Piezoelectric motor

A technology of piezoelectric motors and piezoelectric sheets, applied in the field of motors, can solve problems such as difficult control of the boundary conditions of piezoelectric motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

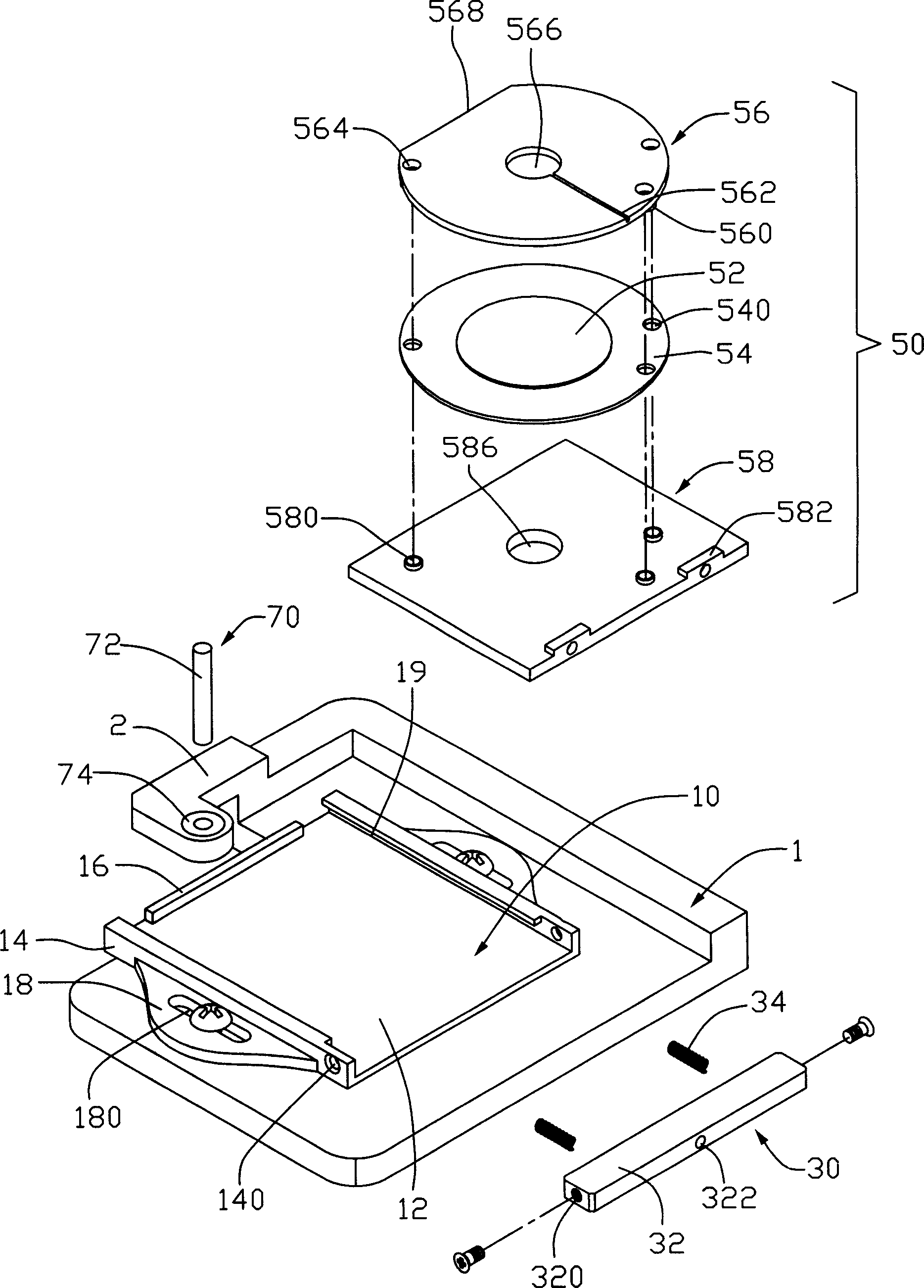

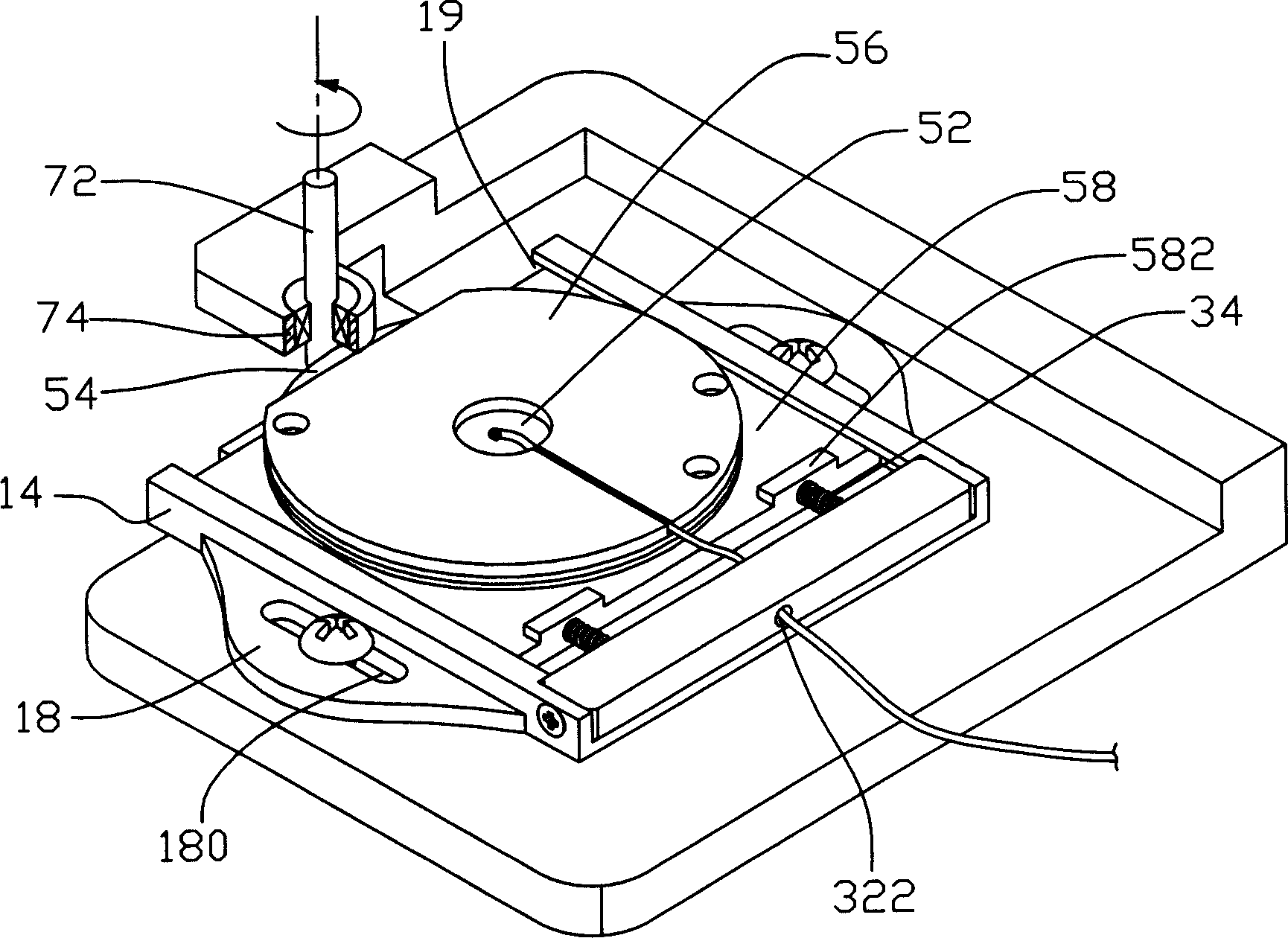

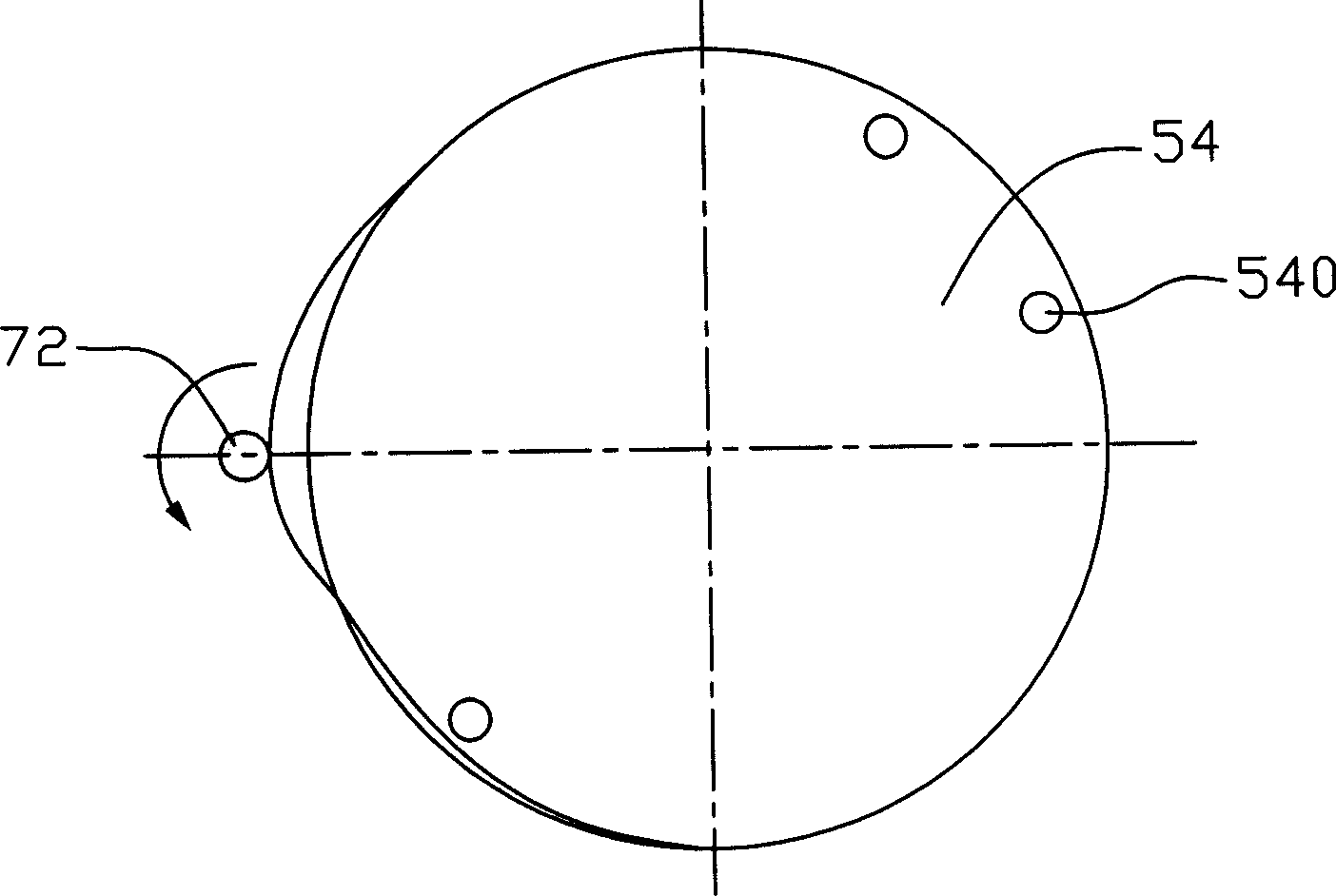

[0012] Such as figure 1 and figure 2 As shown, the piezoelectric motor includes a base 10, a drive module 50 arranged on the base 10, a pre-compression mechanism 30 connected between the base 10 and the drive module 50 and a contact with the drive module 50. rotor 70.

[0013] The base 10 is fixed on a fixed seat 1, and the base 10 includes a substantially square bottom plate 12, a stopper 16 is formed on the side of the bottom plate 12 close to the rotor 70, and the two sides adjacent to the bottom plate 12 and the stopper 16 are respectively A side wall 14 is formed, and both the stopper 16 and the side wall 14 extend upward perpendicular to the bottom plate 12 . Wherein the bottom plate 12 forms a flange 18 outwards on both sides where the side wall 14 is located, and a fixing groove 180 is formed on each flange 18. Fasteners such as screws pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com