Nonwoven guide device for a comber

A guide device, comber technology, applied in the direction of combers, textile and papermaking, fiber processing, etc., can solve problems such as adverse effects of combed sliver, damage to the structure of the cotton web, increased overlap and other failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

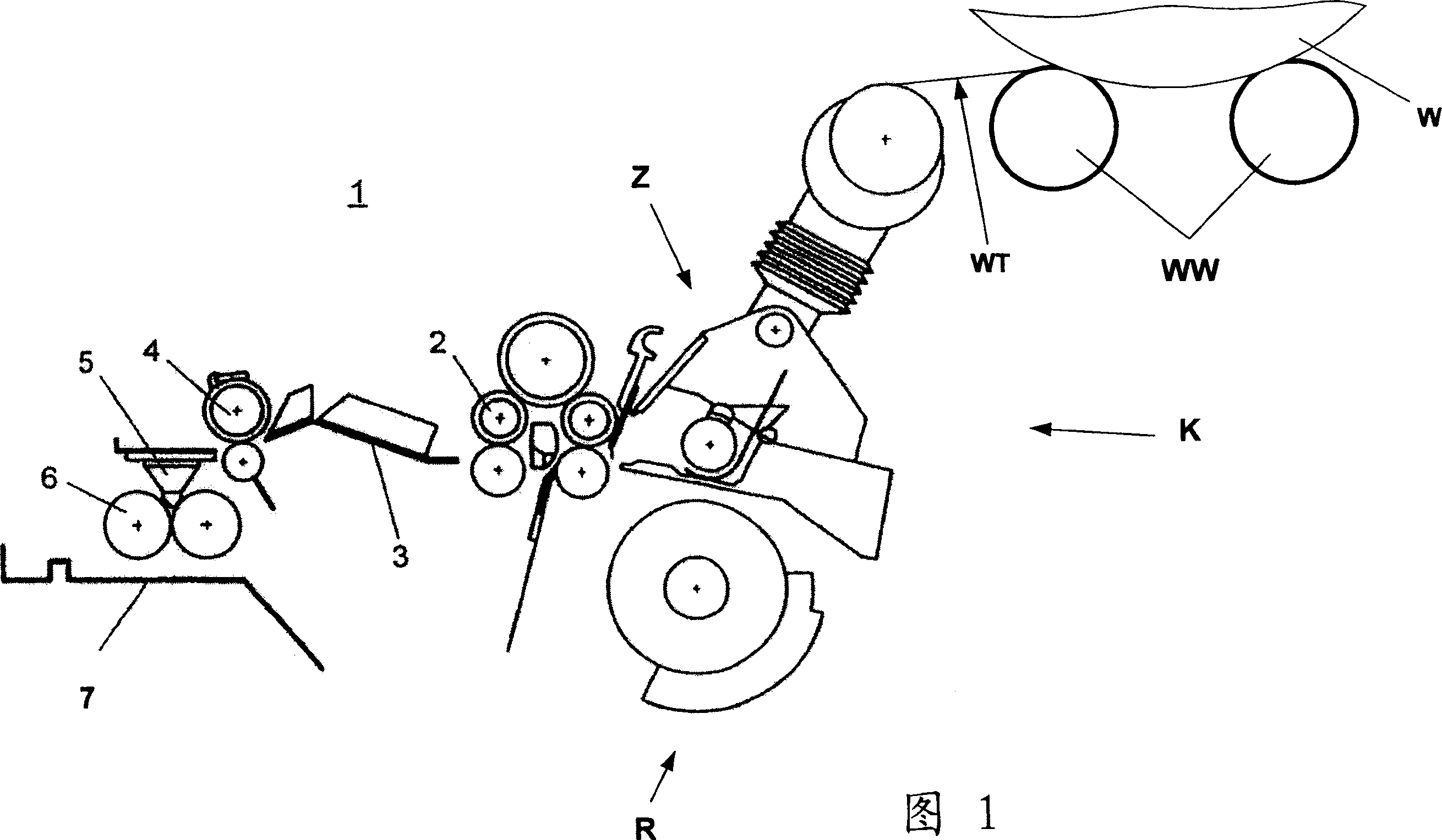

[0022] FIG. 1 schematically shows a combing head KD of a combing machine 1 with a lap roller (WW) on which a filler lap (W) for unwinding is arranged. The fiber raw material is provided to the nipper Z in the form of filler WT, and when the nipper is in the rear closed position, the end of the filler is provided to the circular comb rotatably installed under the nipper for combing.

[0023] In the front position shown in Figure 1, with the nipper Z open, the combed filler ends (also called fiber strands) are supplied to a subsequent pair of detaching rollers 2 for joining to the previously formed web . In the illustrated embodiment, two consecutive teams of separating drafting rollers 2 are shown, in particular the pair of separating rollers directly behind the nipper Z is responsible for the separating and joining operations.

[0024] The former pair of separation rollers 2 are followed by a cotton web guide plate 3, a pair of delivery rollers 4, a funnel 5, calendering roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com