Anti-reversal rotary device for scroll compressor

A scroll compressor, rotary device technology, applied to the components of the pumping device for elastic fluid, rotary piston pump, rotary piston machine, etc., can solve the problem of mutual collision, no compression operation, damage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

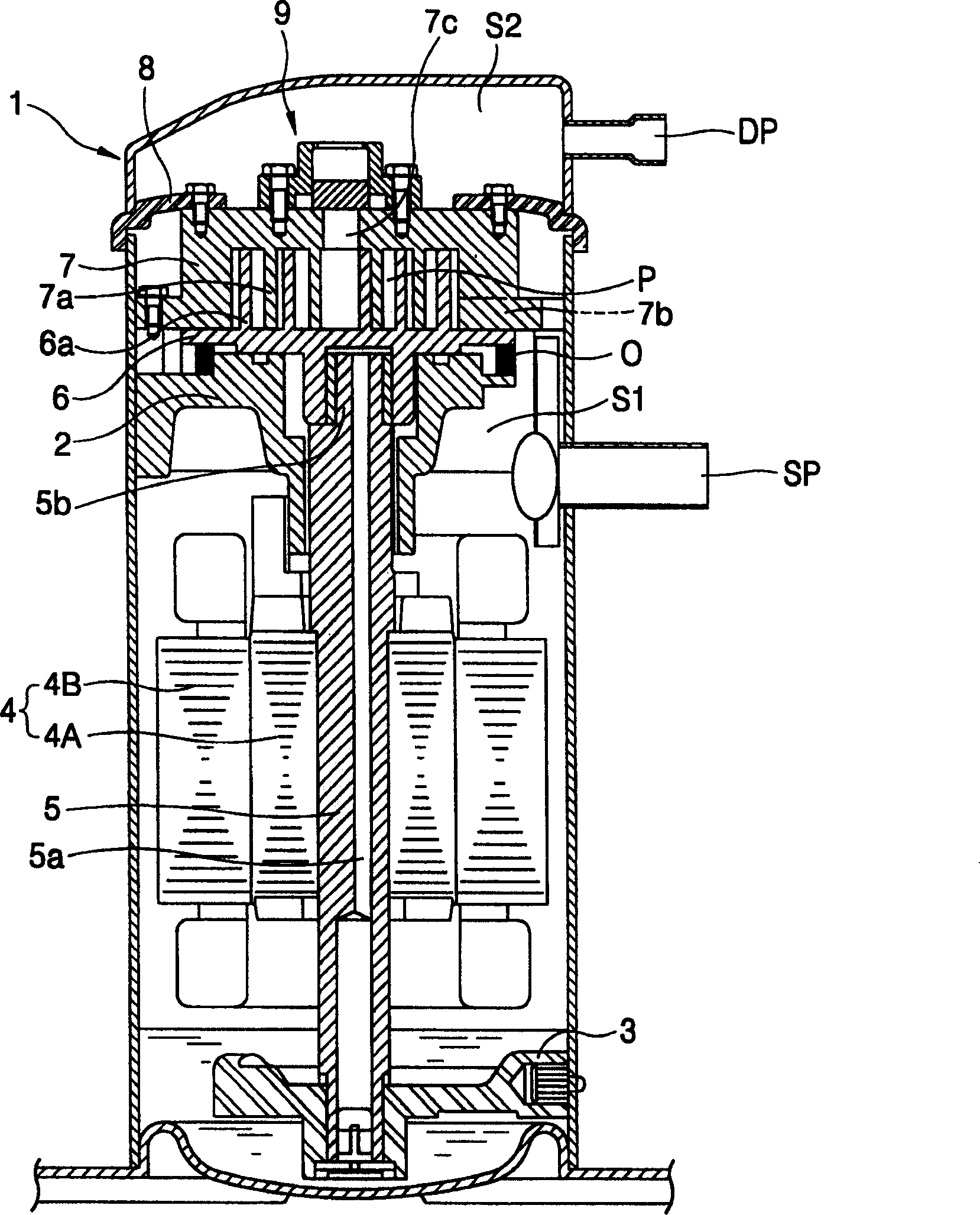

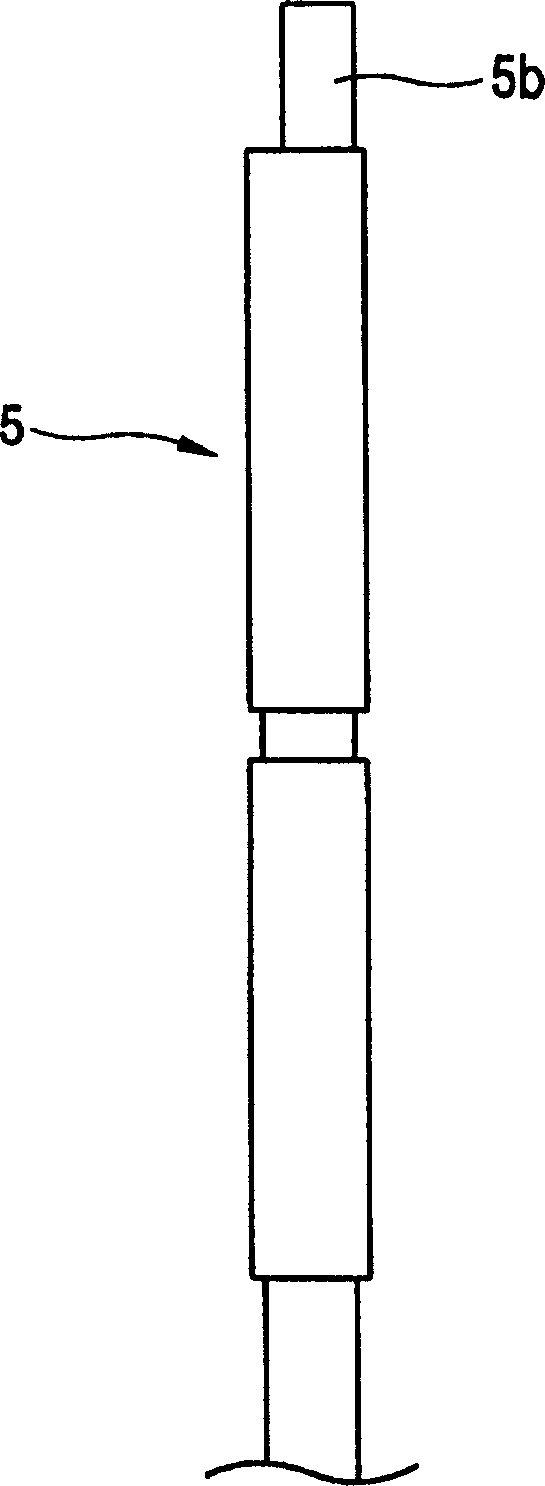

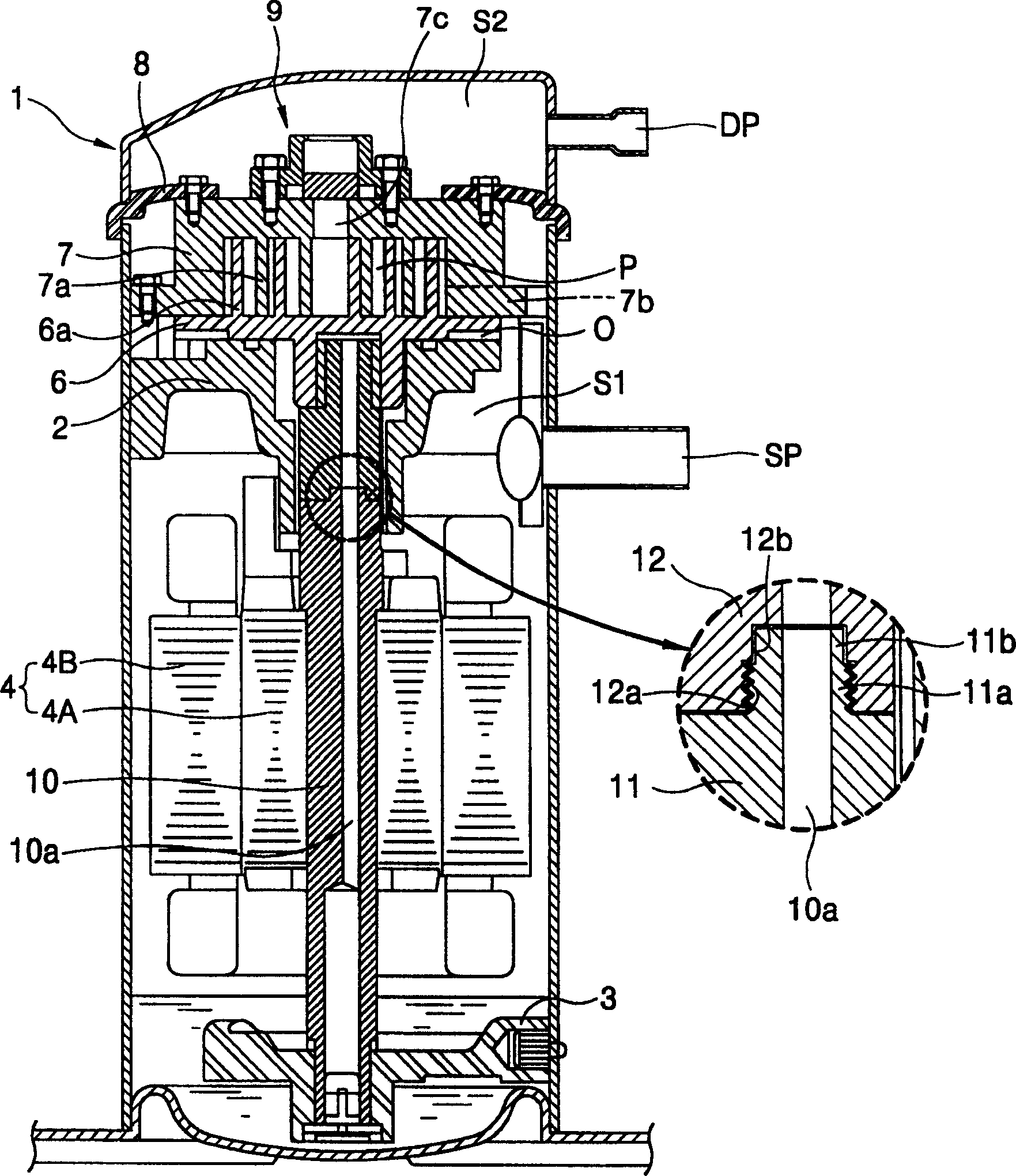

[0031] Such as image 3 , Figure 4 , Figure 5a and Figure 5b As shown, the scroll compressor provided with the anti-reverse rotation device of the present invention includes the following parts: a housing 1 provided with a gas suction pipe SP and a gas discharge pipe DP; each fixed to the housing 1 The main frame 2 and the sub-frame 3 on the upper and lower sides of the inner peripheral surface; the driving motor 4 installed between the main frame 2 and the sub-frame 3; the rotating element 4B provided on the driving motor 4 is pressed in, and is rotating The drive shaft 10 that transmits the rotating force to the rotating reel 6 described later, and cuts off the rotating force during reverse rotation; the rotating reel 6 coupled to the drive shaft 10 and arranged on the main frame 2; The above-mentioned rotating reel 6 is fixed to a fixed reel 7 on the upper surface of the main frame 2 in order to form two pairs of compression chambers P.

[0032] Such as image 3 and Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com