A turnout for increasing train lateral passing speed

A technology of turnout and speed, which is applied in the field of turnout for improving the lateral speed of trains, can solve the problems of increase in manufacturing cost of turnout, difficulty in design and construction, increase in length and area of turnout, etc., and achieve structural reliability enhancement and maintenance reduction. The effect of maintenance and improvement of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

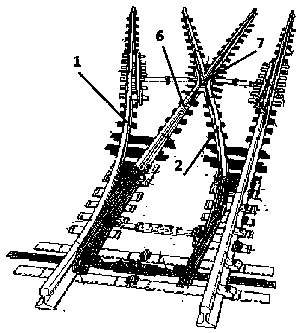

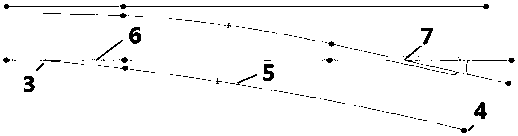

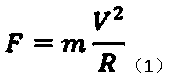

[0015] The present invention provides to solve the above-mentioned technical problems. The present invention provides a single turnout for increasing the lateral passing speed of trains, including curved strands and straight strands. The curved strands include inner rail 1 and outer rail 2, and the horizontal elevation of outer rail 2 is different. , the horizontal height of the inner rail of the turnout is reduced according to the passing speed of the train and the radius of the guide curve, and the maximum reduction value h is

[0016]

[0017] Among them, R is the radius of the curve of the curved strand, V is the passing speed of the train, S1 is the gauge of the track, and g is the acceleration due to gravity.

[0018] On the basis of the above scheme, the reduction of the horizontal height of the inner rail 1 of the curved strand is gradually reduced from the beginning of the guide curve of the curved strand to the maximum value h in the middle area of the turnout, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com