Method for mounting fin onto heat pipe

A technology of fins and heat pipes, which is applied in the field of increasing the contact area between fins, can solve the problems of small contact area, low heat conduction, and difficult heat circulation, etc., and achieve the effect of increasing contact area, rapid and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and technical content of the present invention will be described in detail below in conjunction with the accompanying drawings. The drawings and descriptions are provided for the purpose of illustration only and do not limit the scope of the invention in any way.

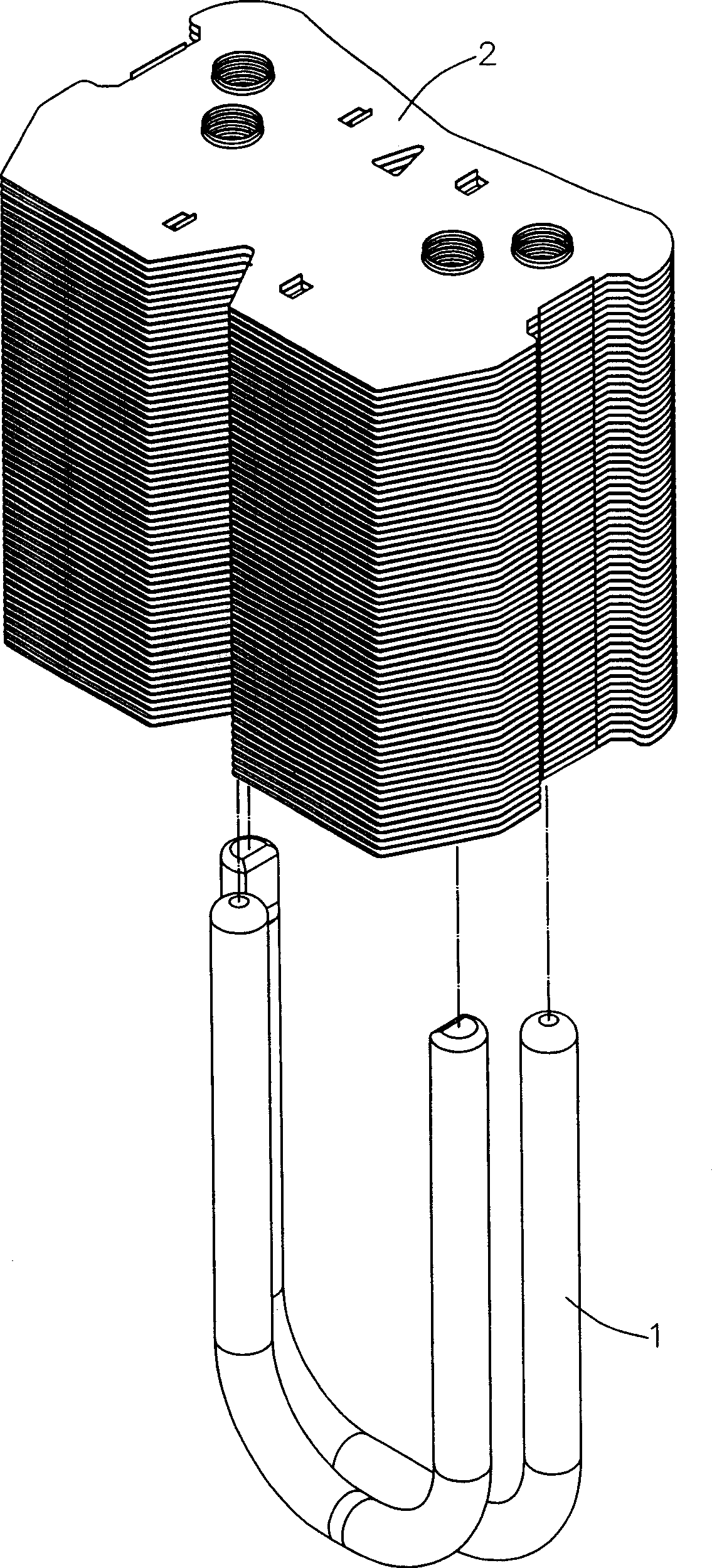

[0027] figure 1 Shown is a three-dimensional exploded view of the heat pipe and fins of the present invention. The present invention provides a method for installing fins on heat pipes, which is used to install thin fins 2 with a thickness of less than 0.2mm on heat pipes 1, so as to meet the heat dissipation requirements of the cooling end of heat pipes 1, and improve heat pipe 1 and each fin. The bonding density between sheets 2 reduces the generation of voids.

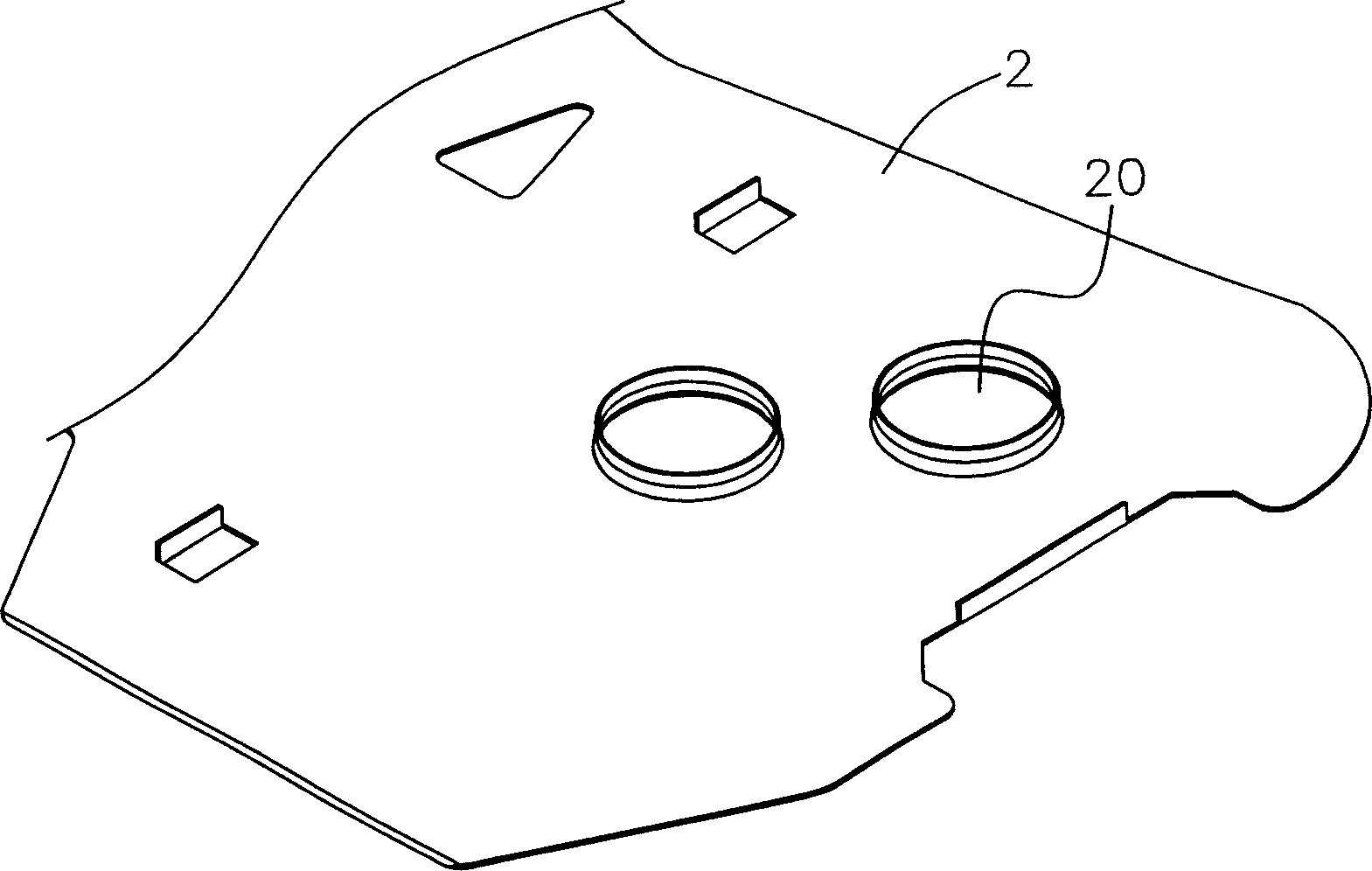

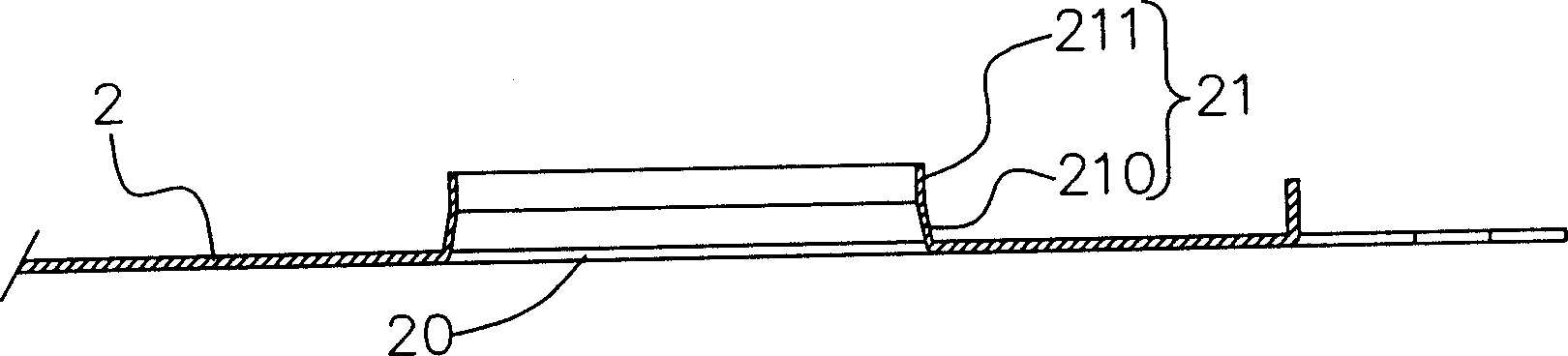

[0028] Such as figure 2 , image 3 and Figure 4 As shown, through holes 20 are first punched on each fin 2 , and the number of through holes 20 on each fin 2 depends on its matching with the heat pipe 1 . While punching through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com