Flue gas backflow preventing chimney for zinc oxide smelting

A zinc oxide, anti-backflow technology, applied in the field of chimneys, can solve the problems of single structure and poor anti-backflow effect, and achieve the effects of reducing air pollution, purifying flue gas, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

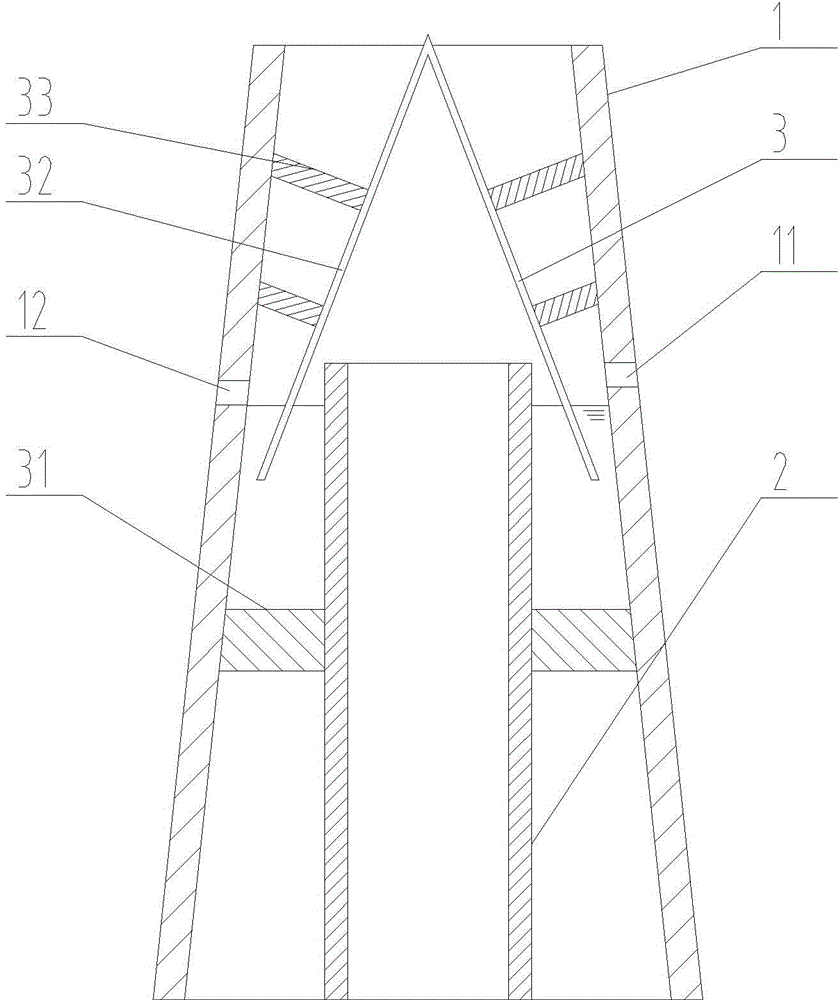

[0011] The present invention as figure 1 As shown, it includes a body 1, an air intake pipe 2 and an anti-backflow assembly 3, the body 1 is empty of the air intake pipe 2, and the top edge of the air intake pipe 2 is located in the middle of the body 1;

[0012] The anti-backflow assembly 3 includes an annular bottom plate 31, an umbrella-like baffle 32 and several support rods 33, the inner edge of the bottom plate 31 is fixedly connected to the outer wall of the intake pipe 2, and its outer edge is fixedly connected to the body On the inner wall of 1, the baffle 32 is fixedly connected in the body 1 through several support rods 33, and is located above the intake pipe 2, and the bottom edge of the baffle 32 extends between the intake pipe 2 and the body 1, so The body 1 is also provided with a water inlet 11 and an overflow port 12, the water inlet 11 is higher than the top opening of the air intake pipe 2, the overflow port 12 is higher than the bottom edge of the baffle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com