Vehicle floor structure

A floor and vehicle technology, applied in the direction of superstructure, vehicle parts, superstructure sub-assembly, etc., can solve the problems of increasing material and labor costs, reducing mechanical strength, complicating the manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

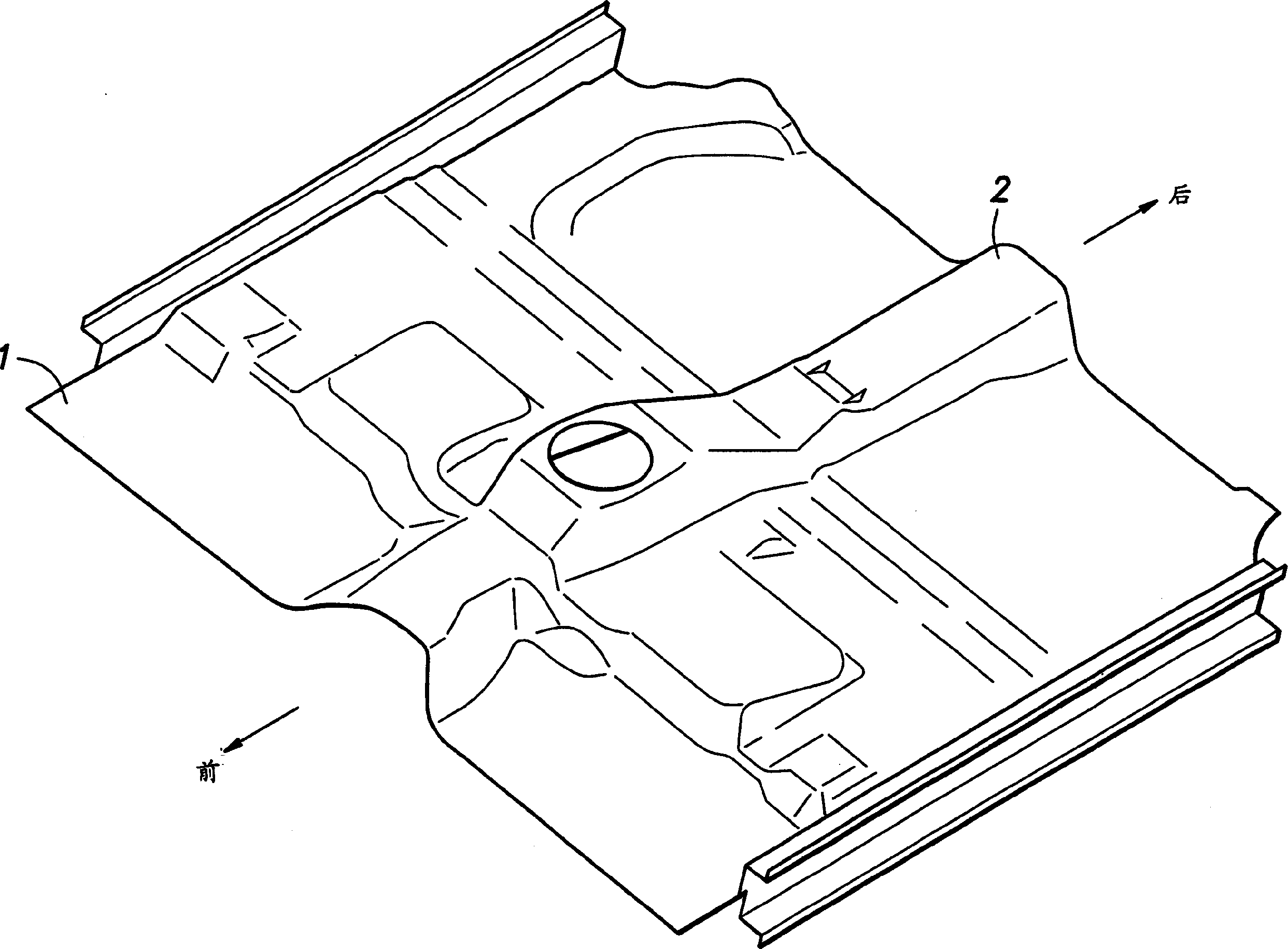

[0021] figure 1 is a partial perspective view of a vehicle floor panel 1 embodying the invention. As shown in the figure, the floor panel 1 is stamped and formed from a thinner steel plate, and has several raised beadings (not shown in the figure), which are used to accommodate various components connected to the floor panel 1 and increase the floor surface. Bending stiffness of panel 1.

[0022] Such as figure 1 As shown, the transverse center portion of the floor panel is formed by a floor tunnel 2 extending in the front-to-rear direction and having a trapezoidal cross-section to ensure the bending rigidity of the vehicle body around the transverse line.

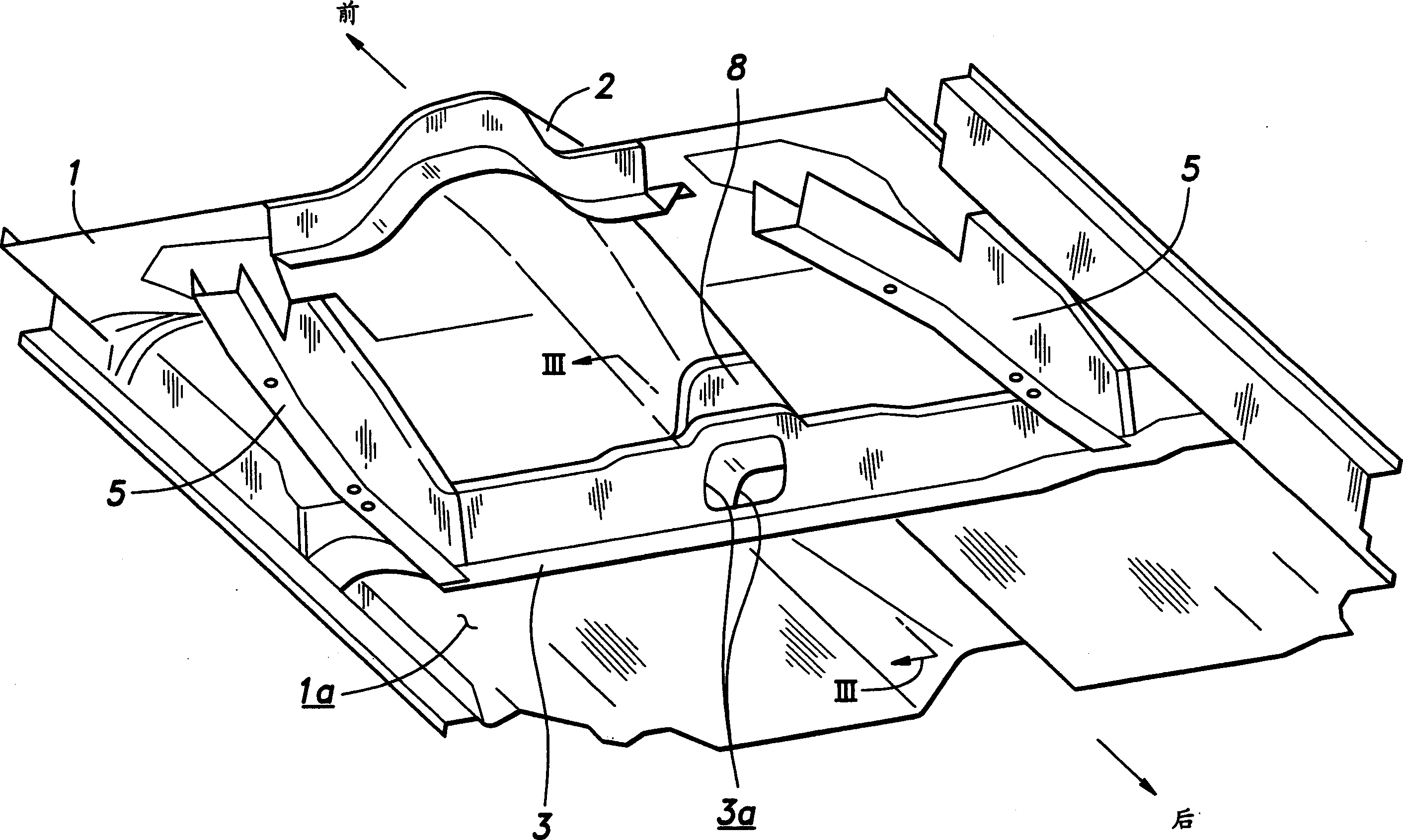

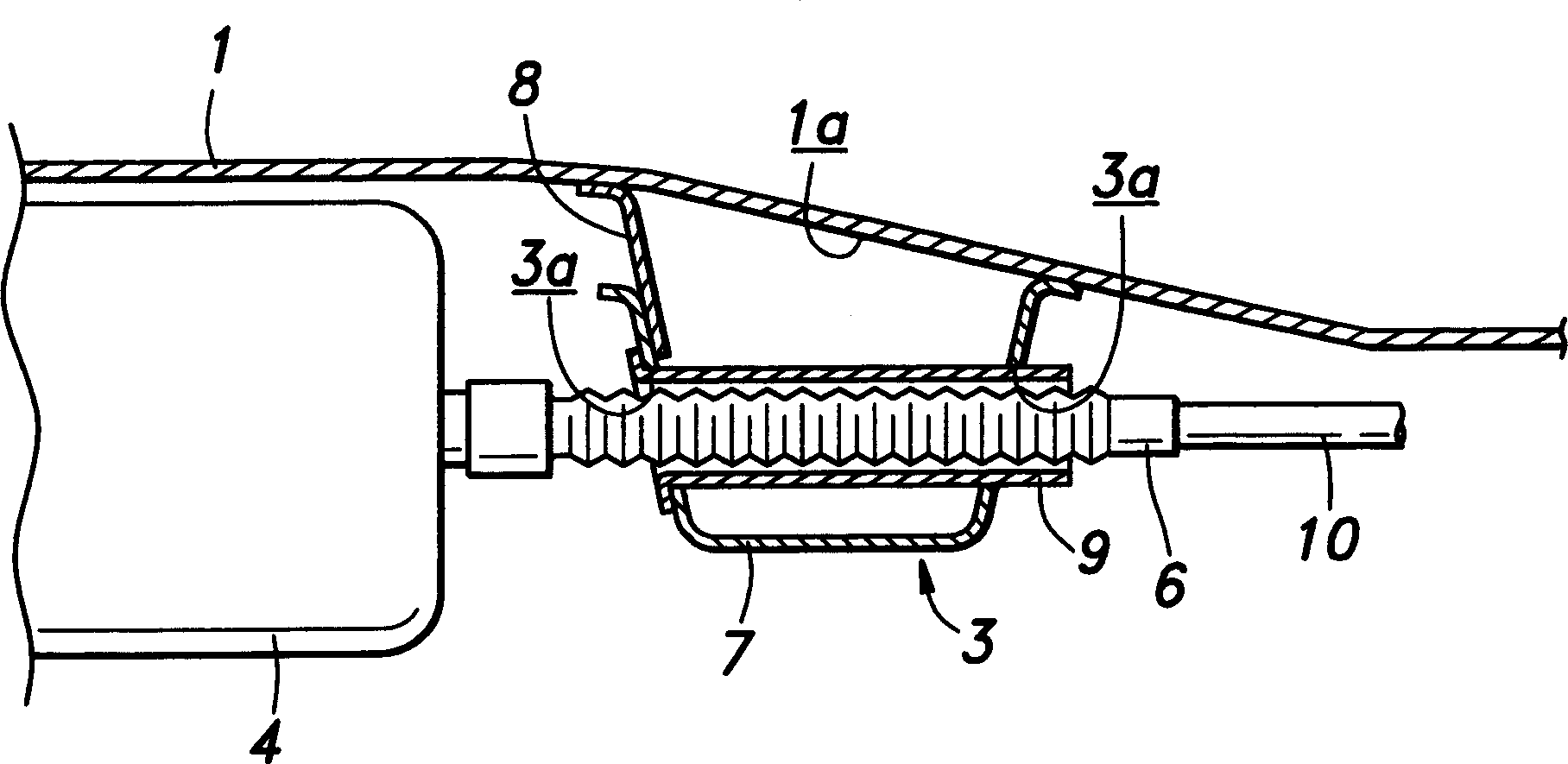

[0023] It is also required that the floor panel 1 ensures sufficient bending stiffness of the body around the longitudinal line. To meet this requirement, the lower surface 1a of the floor panel 1 is connected to a cross member 3 which extends transversely through the vehicle body and forms a figure 2 The illustrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com