Oil box cover for large-scale bus

A technology for fuel tank caps and passenger cars, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power devices, etc., can solve problems such as insufficient sealing and anti-leakage performance, and achieve increased anti-theft, outstanding effects, and increased safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

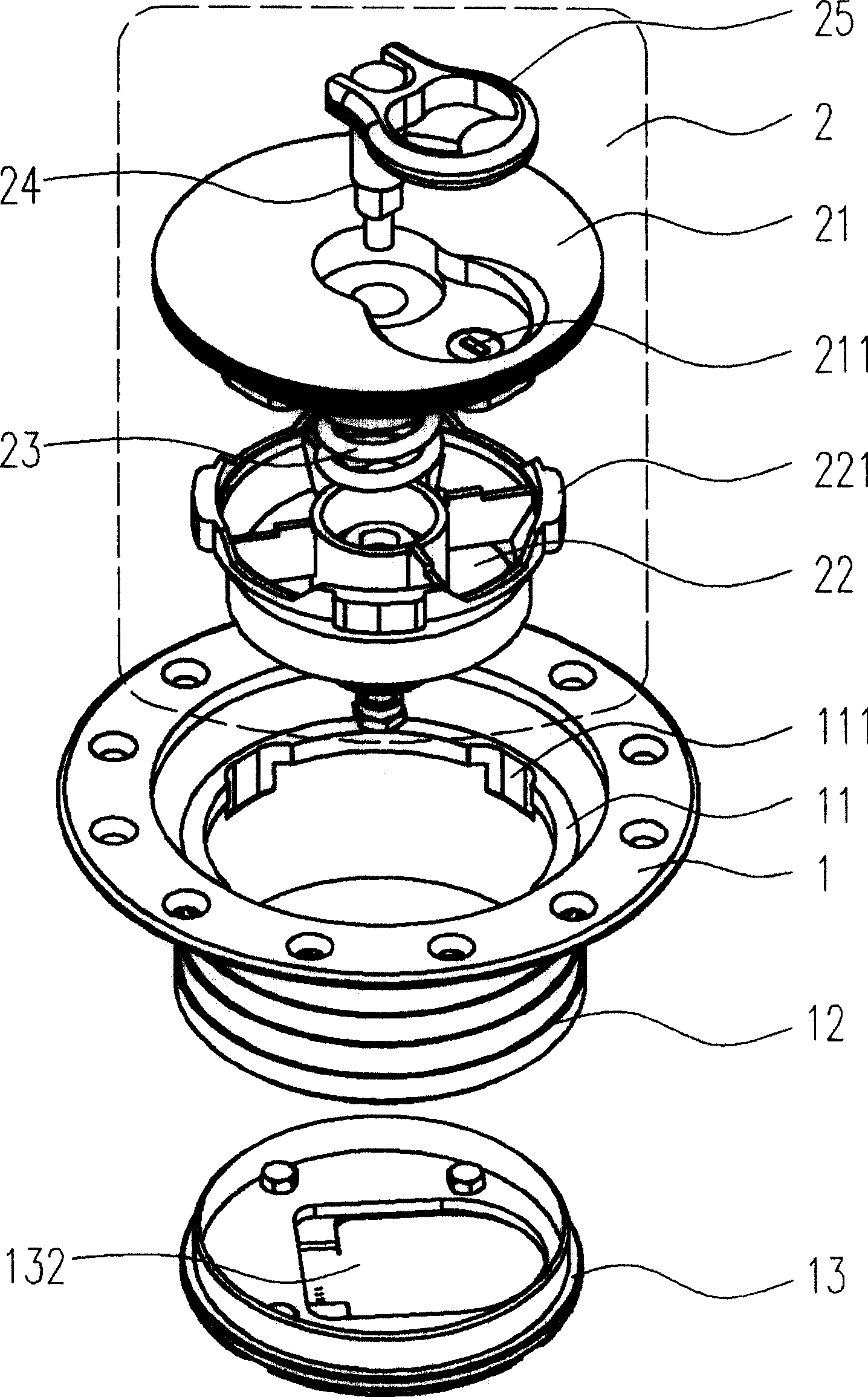

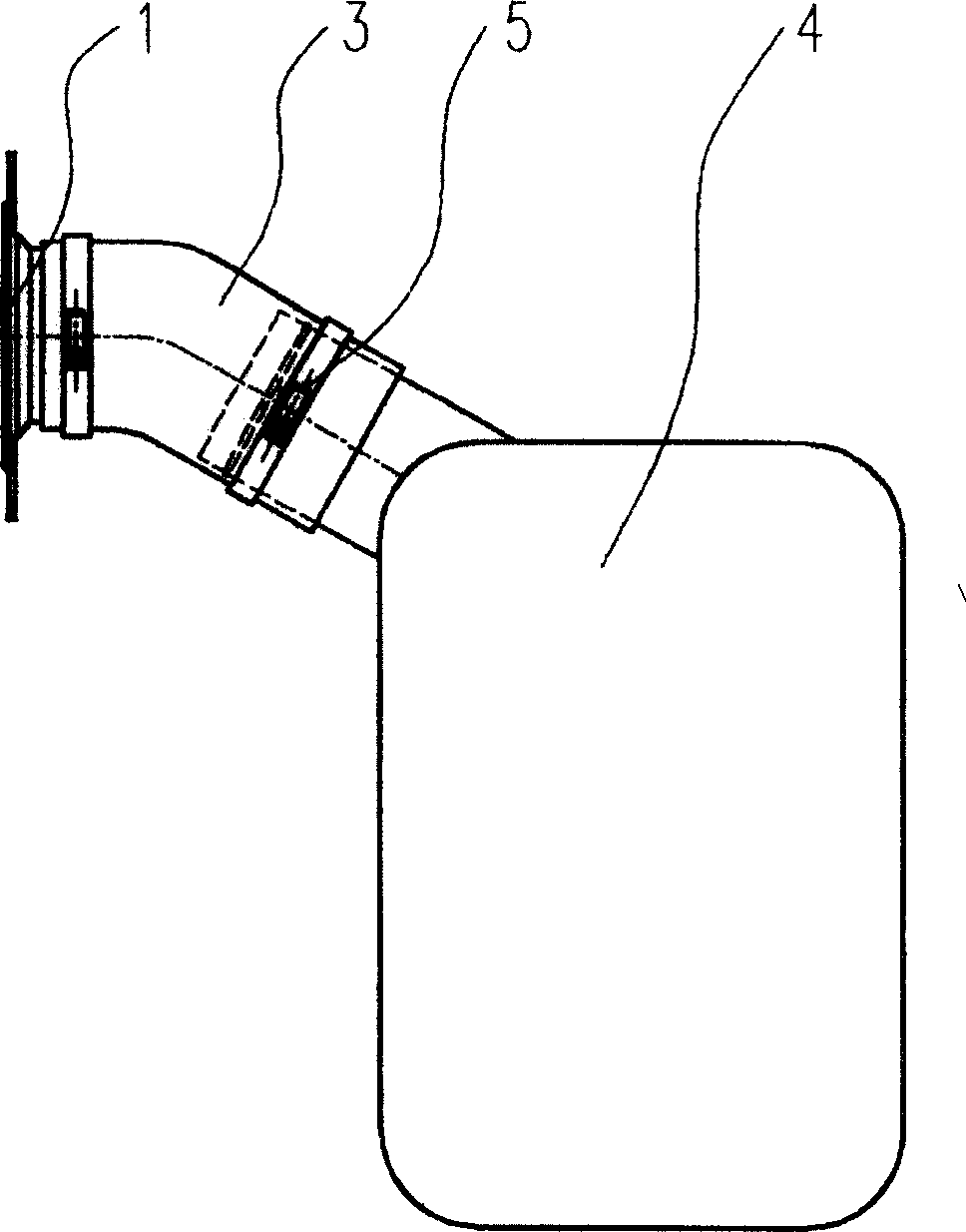

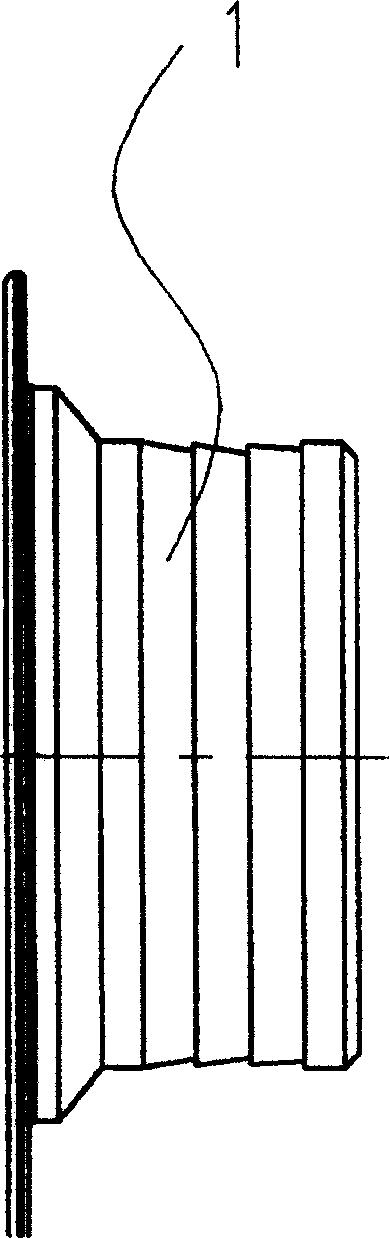

[0025] Such as figure 1 , figure 2 , Figure 5 Shown, a kind of fuel tank cap that is used on the large passenger car comprises a connection seat 1, a sealing cap 2; The connection seat 1 is positioned on the shell of the automobile shell, and a refueling through hole is arranged on the connection seat 1, and the refueling A pipe sleeve 12 extends out of the through hole in the axial direction, and the pipe sleeve is connected with the fuel tank 4 inside the vehicle through an oil-resistant pipe 3, and is fastened and sealed by the tightening hoops 5 at both ends. The opening of the pipe sleeve 12 is equipped with an anti-backflow plate 13, such as Figure 8 As shown, the anti-backflow plate 13 includes a torsion spring 131 and a cover plate 132. One end of the torsion spring 131 is fixed on the anti-backflow plate 13, and the other end is fixed on the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com