Design and manufacture aiding apparatus, aiding program and aiding method

A support device and storage device technology, applied in manufacturing computing systems, calculations, special data processing applications, etc., can solve problems such as design difficulties, display methods of chemical substance accumulation method results that do not record the parts list display method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

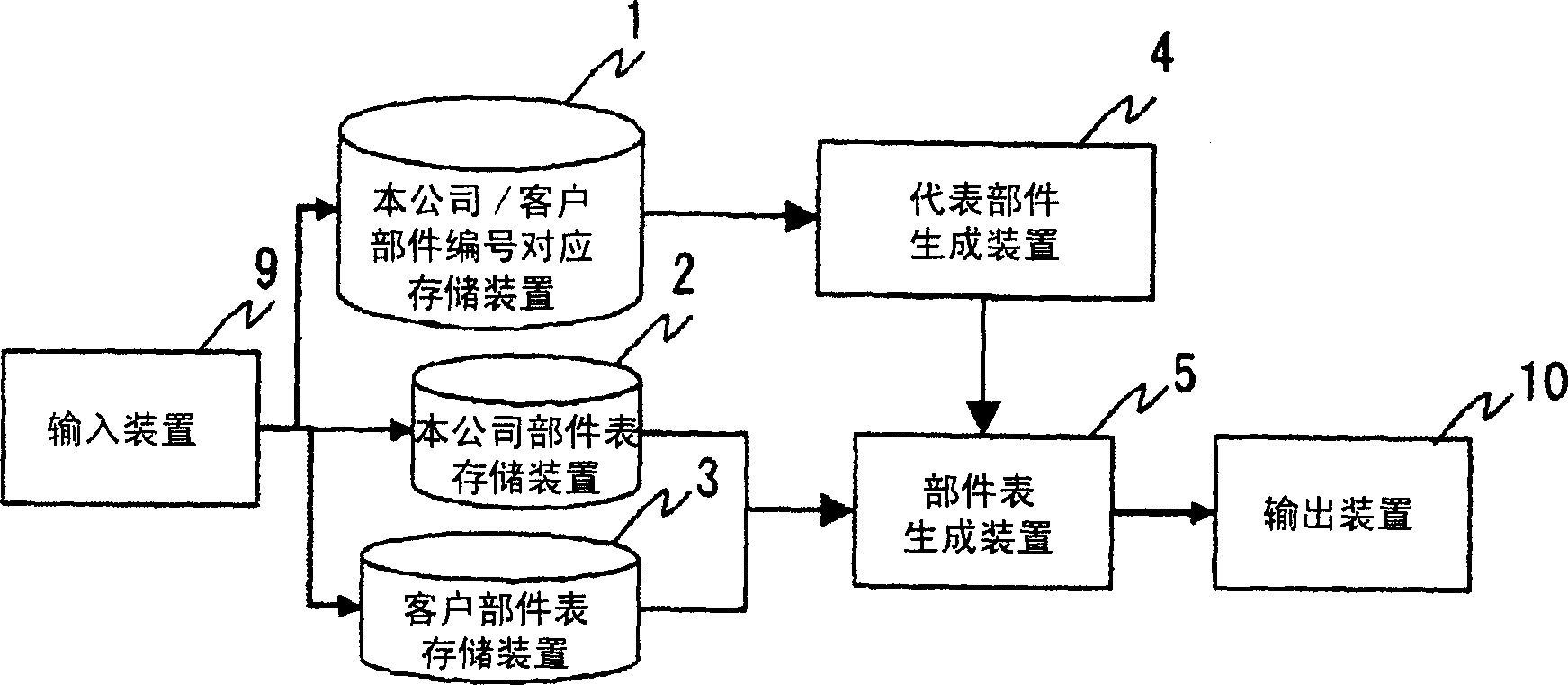

[0065] figure 1 It is a block diagram showing the structure of the first embodiment of the design and manufacture support device of the present invention.

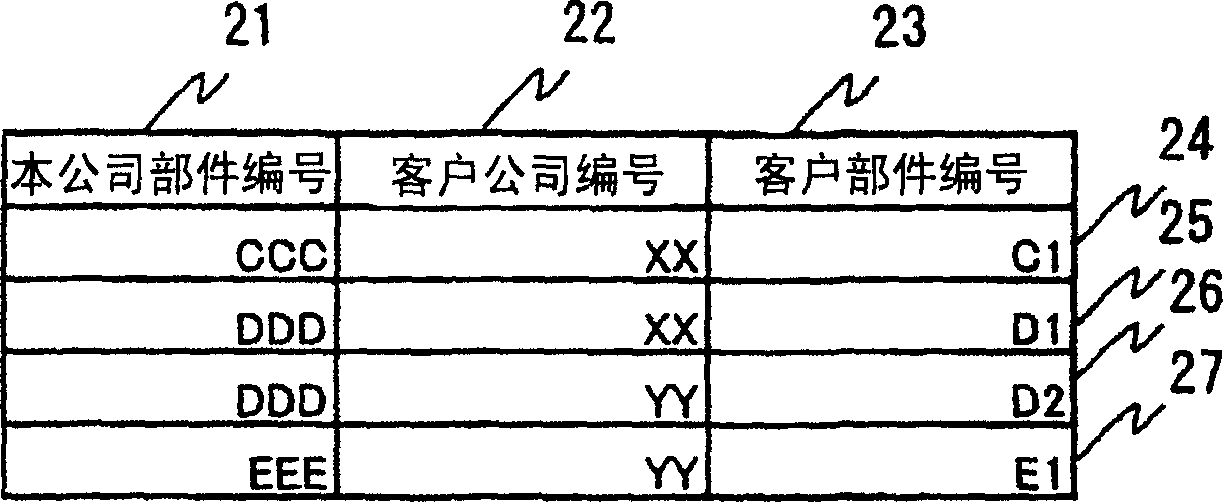

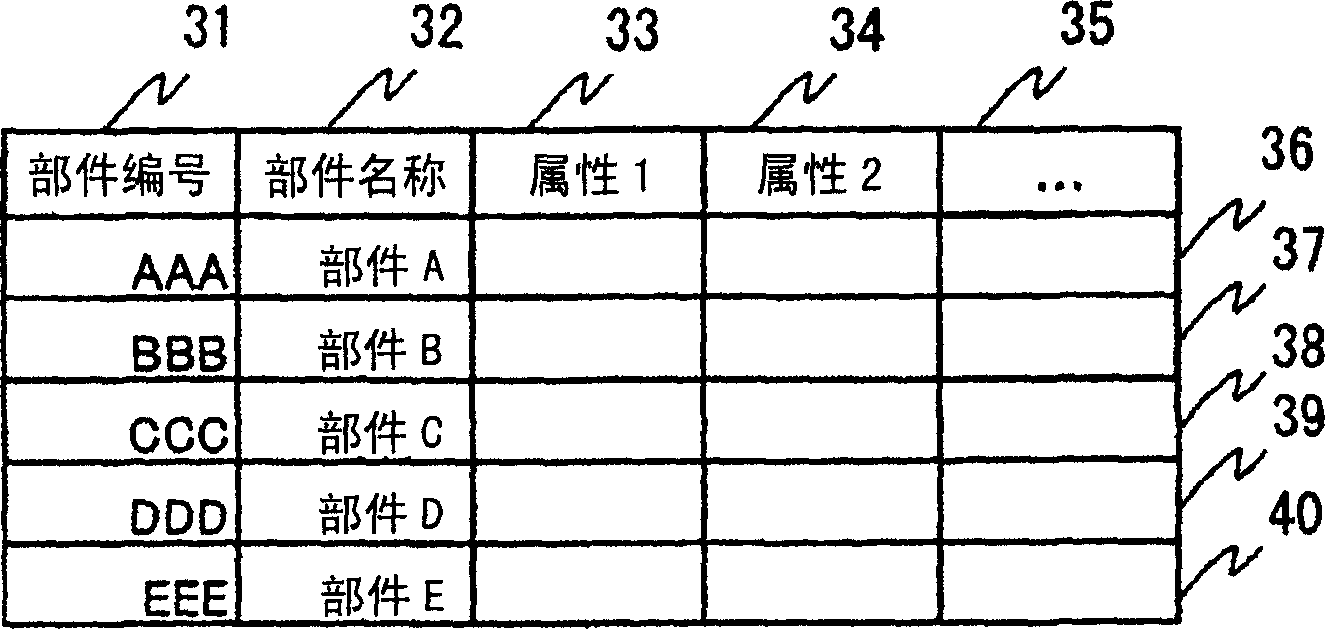

[0066] figure 1 The design and manufacturing support device includes: the company / customer part number correspondence storage device 1, which stores the corresponding part numbers of the company's parts and customer parts; the company's parts list storage device 2, which stores the part composition of the company's products; Table storage device 3, which stores the composition of parts purchased from customers; representative part generation device 4, which generates representative parts according to the corresponding part numbers of the company / customer; parts list generation device 5, which generates representative parts according to the The representative parts generated by the generating device, the company's parts catalog stored in the company's parts catalog storage device, and the customer's parts catalog stored in...

Embodiment 2

[0120] Next, use Figure 17 A second embodiment will be described. and figure 1 Compared with the first embodiment shown, there is no representative parts generation device 4, the parts list generation device 5 becomes the parts list generation device 5', and the parts attribute storage device 6, the part attribute retrieval device 7 and the product attribute accumulation device 8 are newly added. composition.

[0121] The reason why this structure is implemented is that by combining the company's parts list and the customer's parts list, the attribute value of the product is accumulated from the attribute value of the part for the part of the customer. In the description of the following embodiments, the accumulation of chemical substances is taken as an example, but the attribute values to be accumulated are not limited to chemical substances, and may be product quality, environmental load evaluation, recyclability evaluation, and the like.

[0122] The newly added cons...

Embodiment 3

[0161] Next, use Figure 29 A third embodiment will be described. and figure 2 Compared with the second embodiment shown, the newly added structure is the representative parts generating device 4, and the parts list generating device 5' is changed to the parts list generating device 5, and the product attribute accumulating device 8 is changed to the product attribute generating device 8'.

[0162] The parts list generating means 5 differs from the parts list generating means 5' in generating a parts list by using the representative parts generated by the representative parts generating means 4.

[0163] When the product attribute accumulating device 8' accumulates the attribute values of representative parts, it is different from the product attribute accumulating device 8 in the accumulation method such as obtaining the maximum value of sub-part attribute values and obtaining the representative value of sub-parts for representative parts. .

[0164] What is achieved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com