Annular binding member

A binding and ring technology, applied in binding, folder, printing and other directions, can solve the problems of large width and size of base parts, difficulty in ensuring quality stability, and difficulty in design and production, and achieve simple structure and structural strength. And the effect of improving quality stability and realizing design and manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention will be described below with reference to the drawings.

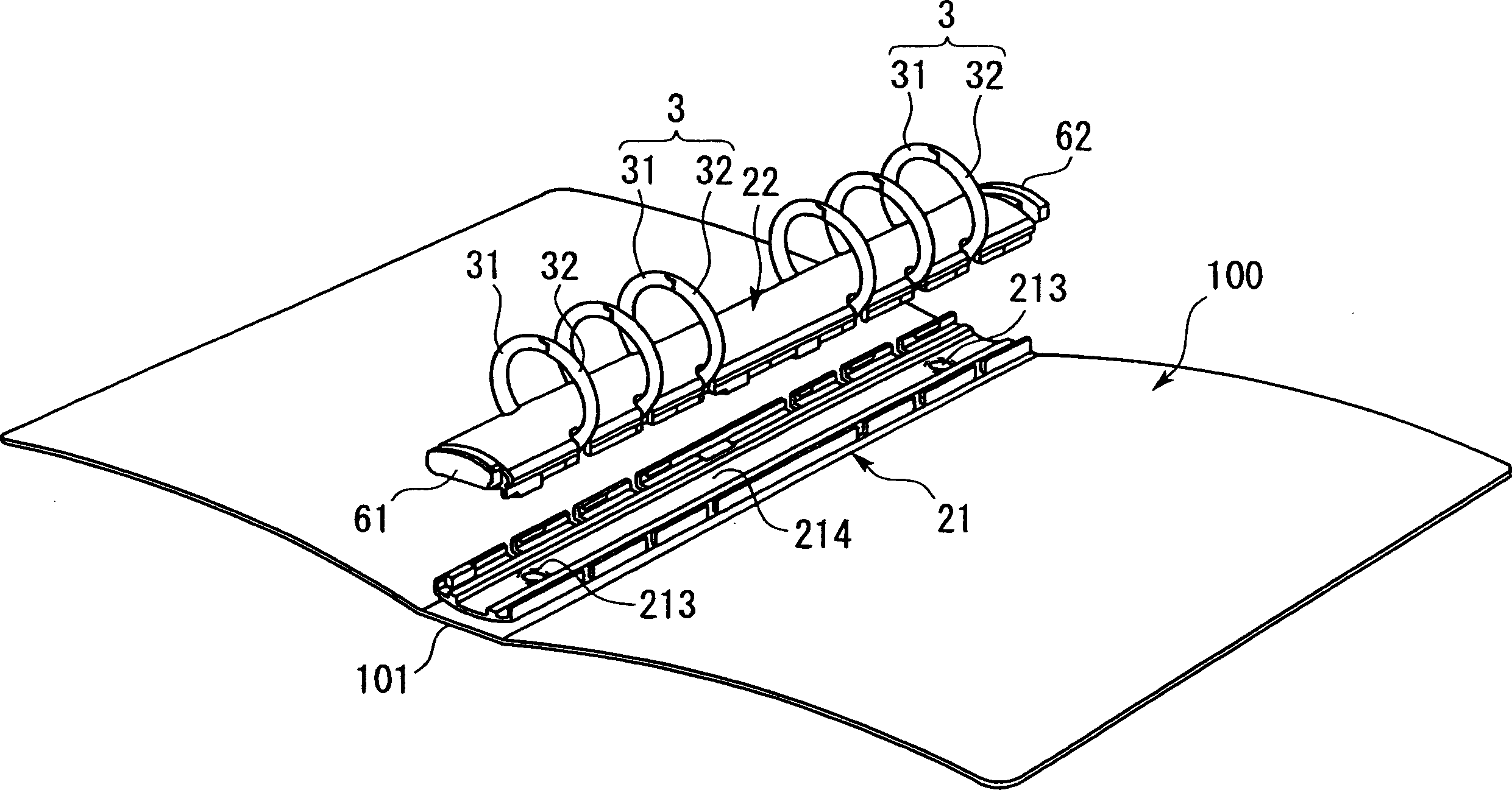

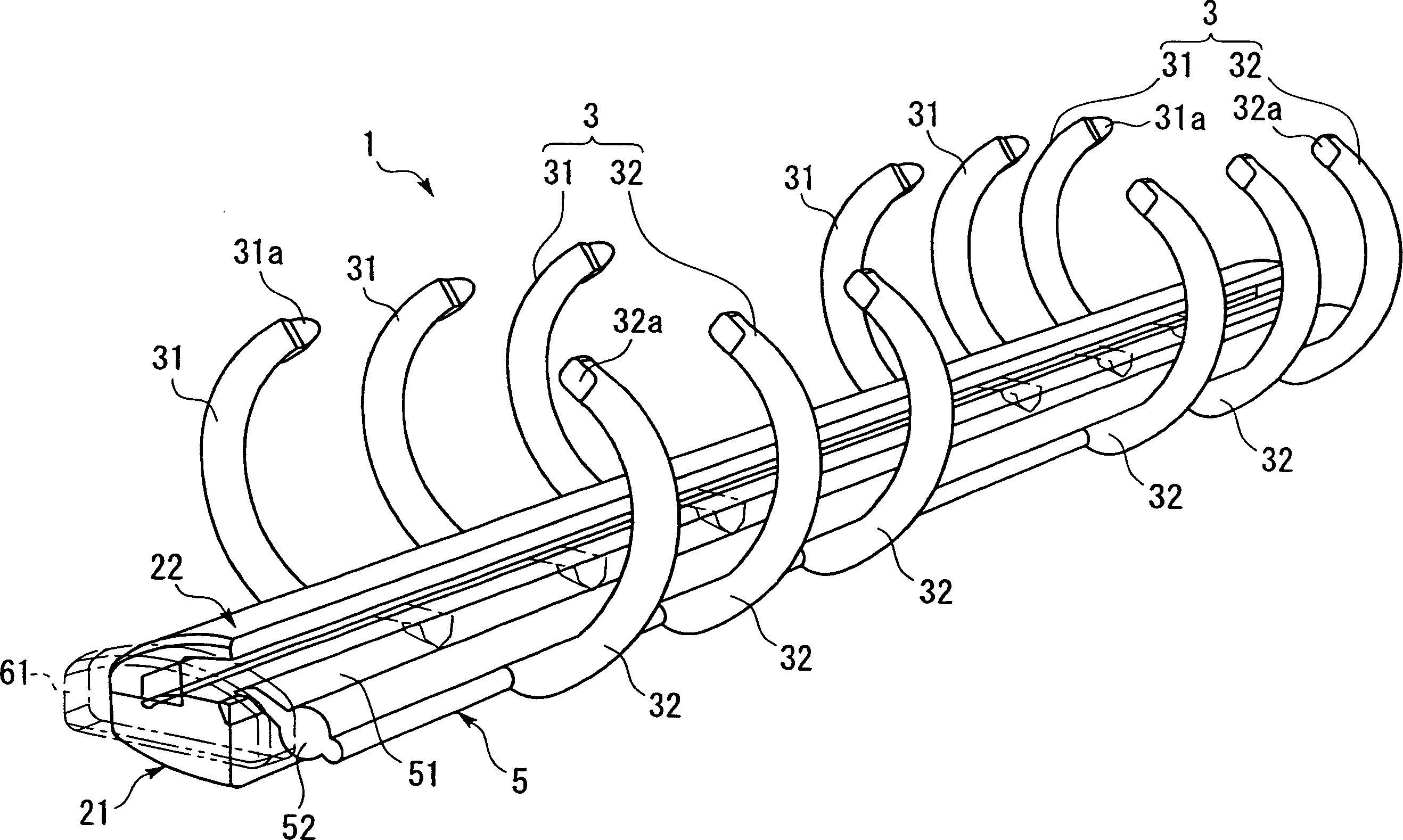

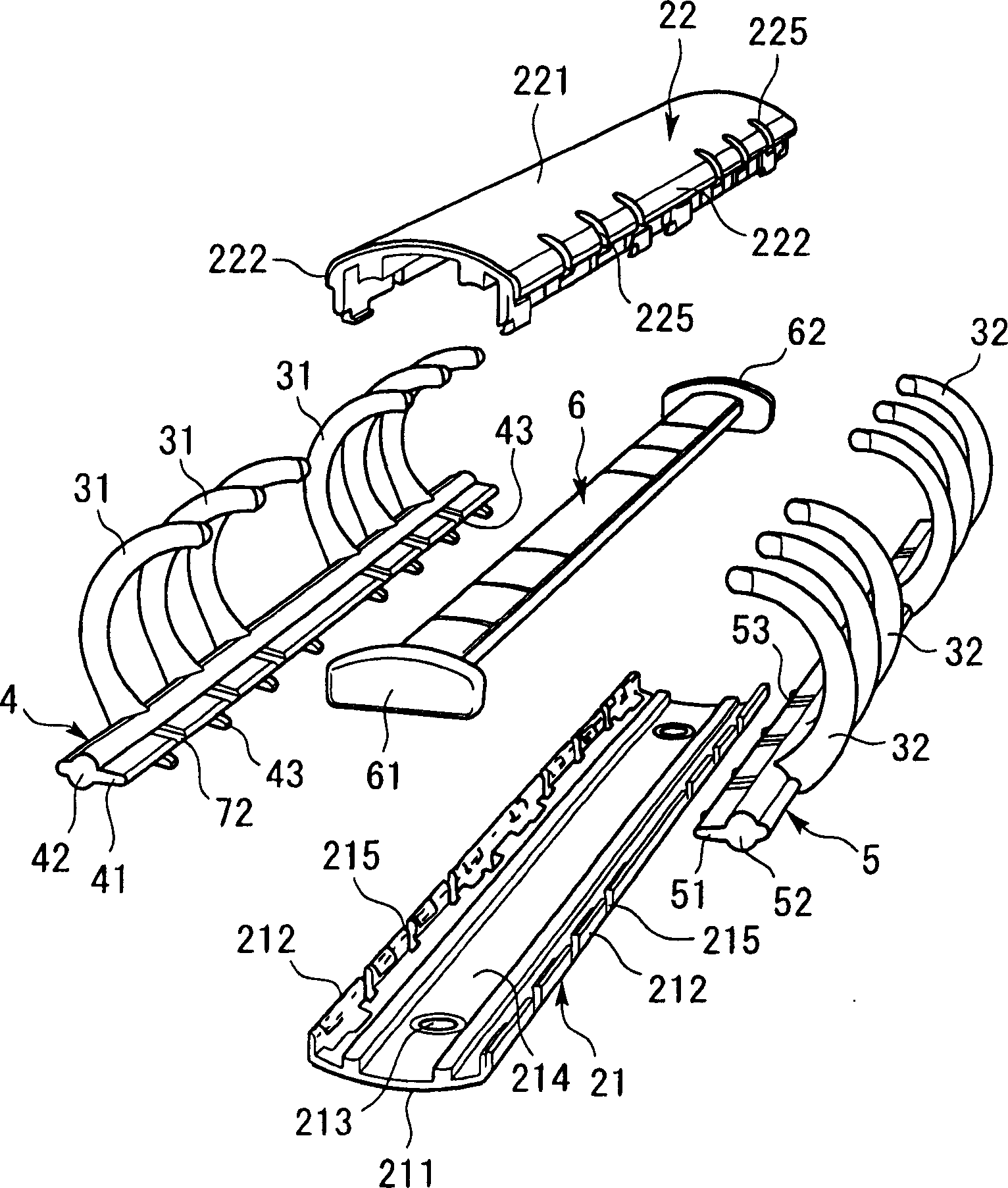

[0049] figure 1 It is a perspective view showing an embodiment in which the ring binder of the present invention is fixed to the spine cover of the cover body and used. figure 2 It is a perspective view which partially sees through and shows a ring binder. image 3 and Figure 4 is an exploded perspective view of the binder.

[0050] The ring binder 1 of the present embodiment is provided with: a base part 2 (refer to Figure 6 ), a plurality of (six) rings 3 arranged at intervals along the length direction of the base portion 2, two ring support members (the first support member 4 and the second support member 4 and the second support member) arranged in parallel in the base portion 2 member 5), an operating member 6 arranged to be capable of reciprocating movement along the longitudinal direction of the base portion 2, and a switching mechanism 7 for opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com