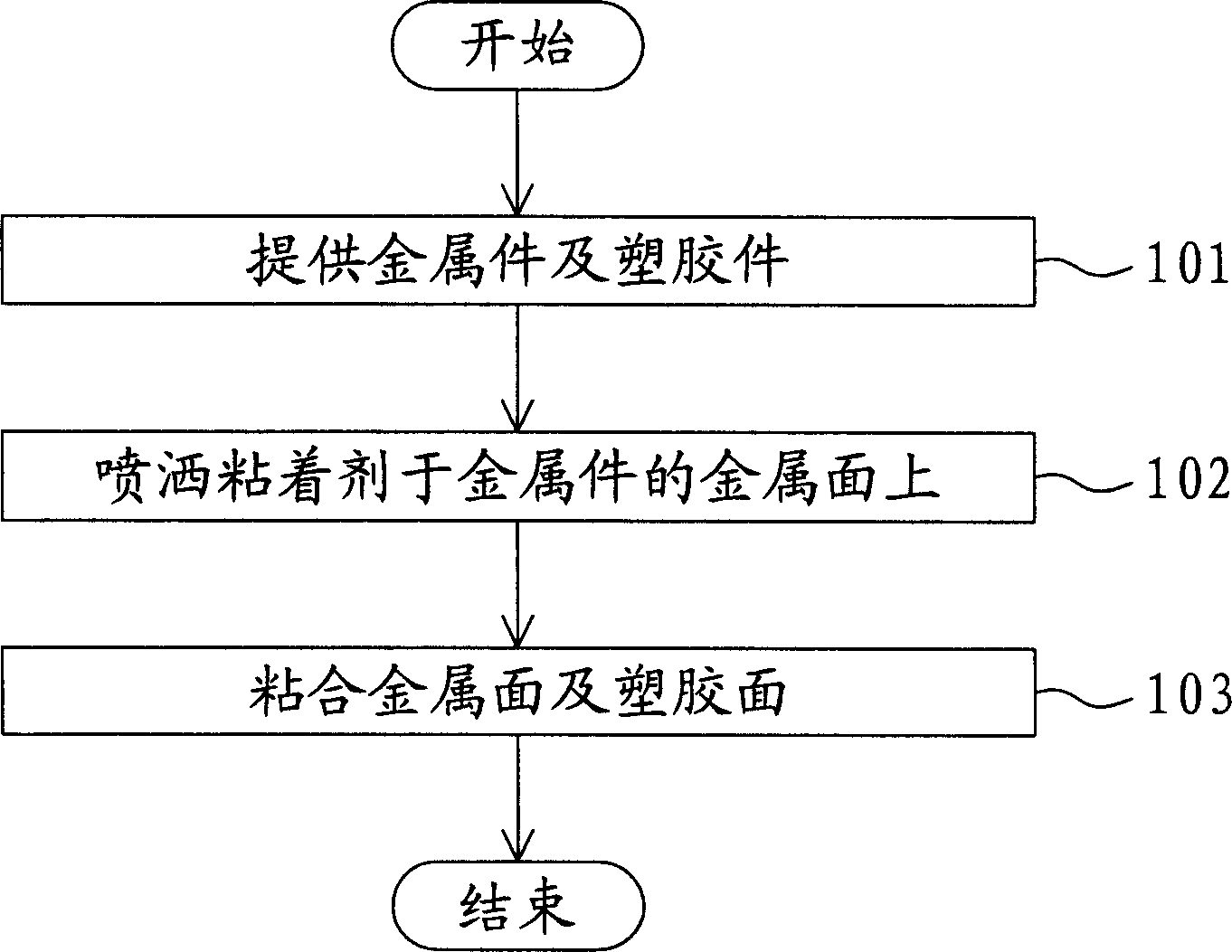

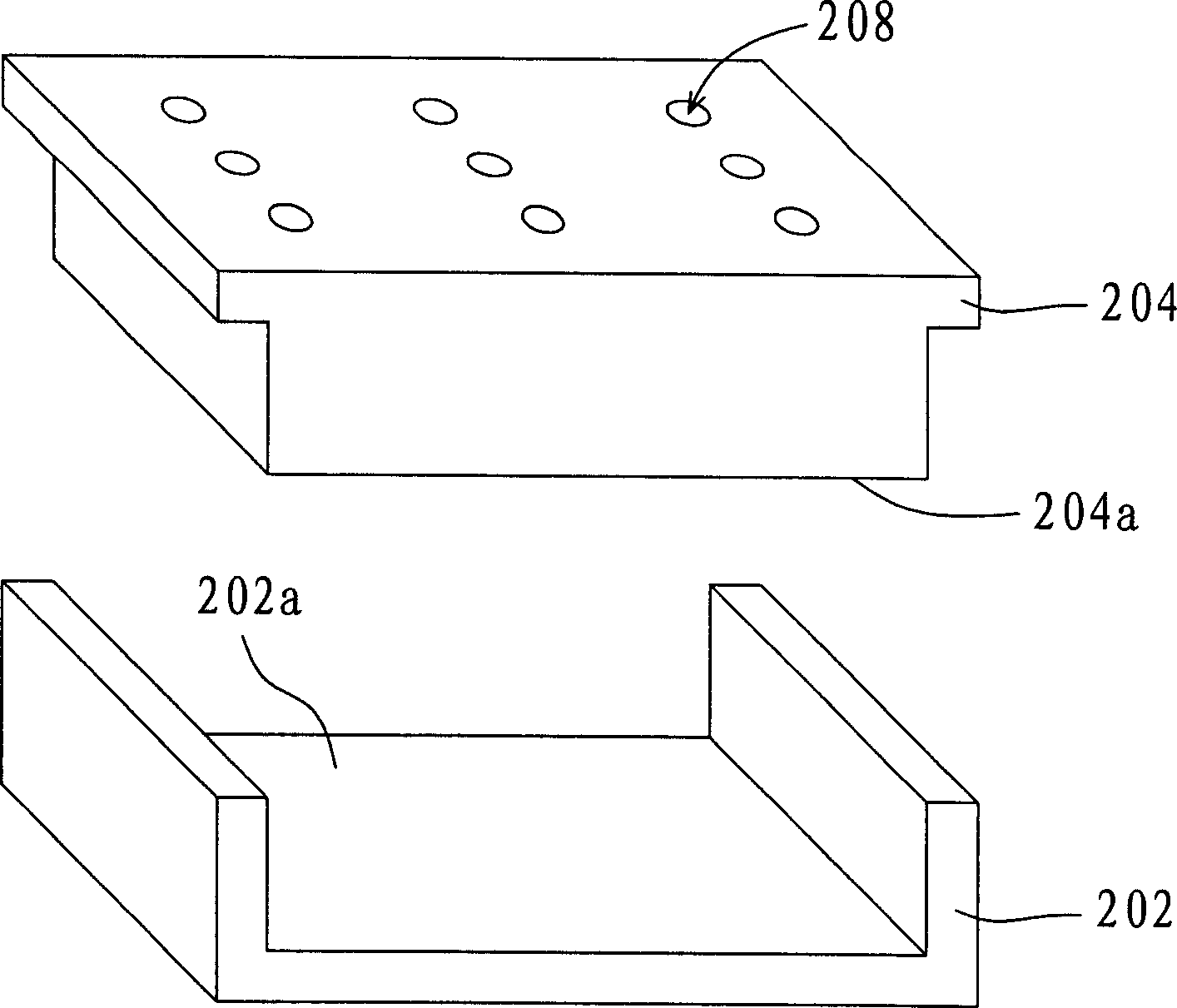

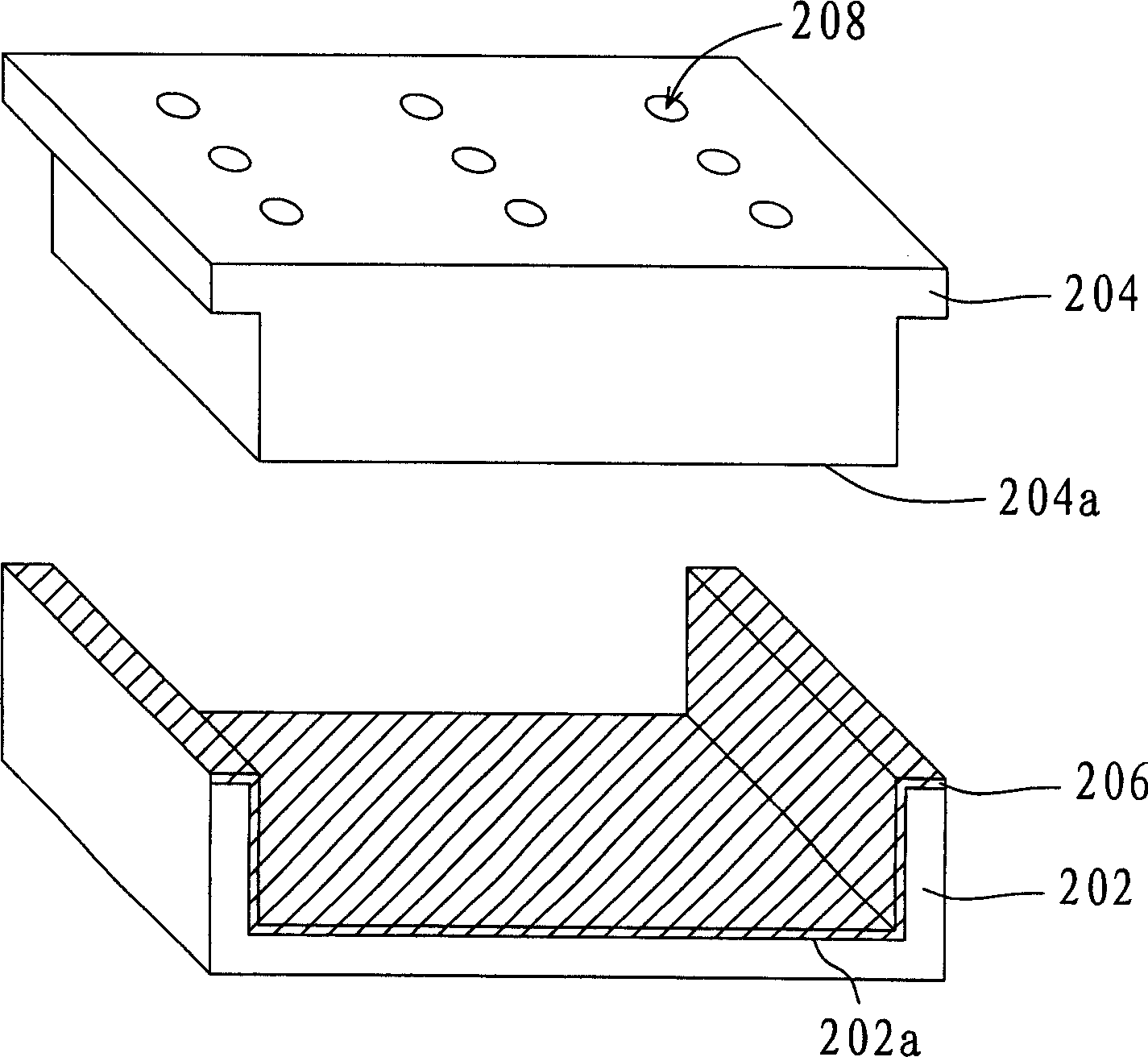

[0016] The bonding method of metal parts and plastic parts of the present invention includes the following steps. First, provide metal parts and plastic parts. The metal piece has a metal surface. The plastic part has a plastic surface corresponding to the metal surface. Next, spray the adhesive on the metal surface so that the adhesive can be more evenly distributed on the metal surface. Finally, glue the metal surface and the plastic surface.

[0017] The main concept of the present invention is to spray the adhesive on the metal surface of the metal parts to evenly spread the adhesive on the metal parts; It can effectively get rid of the fetters of the traditional design of bonding metal parts and plastic parts with point-like distribution or strip-like distribution of adhesives. In this way, it can avoid the problem of insufficient or overflowing glue when traditionally using a dispenser to distribute the adhesive in dots or strips on the metal surface or plastic surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com