Lift dragging and driving mechanism

A technology of transmission mechanism and traction mechanism, which is applied to elevators, transportation and packaging in buildings, etc., can solve the problems of large space occupied by elevators and increase the cost of elevator construction, and achieve the effect of saving installation and use costs and preventing shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

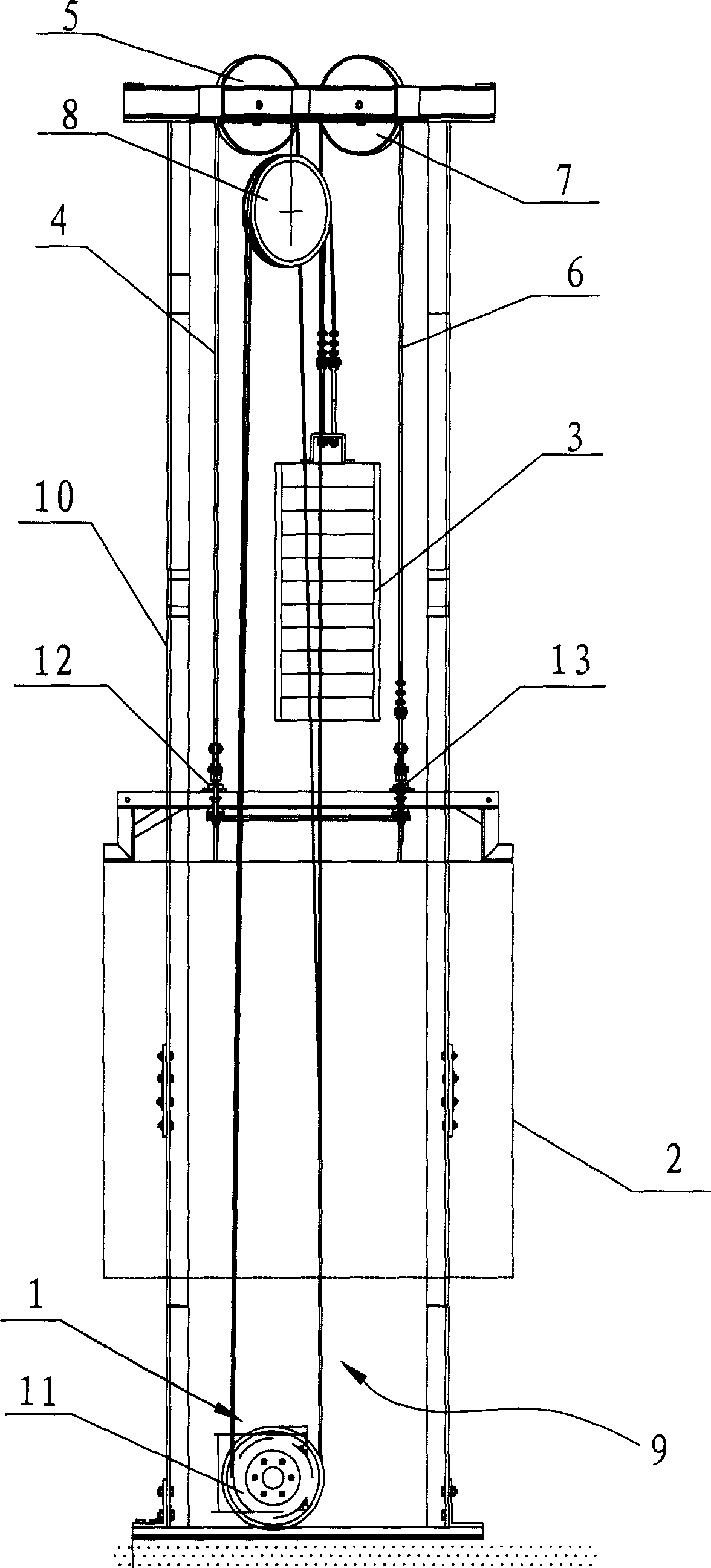

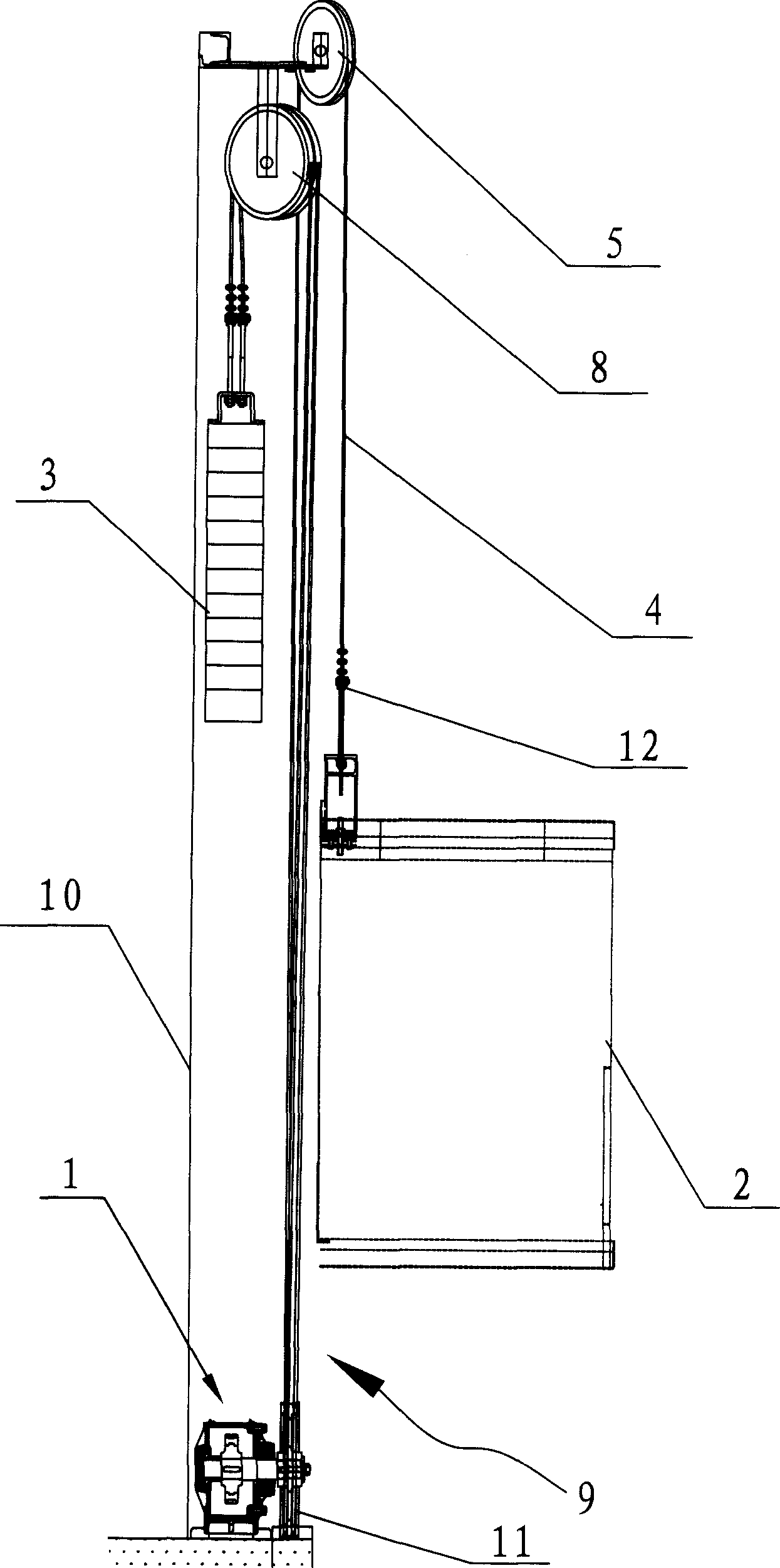

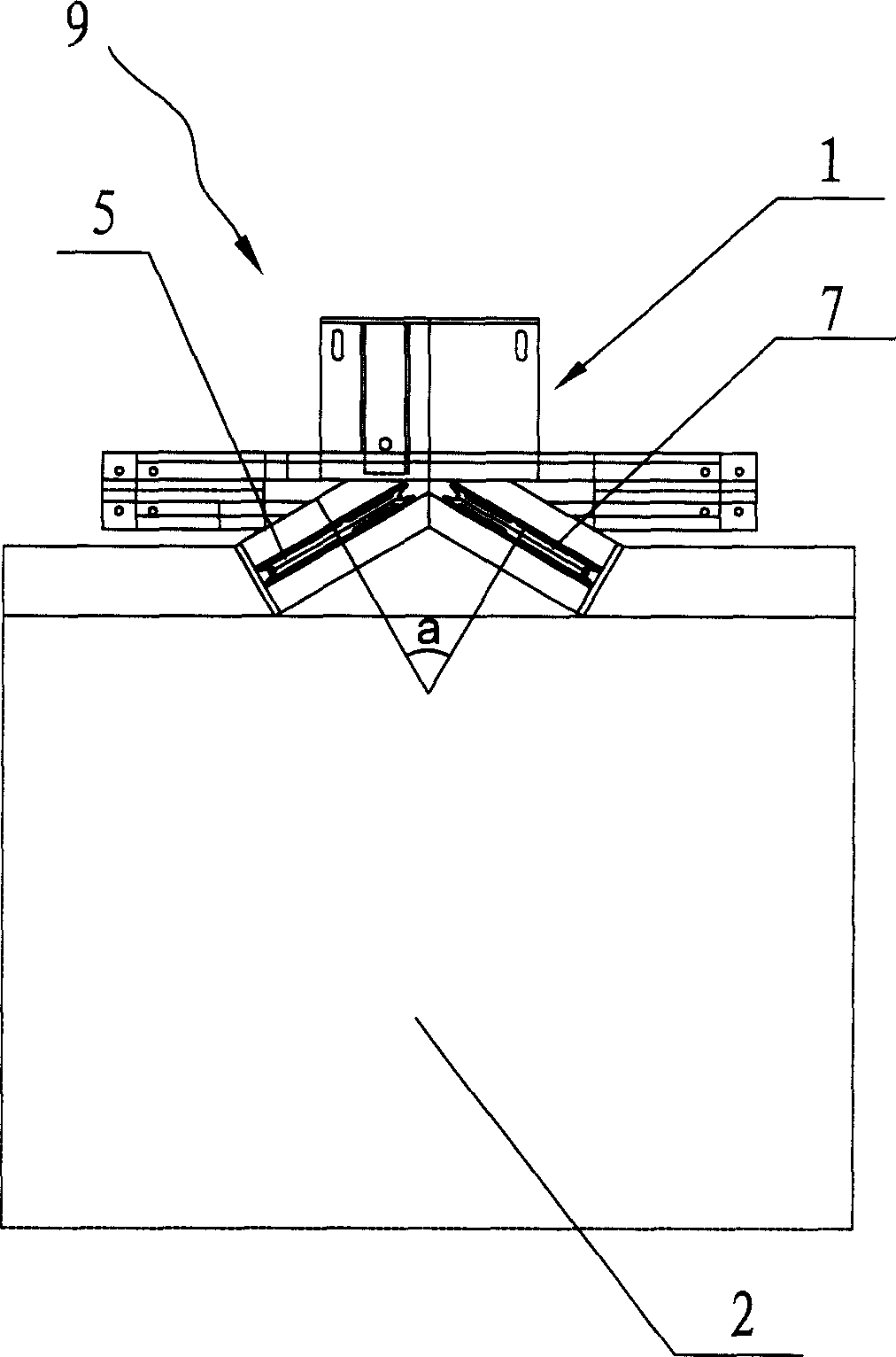

[0015] See attached figure 1 - attached image 3 As shown, a traction transmission mechanism of an elevator includes a traction motor 1, a car 2 that is drive-connected with the traction motor 1 through a traction mechanism 9, and the rotor of the traction motor 1 is connected in transmission There is an output turntable 11, the traction mechanism 9 includes a first traction rope 4 and a second traction rope 6 wound on the output turntable 11, and a fixed pulley for the first traction rope 4 to go around The first pulley 5, the second pulley 7 used as a fixed pulley for the second traction rope 6 to go around. Both sides of the top end of the car 2 are respectively symmetrically provided with a first connecting bracket 12 and a second connecting bracket 13, and one end of the first traction rope 4 protrudes from the output turntable 11 and connects with the second A connection bracket 12 is connected, and one end of the second traction rope 6 protrudes from the output turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com