Backward flowing preventing device for air blowoff duct

A technology for air exhaust and anti-backflow, which is applied to vertical pipes, building components, buildings, etc., and can solve the problems of insufficient suction effect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

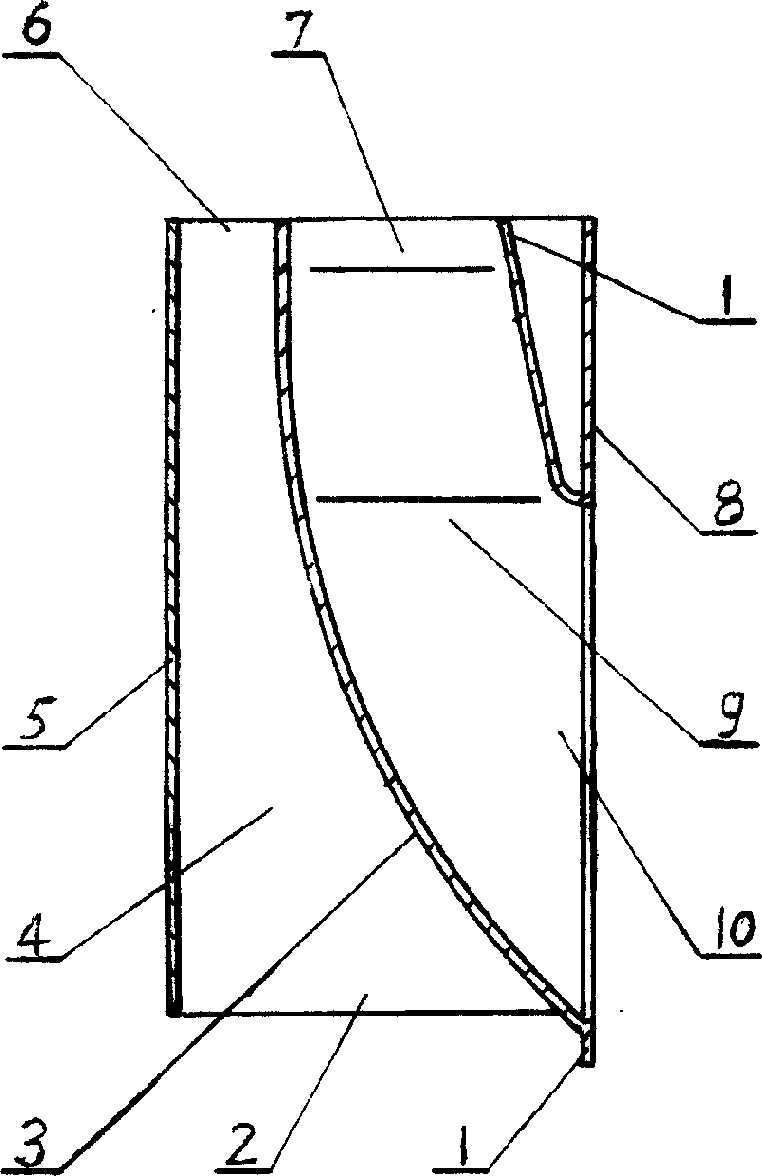

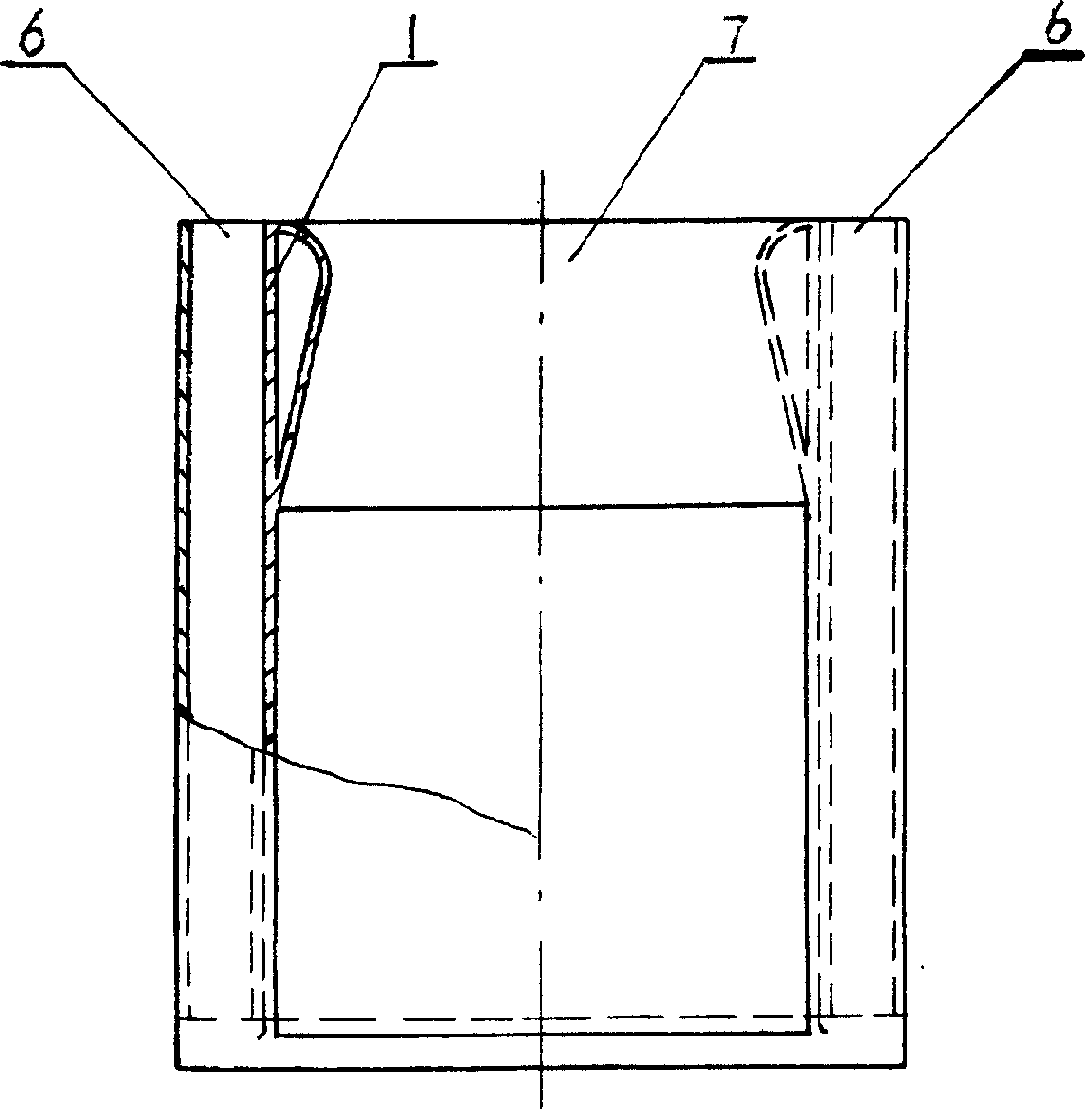

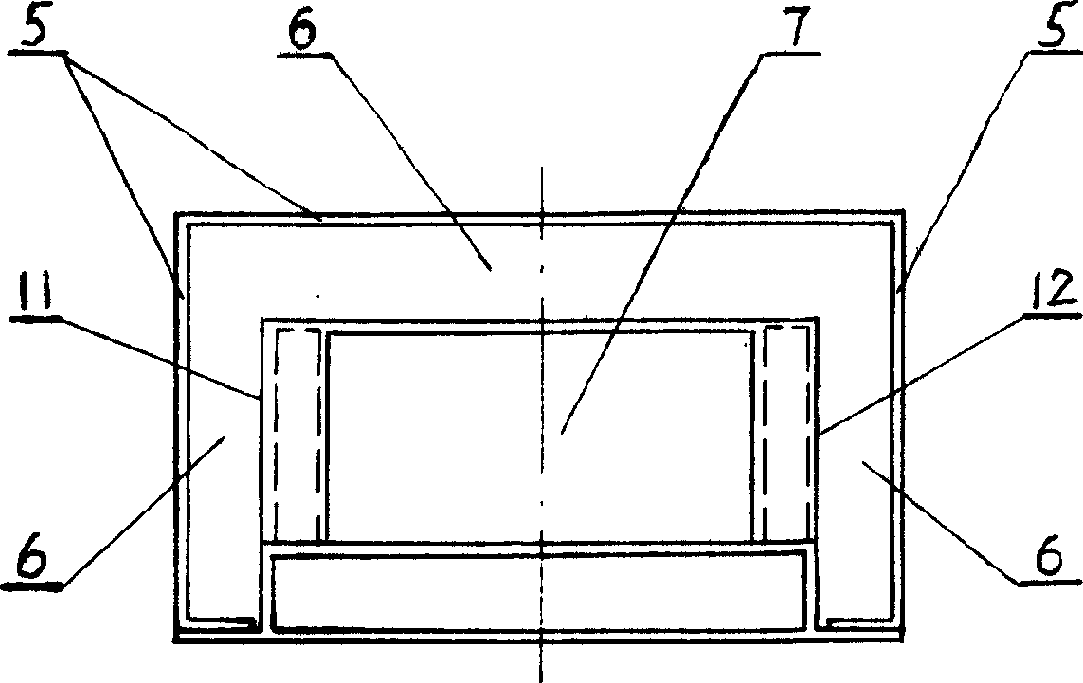

[0010] Such as Figure 1-3 As shown, the present invention includes a housing 1 and a speed change plate 5 arranged outside the housing 1. The outer shape of the housing 1 is a cone with a thin bottom and a thick top. The housing 1 includes an air inlet side 8 and a speed change side 3 and The left side 11 and the right side 12 are provided with an air induction channel 9 in the housing 1, the air inlet 10 of the air induction channel is arranged on the air inlet side 8, and the air outlet 7 is on the top surface of the housing. The cross-section of the air outlet 7 facing upwards gradually decreases, and the cross-section at the air outlet is the smallest, and the whole air-inducing channel is just like a pot mouth. The speed change plate 5 is arranged around the outside of the speed change side 3, the left side 11, and the right side 12, and a lower air inlet 2 is formed between the speed change plate 5 and the speed change side 3, the left side 11, and the right side 12. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com