Pressing cylinder, preferably for use in a refuse compressor

A technology of garbage compressor and pressure cylinder, applied in the direction of presses, punching machines, trash cans, etc., can solve the problems of large size and weight, difficult to handle, etc., and achieve the effect of reducing transportation and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

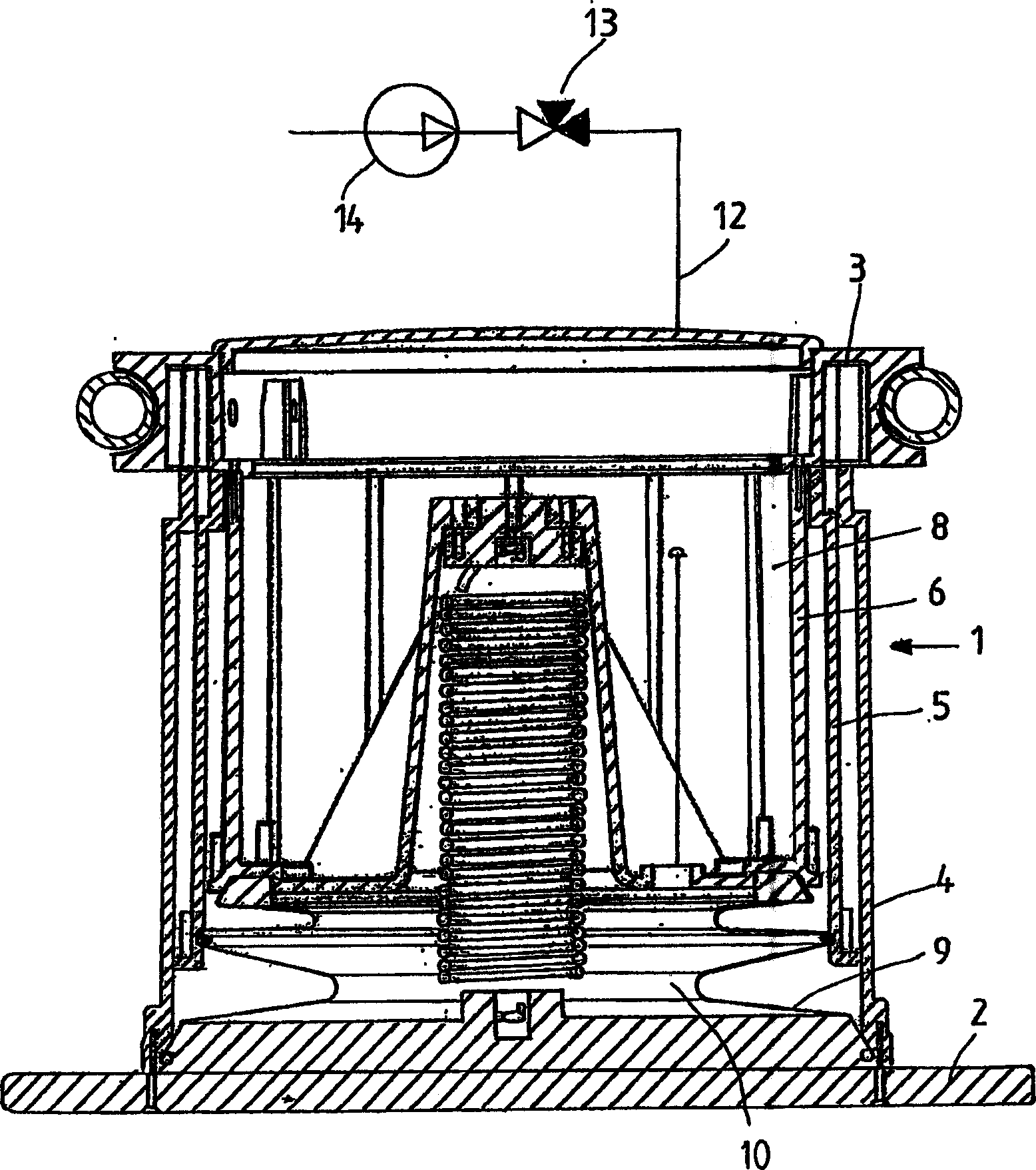

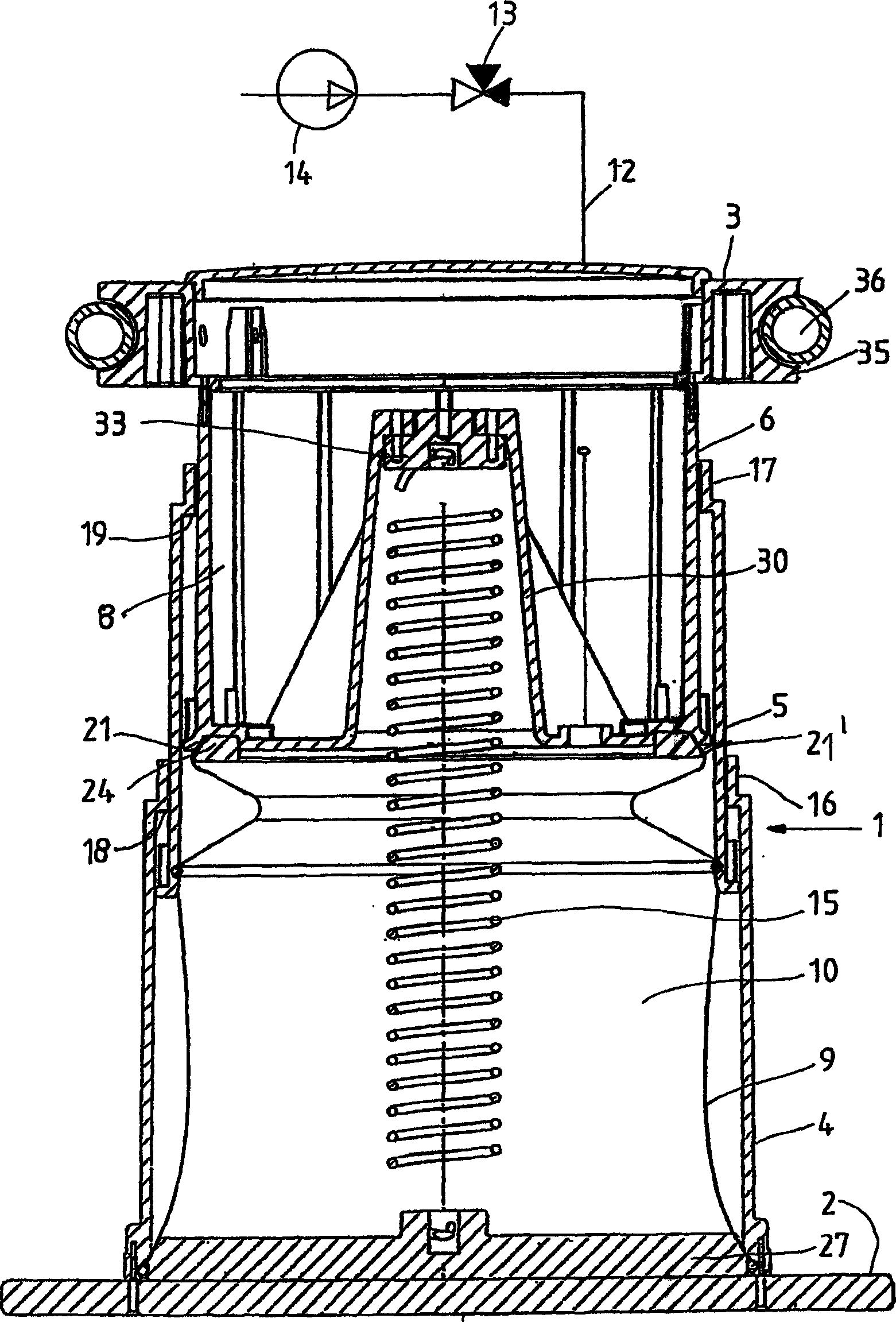

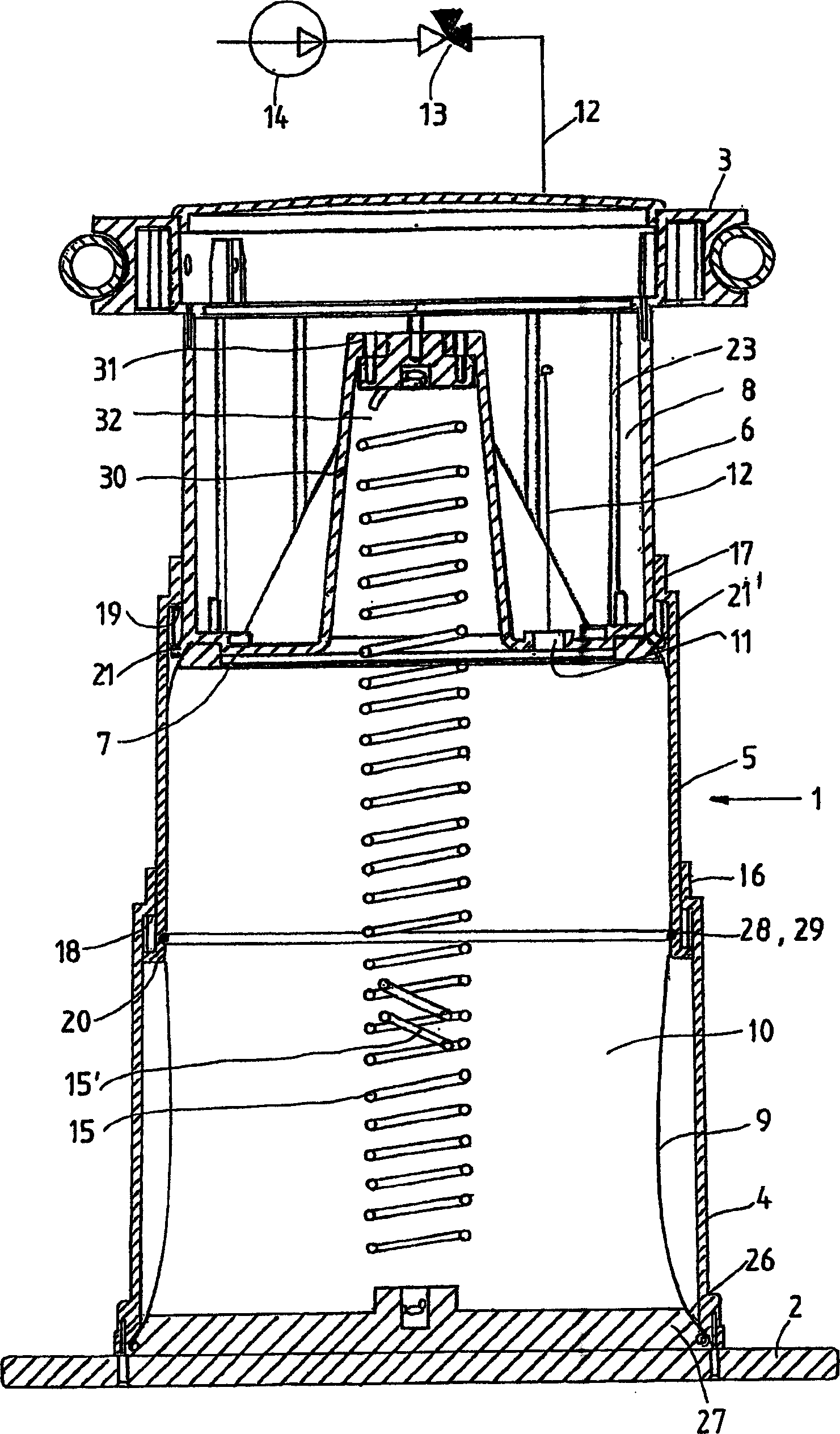

[0018] As shown in the figure, the bottom of the pressure cylinder 1 is connected with the pressing plate 2, and the top is connected with the top plate 3 fixed on the frame. The pressure cylinders are generally oriented vertically and can move the platen in an upward or downward direction.

[0019] As shown in the figure, the pressure cylinder according to the present invention is composed of many cylinder sections, preferably three sections, namely the first and bottom cylinder section 4, the second and middle section 5 and the third and upper section located at the bottom and fixed to the pressure plate 2 The cylinder section 6 and the cylinder section 5 can move telescopically along the longitudinal direction of the cylinder in the first cylinder section, and the cylinder section 6 can move telescopically in the second cylinder section. A bottom plate 7 is formed on the bottom of the third cylinder section 6 , and the bottom plate 7 together with the cylinder barrel of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com