A matching cooling tank structure based on stamping die

A stamping die and cooling tank technology, which is applied in the field of matching cooling tank structure, can solve the problems of poor cooling effect, single cooling method, slow cooling speed, etc., achieve rapid and uniform heat dissipation, improve heat dissipation efficiency, and increase heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

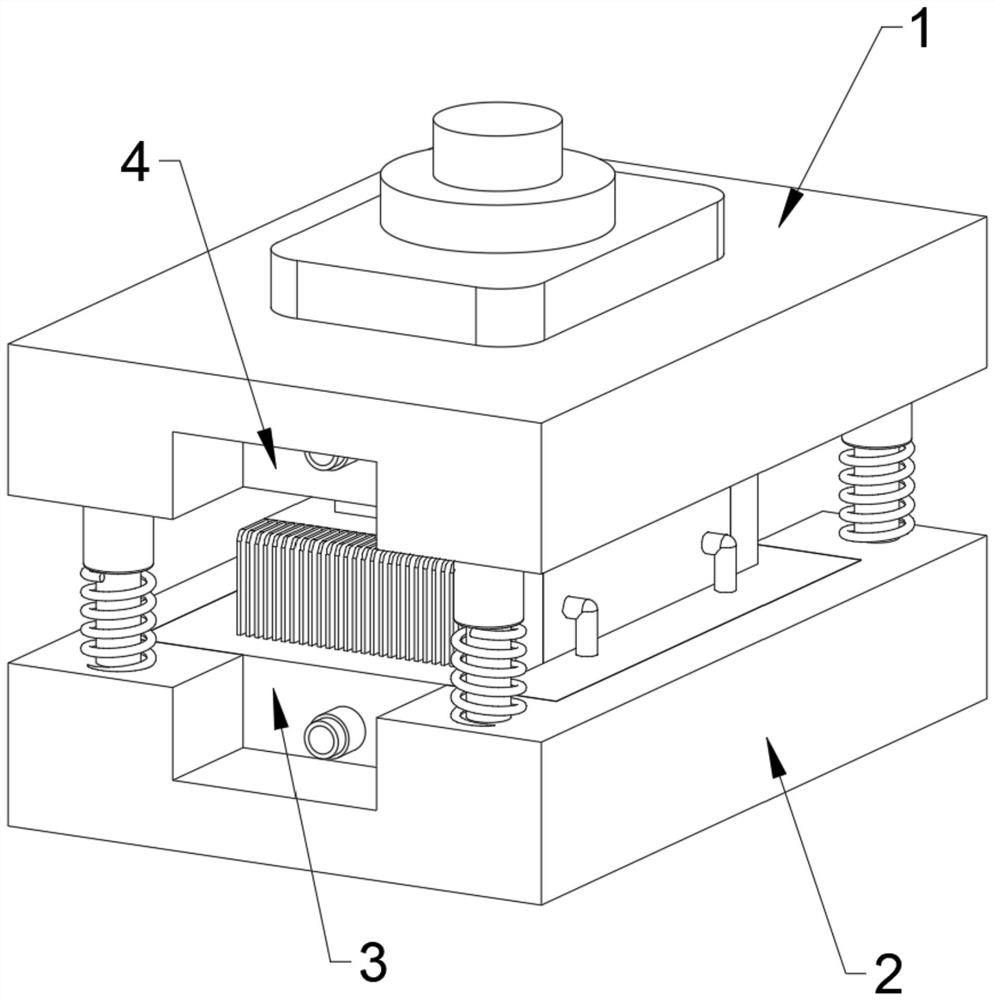

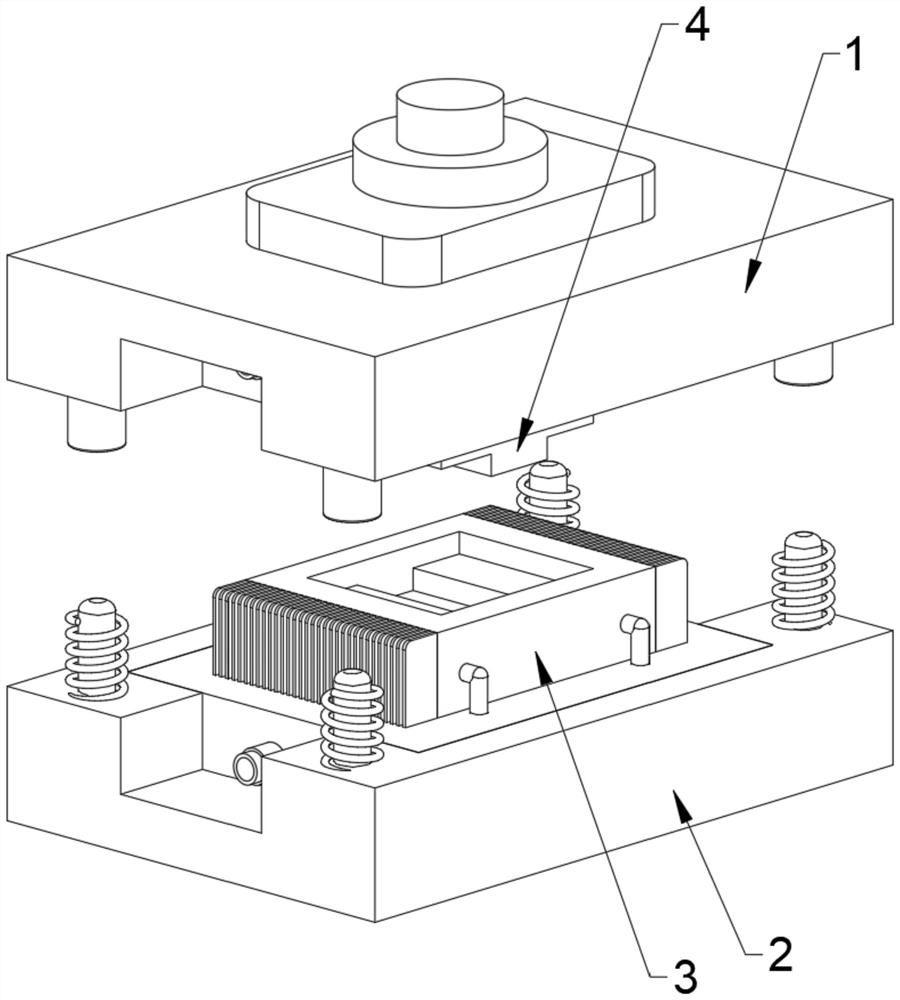

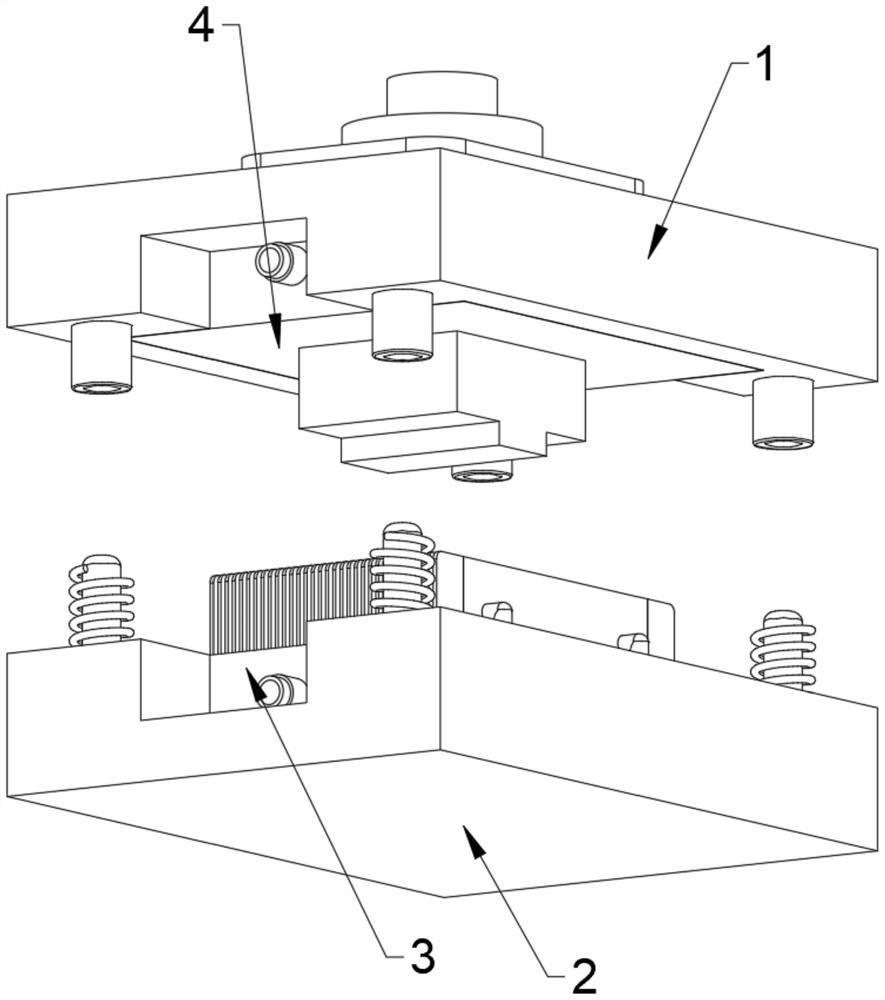

[0041] as attached figure 1 to attach Figure 10 Shown:

[0042] The present invention provides a matching cooling tank structure based on stamping dies, including: upper die fixing plate 1, lower die fixing plate 2, stamping lower die 3, cooling lower die plate 301, cooling water circulation pipe 302, and lower die cooling fins 303 , the lower mold core 304, the supporting heat dissipation column 305, the circulating cooling water chamber 306, the stamping upper mold 4, the upper mold core 401, the upper mold cooling plate 402, the mold core supporting heat dissipation plate 403 and the cooling water access pipe 5; The inner side bolt of the upper die fixing plate 1 is fixedly equipped with a stamping upper die 4, and the stamping upper die 4 is composed of an upper die core 401, an upper die cooling plate 402 and a die core supporting cooling plate 403; the lower die is fixed The inner side of the plate 2 is fixed with a lower stamping die 3, and the lower stamping die 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com