Glass frosting liquid with AG (anti-glare) effect as well as preparation and application of glass frosting liquid

A frosting liquid and glass technology, applied in the field of etching glass, can solve the problems of iterative products without characteristics, short life cycle, single effect, etc., and achieve more ornamental, good anti-drop performance, and good touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

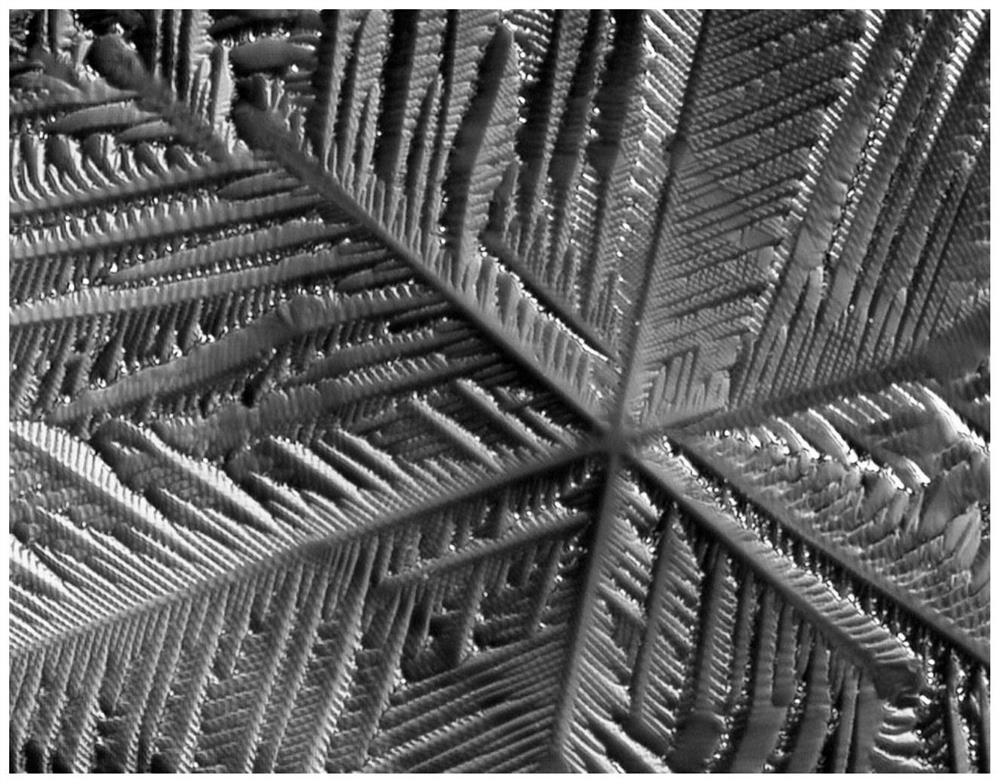

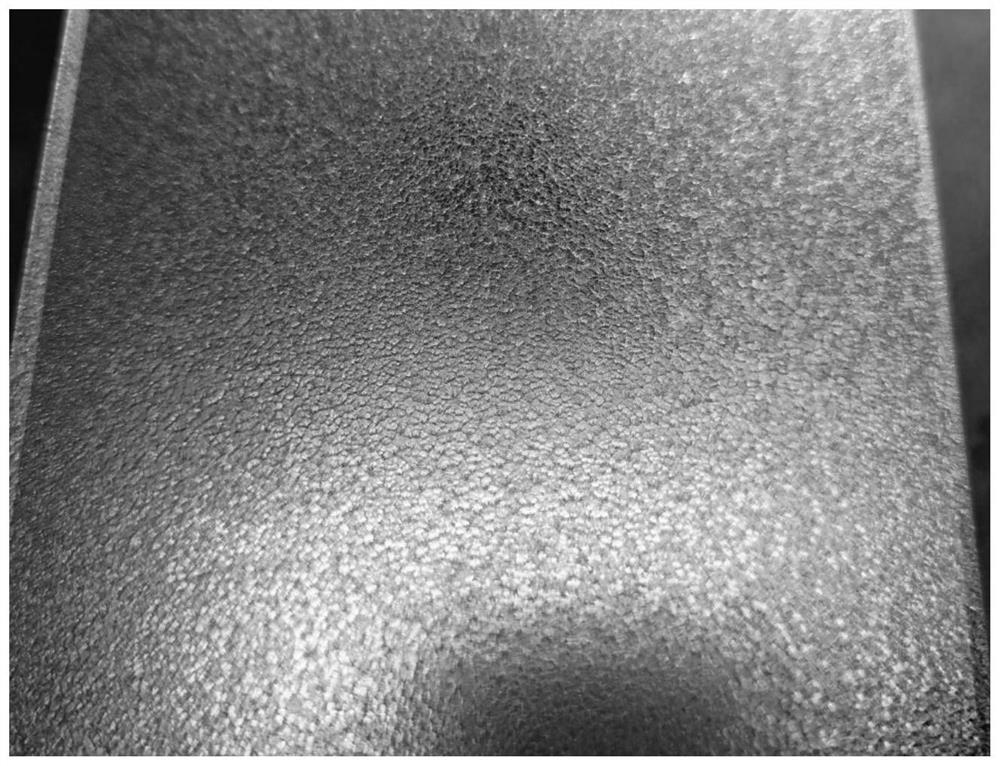

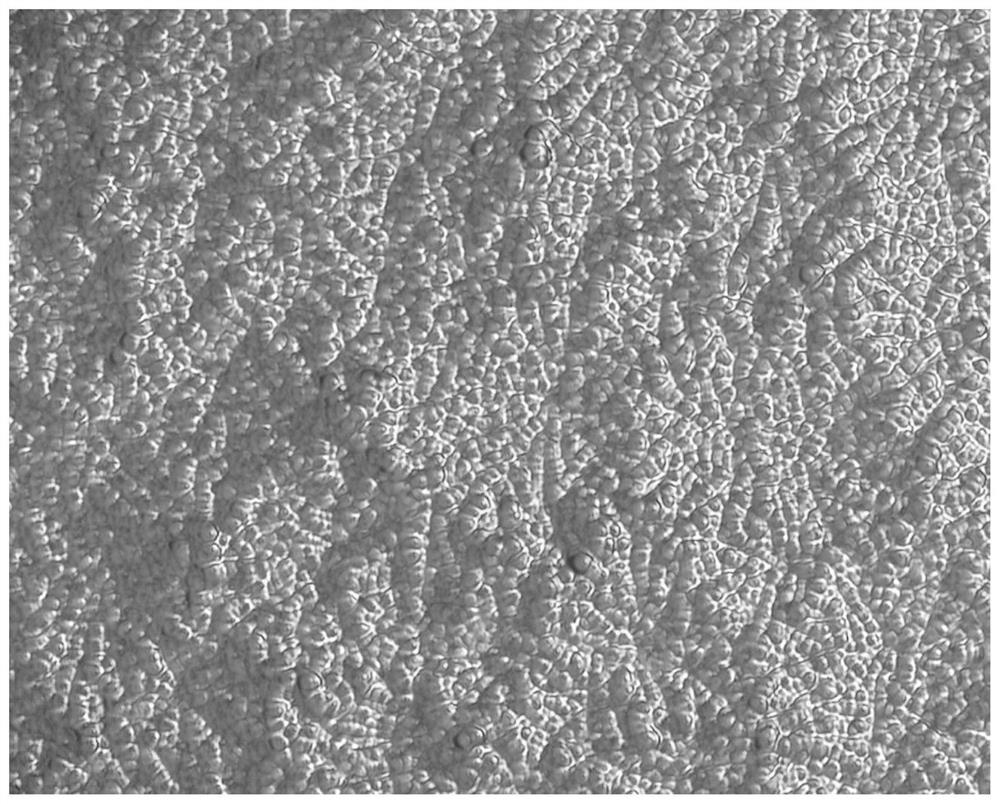

Image

Examples

Embodiment approach

[0037] In one embodiment, a novel glass frosting liquid with AG effect includes the following components by weight percentage: 25-30% fluoride, 25-30% acid, 12-16% inorganic salt, and water balance.

[0038] In some preferred embodiments, the content of the fluoride is 25-30 wt%. In one embodiment, the content of the fluoride is 25wt%; in another embodiment, the content of the fluoride is 30wt%; in another embodiment, the content of the fluoride is 28wt%.

[0039] In some preferred embodiments, the fluoride includes at least one of ammonium bifluoride and ammonium fluoride. In one embodiment, the fluoride is ammonium bifluoride; in another embodiment, the fluoride is ammonium fluoride; in yet another embodiment, the fluoride is ammonium bifluoride and ammonium fluoride.

[0040] In some preferred embodiments, the content of the acid is 25-30 wt%. In one embodiment, the content of the acid is 25 wt %; in another embodiment, the content of the acid is 30 wt %; in another embod...

Embodiment 1

[0046] A new glass frosting liquid with AG effect, including the following components by weight: 25% ammonium bifluoride, 18% concentrated hydrochloric acid, 12% concentrated sulfuric acid, 4% tricalcium phosphate, 3% sodium citrate, 5% Potassium sulfate, water balance.

[0047] The above components are mixed in proportion, and the solution is repeatedly stirred to obtain a supersaturated solution, which can be used after being matured in a water bath at 50°C for 72 hours.

[0048] Glass etching:

[0049](1) The side of the original glass sheet that does not need to be etched is protected by screen printing with anti-etching ink;

[0050] (2) Clean the side of the original glass sheet that needs to be etched with a pretreatment solution, put it into a frosting equipment in a wet state, and the frosting equipment is equipped with the above-mentioned frosting liquid of the present invention, and the temperature is controlled to soak at 15-20 ° C 180s, swing while soaking;

[...

Embodiment 2

[0053] A new glass frosting liquid with AG effect, including the following components by weight: 19% ammonium bifluoride, 11% ammonium fluoride, 15% concentrated hydrochloric acid, 15% concentrated sulfuric acid, 4% tricalcium phosphate, 6% Sodium citrate, balance of water.

[0054] The above components are mixed in proportion, and the solution is repeatedly stirred to obtain a supersaturated solution, which can be used after being matured in a water bath at 50°C for 72 hours.

[0055] Glass etching:

[0056] (1) The side of the original glass sheet that does not need to be etched is protected by screen printing with anti-etching ink;

[0057] (2) Clean the side of the original glass sheet that needs to be etched with a pretreatment solution, put it into a frosting equipment in a wet state, and the frosting equipment is equipped with the above-mentioned frosting liquid of the present invention, and the temperature is controlled to soak at 15-20 ° C 180s, swing while soaking;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com