Dedusting and carding device capable of achieving in-line arrangement of mop strips

A cloth strip and main frame technology, which is applied in the cutting of textile materials, cleaning methods using liquids, textiles and papermaking, etc., can solve the problems of time-consuming, messy, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

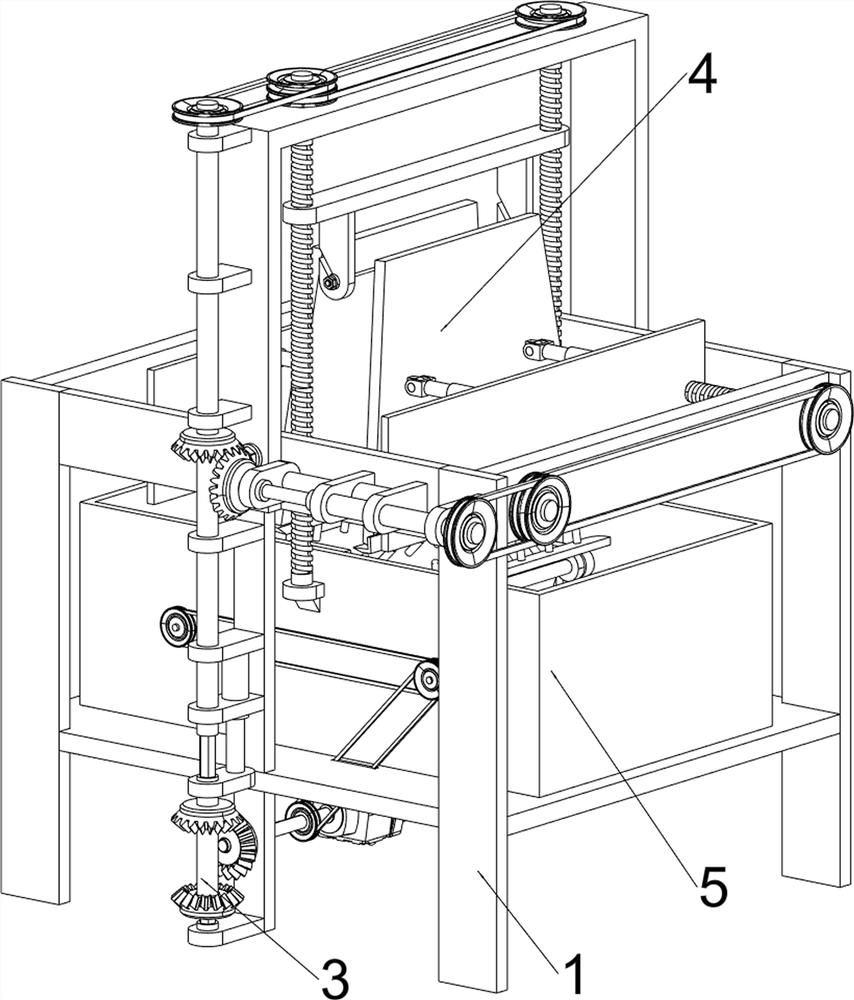

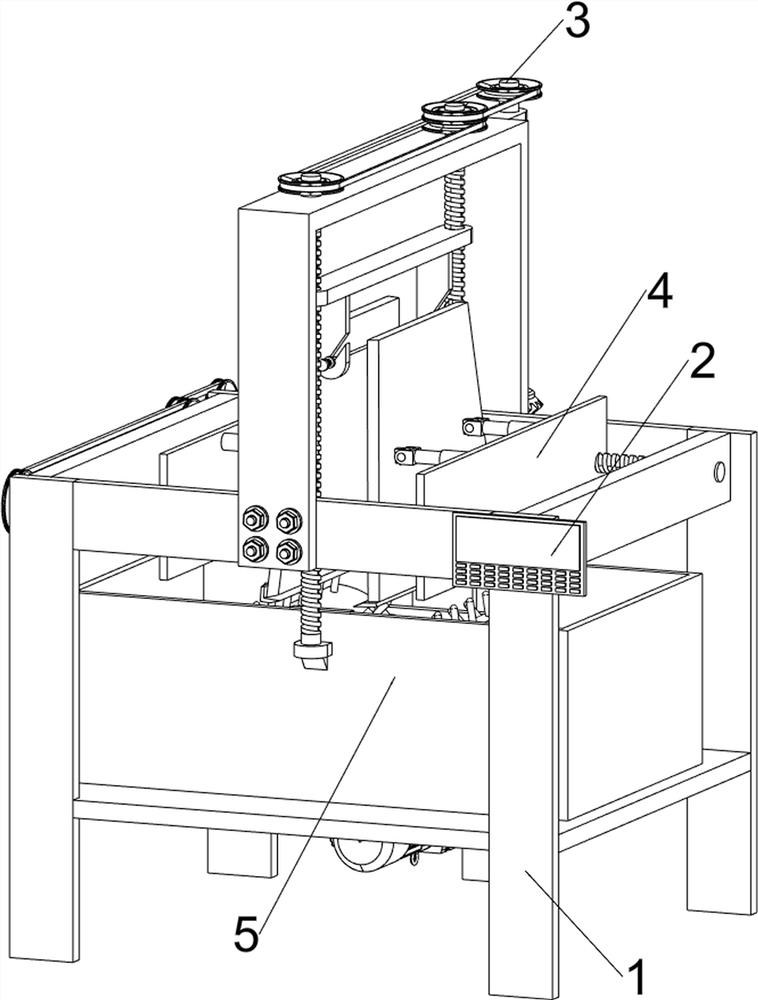

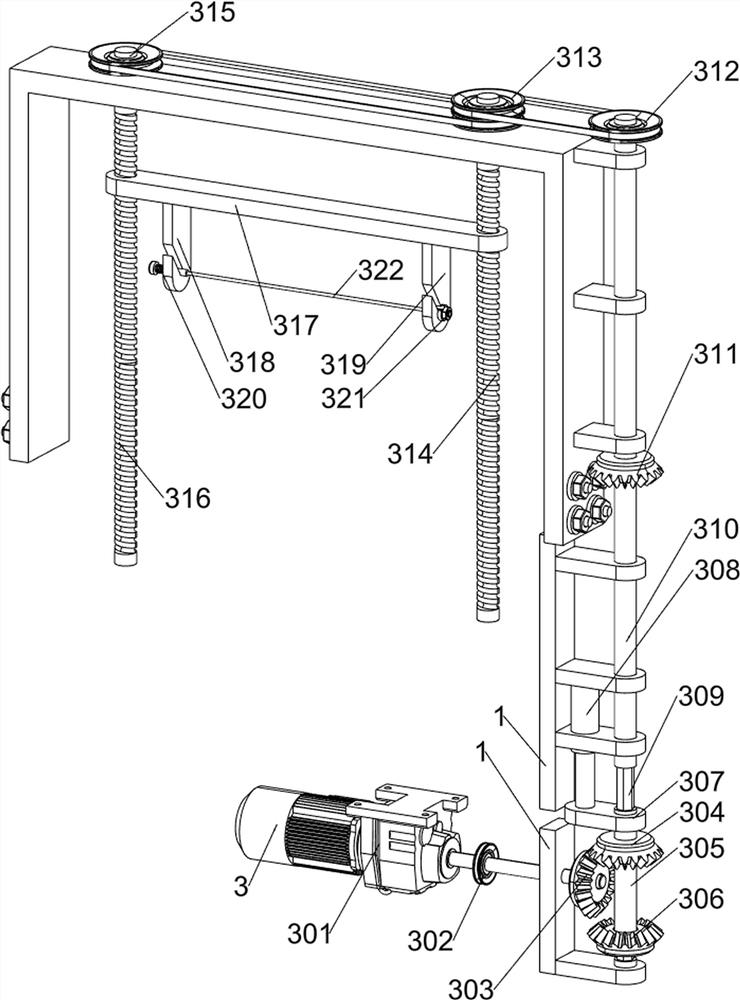

[0030] A kind of dedusting carding device that can line up mop strips, such as Figure 1-10 As shown, it includes a main frame 1, a control panel 2, a transmission system 3, an extrusion cutting system 4 and a smoothing system 5; the main frame 1 is used for supporting devices; the control panel 2 is connected with the main frame 1; The main frame 1 is connected; the extrusion cutting system 4 is connected with the main frame 1, the extrusion cutting system 4 is connected with the transmission system 3; the smoothing system 5 is connected with the main frame 1, and the smoothing system 5 is connected with the transmission system 3 connect.

[0031] Working principle: When using this device, first install the device horizontally at the place where it needs to be used, connect the external power supply, control the operation of the device by manually opening the control panel 2, add the mop strips prepared in advance to the transmission system 3, and pass the transmission system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com