Purification equipment and two-chamber type gas stripping equipment thereof

A gas lift and equipment technology, applied in the field of two-chamber gas lift equipment, can solve problems such as sludge concentration control that is difficult to achieve differentiation, and achieve the effect of reducing maintenance and repair, saving investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

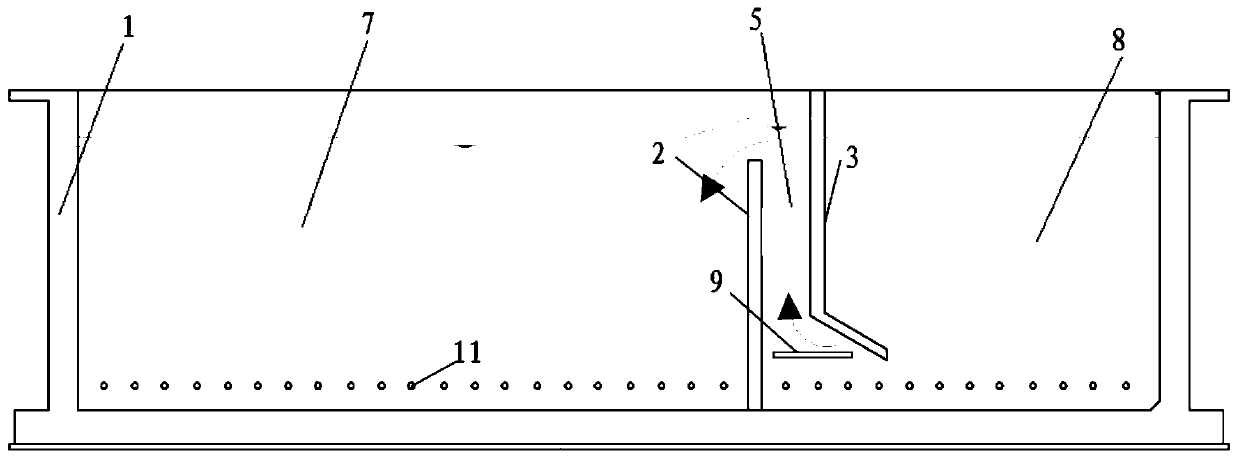

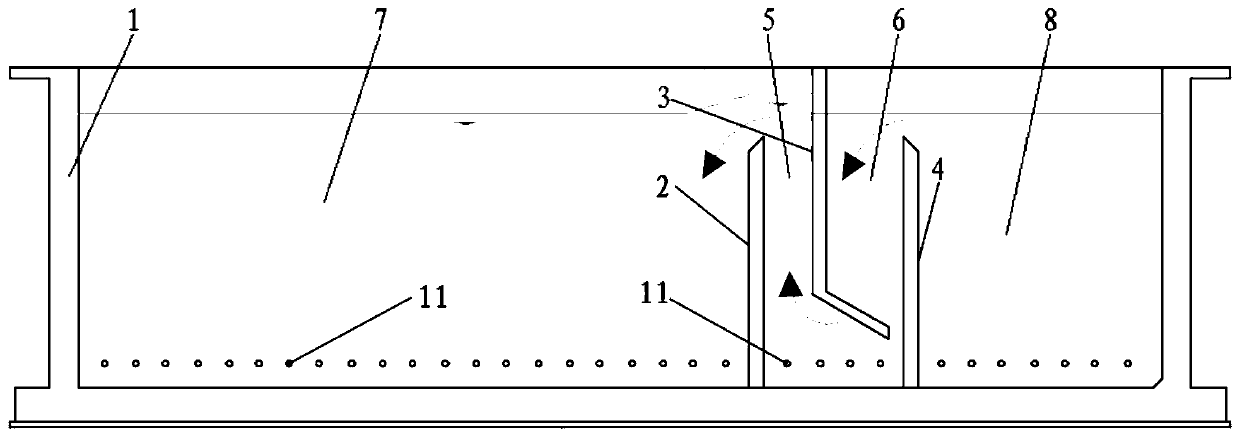

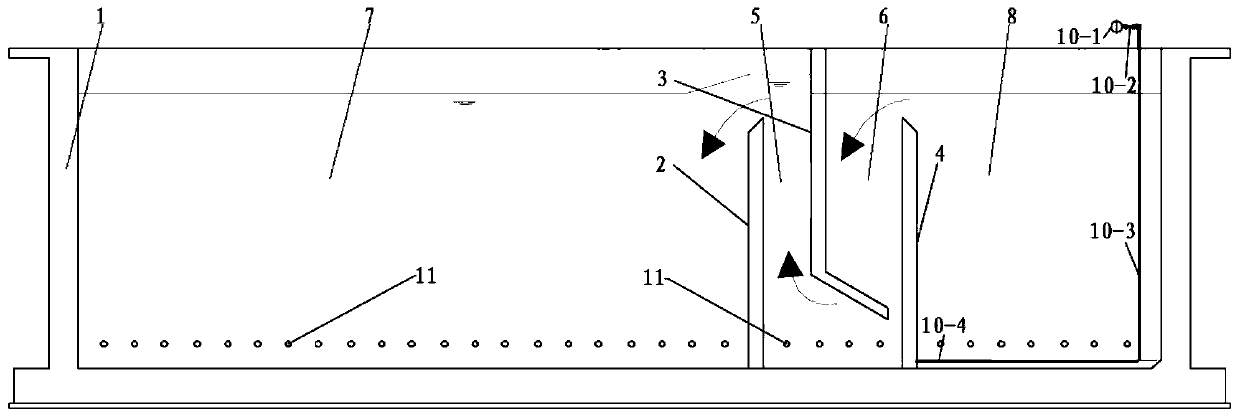

[0041] Its specific work implementation method is as follows:

[0042] as attached image 3 Shown: The air delivered by the blower through the air supply main pipe 10-1 is delivered to the air stirring device at the bottom of the second functional area 8 through the control valve 10-2 through the air supply branch pipe 10-3; the second functional area The amount of gas released by the air stirring device at the bottom of 8 directly determines the expansion height of the sludge bed at the bottom of the second functional area 8, and also directly determines the sludge concentration at the top of the second functional area 8. Therefore, by adjusting the control valve 10-2 The amount of air input to the air stirring device at the bottom of the second functional area 8, so as to realize the high and low concentration of the sludge entering the air release chamber 6 in the second functional area 8, so as to realize the first functional area 7 and the second functional area. Differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com