Solar photovoltaic cell with micro-fluidic structure

A technology of solar panels and photovoltaic cells, which is applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems that batteries are difficult to achieve heat dissipation, and achieve the effects of improving photovoltaic conversion efficiency, accelerating heat dissipation, and saving precious metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0022] The solar photovoltaic cell provided by the invention is based on the microfluidic technology, improves the illumination and heat dissipation conditions of the solar photovoltaic cell, and improves the photovoltaic conversion efficiency.

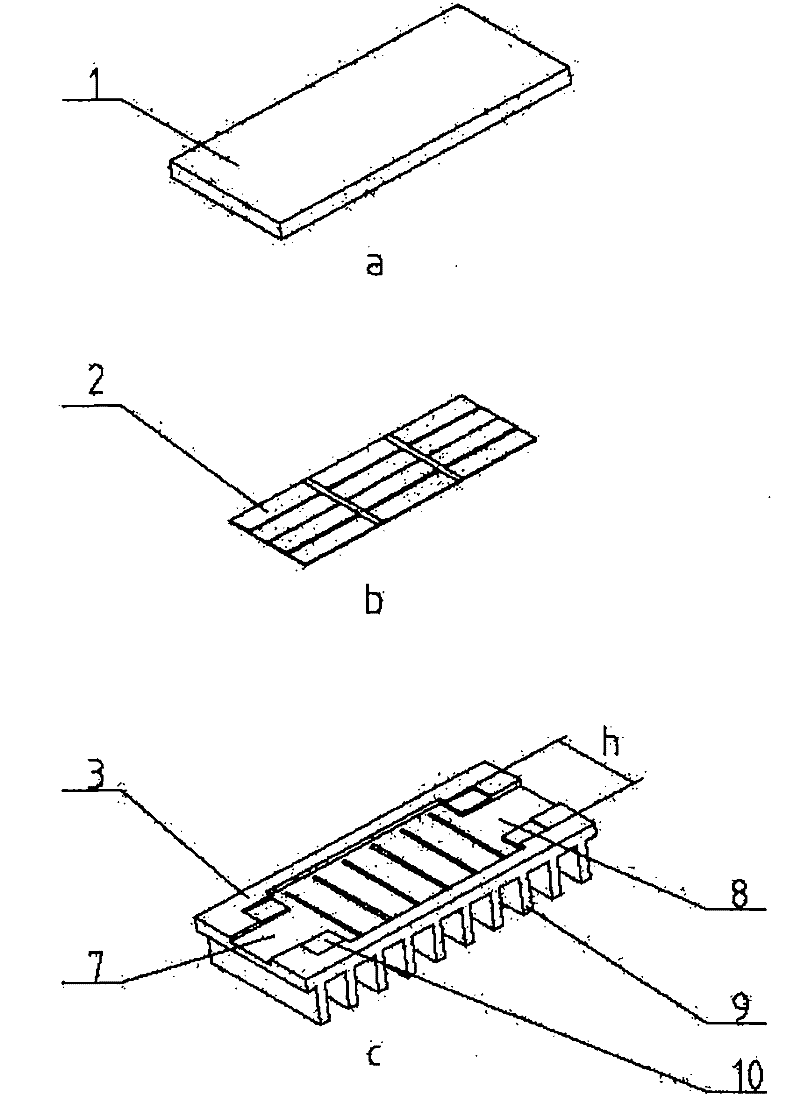

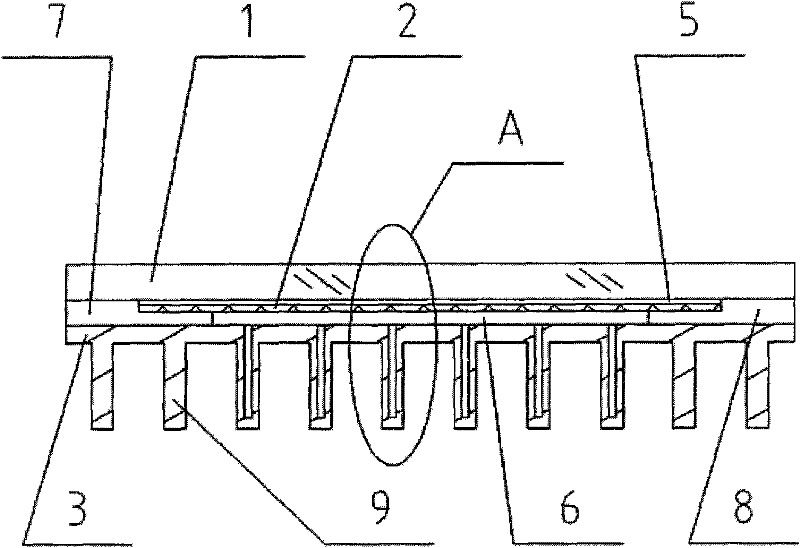

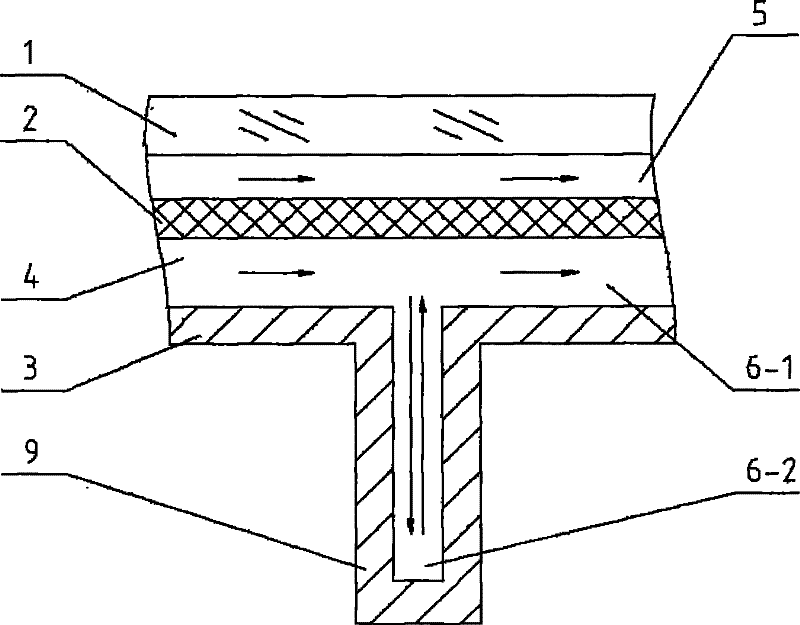

[0023] see figure 1 and figure 2 , the solar photovoltaic cell with the microfluidic structure includes, from top to bottom, an upper cover sheet 1, a solar cell panel 2 and a lower cover sheet 3, and the upper cover sheet 1, the solar cell panel 2 and the lower cover sheet 3 are stacked on top of each other. Together, the solar cell panel 2 is embedded in the lower cover sheet 3, and the upper cover sheet 1 and the lower cover sheet 3 are tightly connected and sealed through the contact surface using adhesive. The upper flow channel 5 is formed between the lower surface of the upper cover sheet 1 and the upper surface of the sola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com