Quick railway goods train bogie

A railway freight car and bogie technology, which is applied in the field of high-speed railway freight car bogies, can solve the problems that the braking performance cannot meet the requirements of fast running of the vehicle, the stability and safety of the vehicle need to be improved, and the dynamic performance of the bogie is deteriorated. Achieve the effect of reducing maintenance workload, improving operational reliability and safety, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

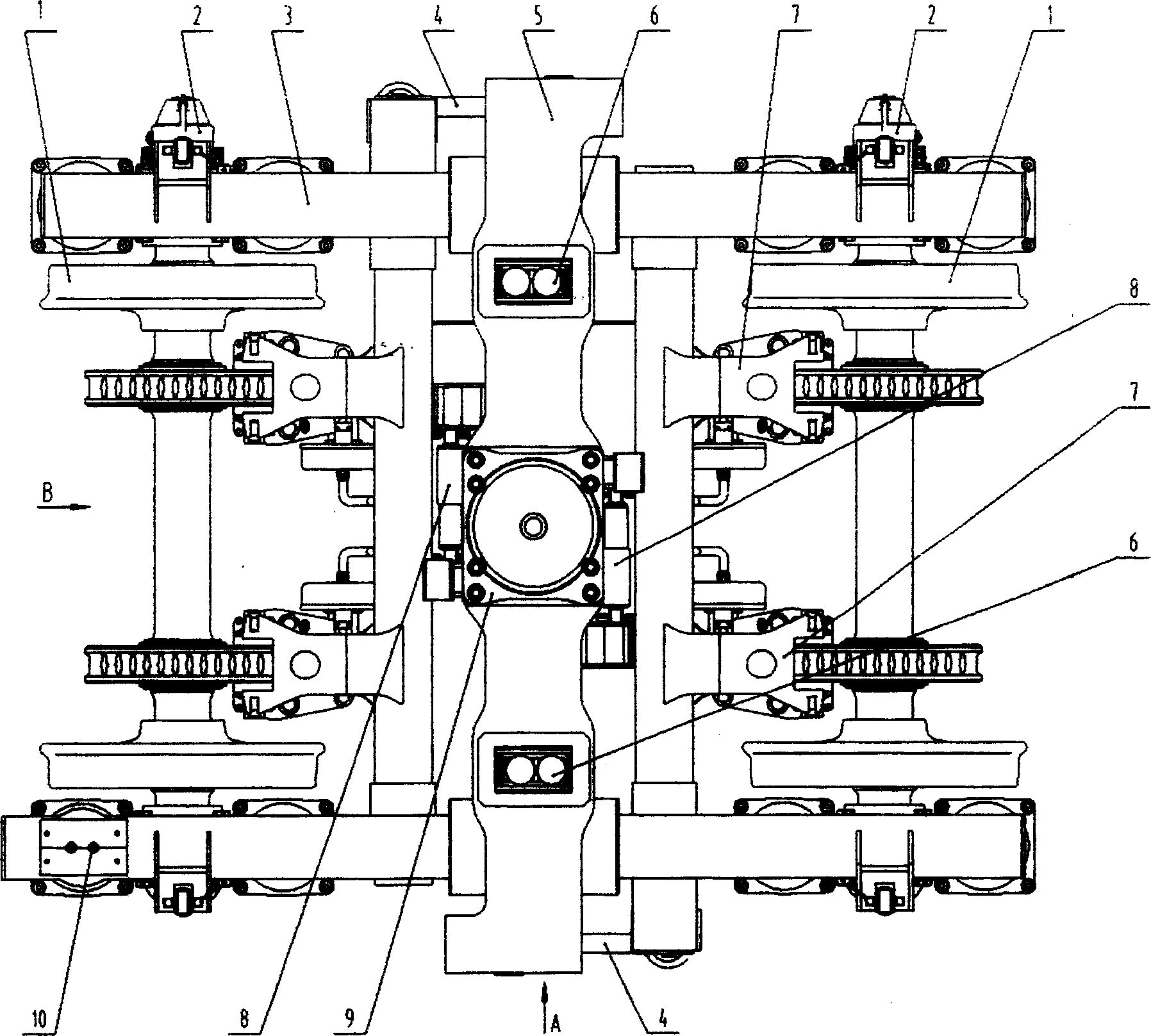

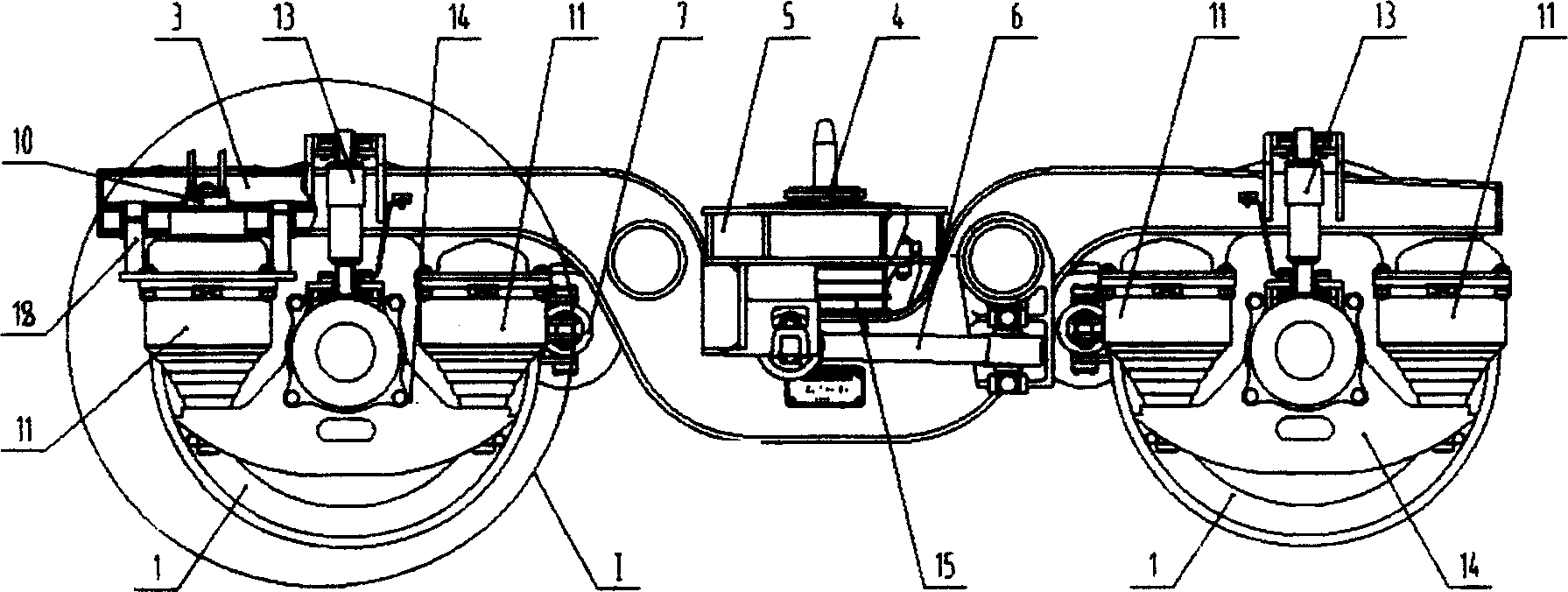

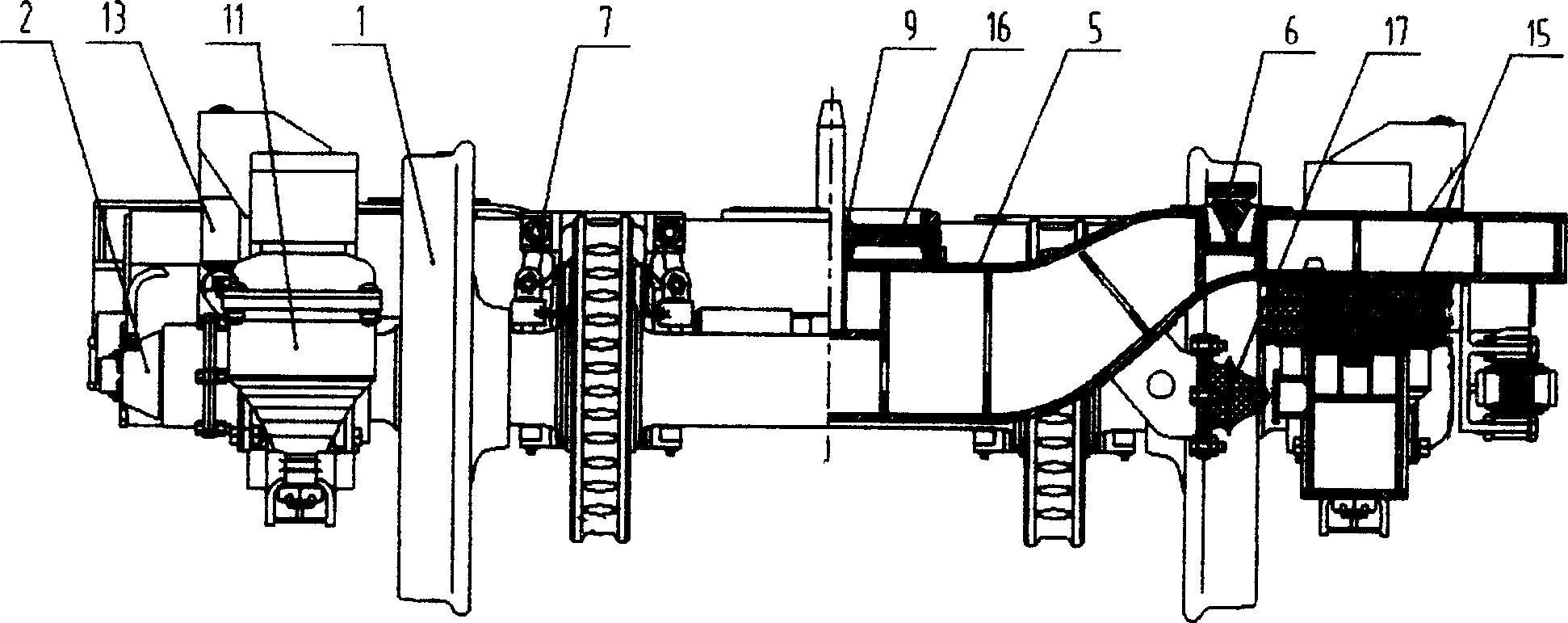

[0022] Referring to the accompanying drawings, the present invention includes a wheel set 1, a frame 3, a bolster 5, a suspension device and a foundation braking device 7. The basic braking device 7 adopts a unitary disc brake machine, which includes a brake disc 23 installed on the wheel set axle, a brake cylinder 36, a clamp assembly 35, and a brake shoe 34. The clamp assembly 35 is installed on the on framework 3. Its key technology is that suspension device adopts two-line suspension, and one-line suspension device (axle box suspension device) 14 adopts metal liquid rubber composite spring 11 and axle box location, is positioned between frame 3 and wheel pair 1 axle box. The metal liquid rubber composite spring 11 is provided with a liquid chamber at the upper end and the middle of the conical metal rubber spring 27, and a damping liquid 26 and a damping hole 25 are arranged in the liquid chamber, and a compensation chamber 24 is provided at the upper end of the liquid cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com