Microwave radiation method for preparing active carbon from biomass

A microwave radiation and biomass technology, applied in the field of material chemical industry, can solve the problems of unexplained recycling of zinc chloride raw materials, chlorine gas corrosive environment to metal materials, difficulty in mass production and automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

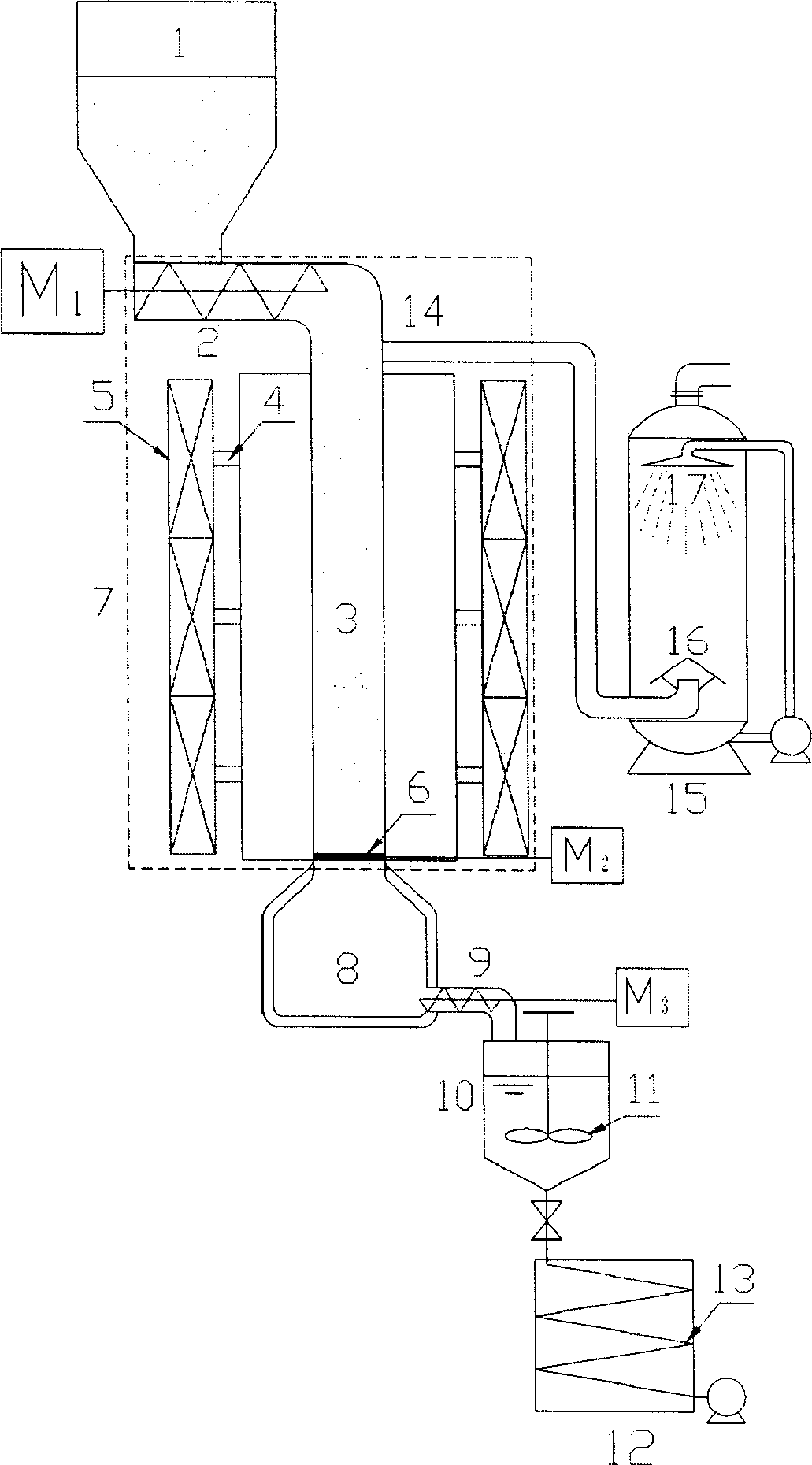

[0023] Pine sawdust was mixed with 40% zinc chloride solution and impregnated for 25 hours (the mass ratio of zinc chloride to pine sawdust was 0.75:1), and packed into the microwave reaction equipment as shown in the accompanying drawing. Set the power to 1500W, and irradiate at 600-700°C for 18min. Wash with 20% hydrochloric acid for 1 hour, and wash with water until the pH value is 7. Zinc chloride was recovered in this process with a recovery rate of 56.9%. After the material was washed with water, it was filtered and dried in a microwave oven for 5 min. Grinding to 200 meshes to obtain an activated carbon product with a yield of 37.0%. Its specific surface area is 1084m 2 / g, iodine adsorption value 1189.3mg / g, methylene blue decolorization power 135.8ml / g, benzene static adsorption capacity 47.0%. The recovery rate of zinc chloride in the spray tower is 14.5%, and the total recovery rate is 70.8%.

Embodiment 2

[0025] The pine sawdust is mixed with 50% zinc chloride solution and soaked for 15 hours (the mass ratio of zinc chloride and pine sawdust is 1:1), and packed into the microwave reaction equipment shown in Figure 1. Set the power to 10000W, and irradiate at 700-800°C for 10min. Wash with 20% hydrochloric acid for 1.5 hours, and wash with water until the pH value is 7. Zinc chloride was recovered in this process with a recovery rate of 56.3%. After the material was washed with water, it was filtered and dried in a microwave oven for 3 minutes. Grinding to 200 meshes to obtain an activated carbon product with a yield of 38.7%. Its specific surface area is 1159m 2 / g, iodine adsorption value 1191.6mg / g, methylene blue decolorization power 165.7ml / g, benzene static adsorption capacity 51.3%. The recovery rate of zinc chloride in the spray tower is 14.7%, and the total recovery rate is 71.0%.

Embodiment 3

[0027] The rice husk was mixed with 50% zinc chloride solution and soaked for 20 hours (the mass ratio of zinc chloride and rice husk was 1.5:1), and packed into the microwave reaction equipment shown in Figure 1. Set the power to 3000W, and irradiate at 600-700°C for 15min. Wash with 20% hydrochloric acid for 2 hours, and wash with water until the pH value is 7. Zinc chloride was recovered in this process with a recovery rate of 57.8%. After the material was washed with water, it was filtered and placed in a microwave oven for 7 minutes to dry. Grinding to 200 meshes to obtain an activated carbon product with a yield of 37.9%. Its specific surface area is 1397m 2 / g, iodine adsorption value 1242.5mg / g, methylene blue decolorization power 198.7ml / g, benzene static adsorption capacity 73.1%. The recovery rate of zinc chloride in the spray tower is 14.6%, and the total recovery rate is 72.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap