Two-edge internal-washing wiper

A wiper and wash-type technology, applied in the field of double-blade inner-wash wipers, can solve the problems such as the difficulty of spraying the cleaning liquid in an all-round, uniform and effective manner, the front angle is smaller than the rear angle or one-sided fall, and the rubber edge is damaged, etc. , to achieve the effect of reducing kink, improving scraping and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail:

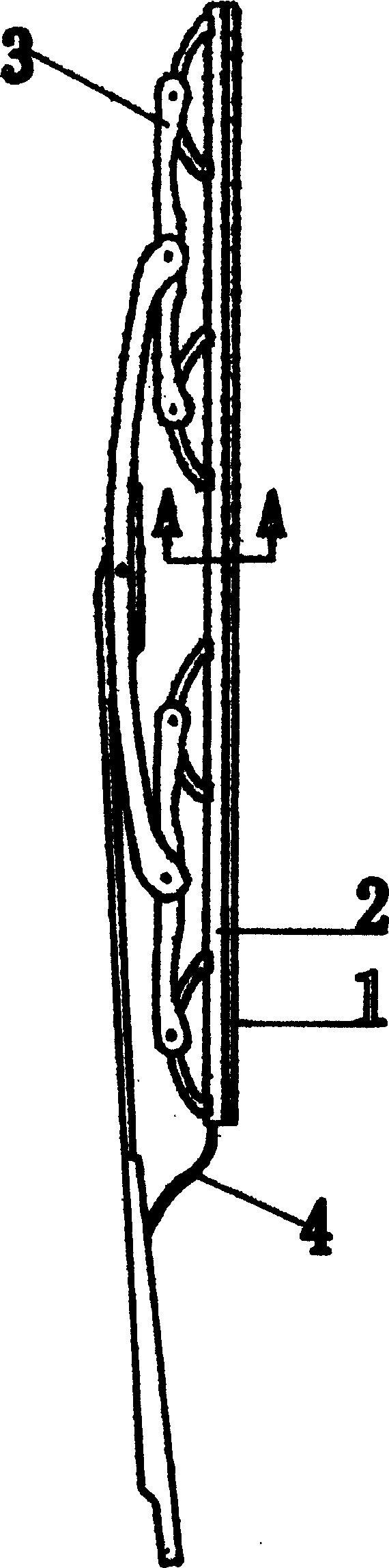

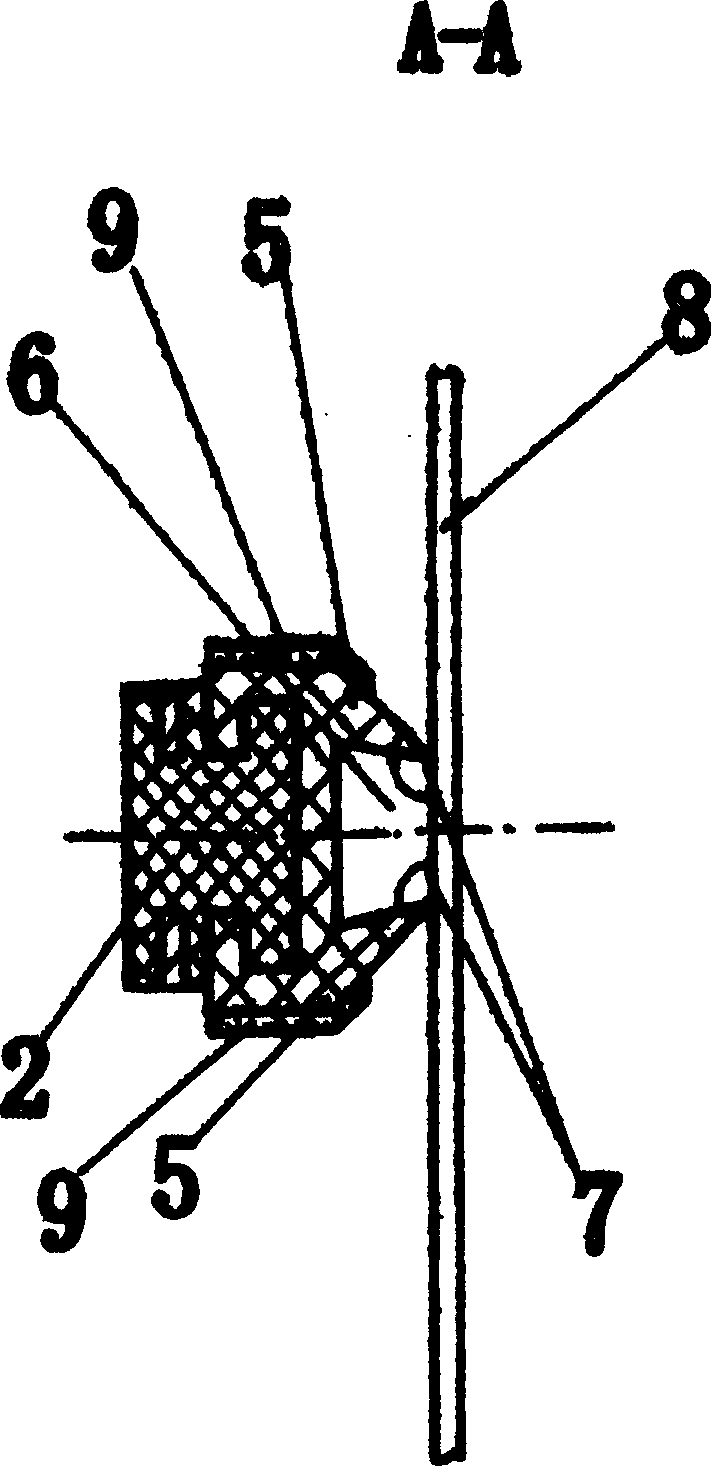

[0009] Refer to attached figure 1 with 2 , The double-edged internal wash wiper is composed of a rubber strip 1, a bracket 2, a rocker arm 3, and a cleaning fluid conduit 4. A cleaning tank 6 is provided at the bottom of the rubber strip 1 . The rubber strip 1 is installed on the bracket 2, and can be easily removed from the bracket 2 for replacement when damaged. The rubber strip 1 and the support 2 can also be made into one body, and are directly installed on the rocker arm 3 . The cleaning liquid conduit 4 is fixed on the rocker arm 3, and its function is to divert the pressurized cleaning liquid into the cleaning tank 6, and the cleaning liquid will be evenly and effectively sprayed on the windshield as it swings from side to side during the work of the present invention. Glass 8 on. Two sidewalls of the cleaning tank 6 are edge edges 5, and the edge edge 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com