Resilient plate type stereo compact spinning device for spinning machine

A spinning frame and disc-type technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as broken yarn, high production cost, complex structure, etc., to avoid yarn blocking and broken yarn, improve Conveying form and the effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

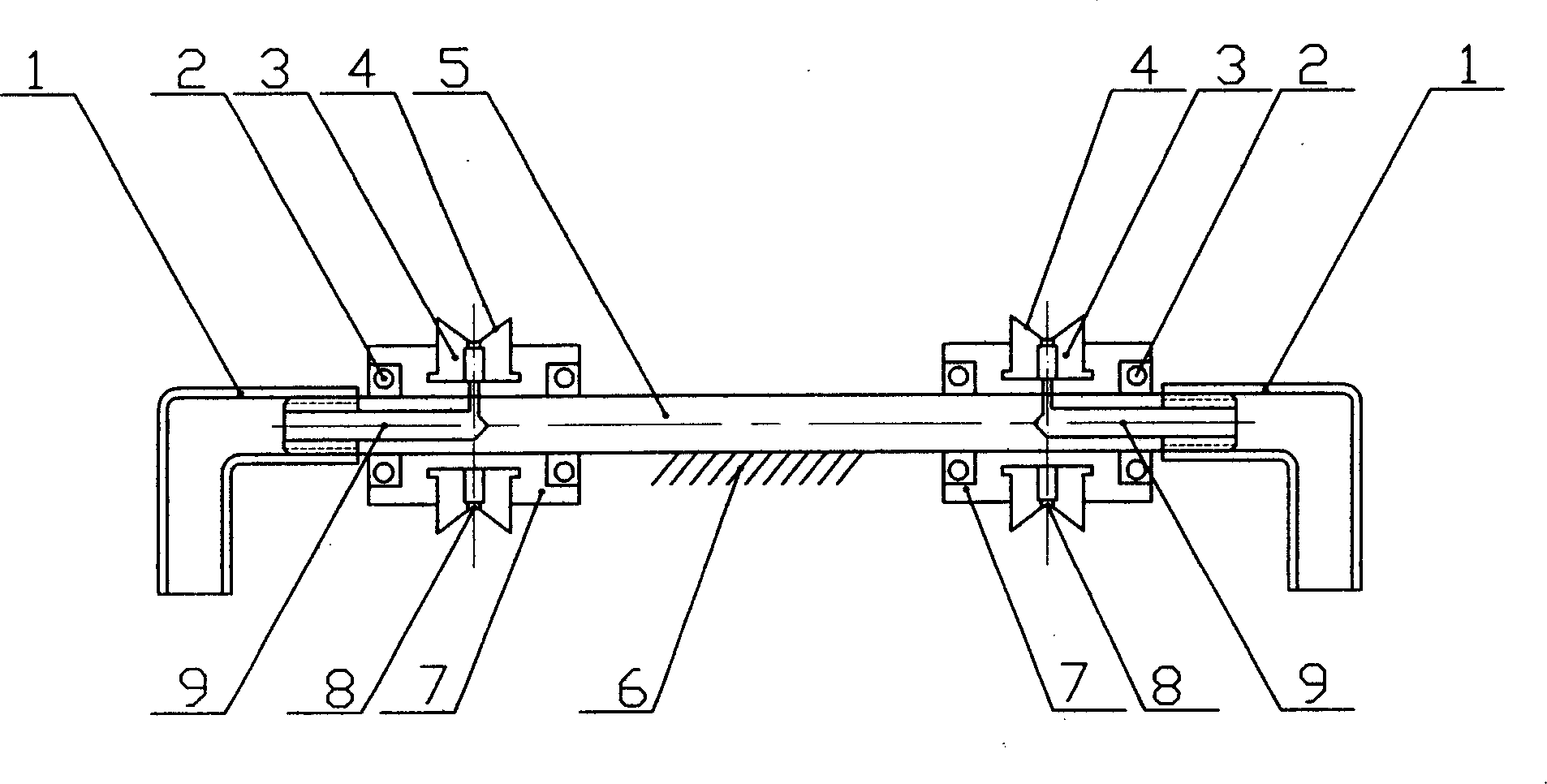

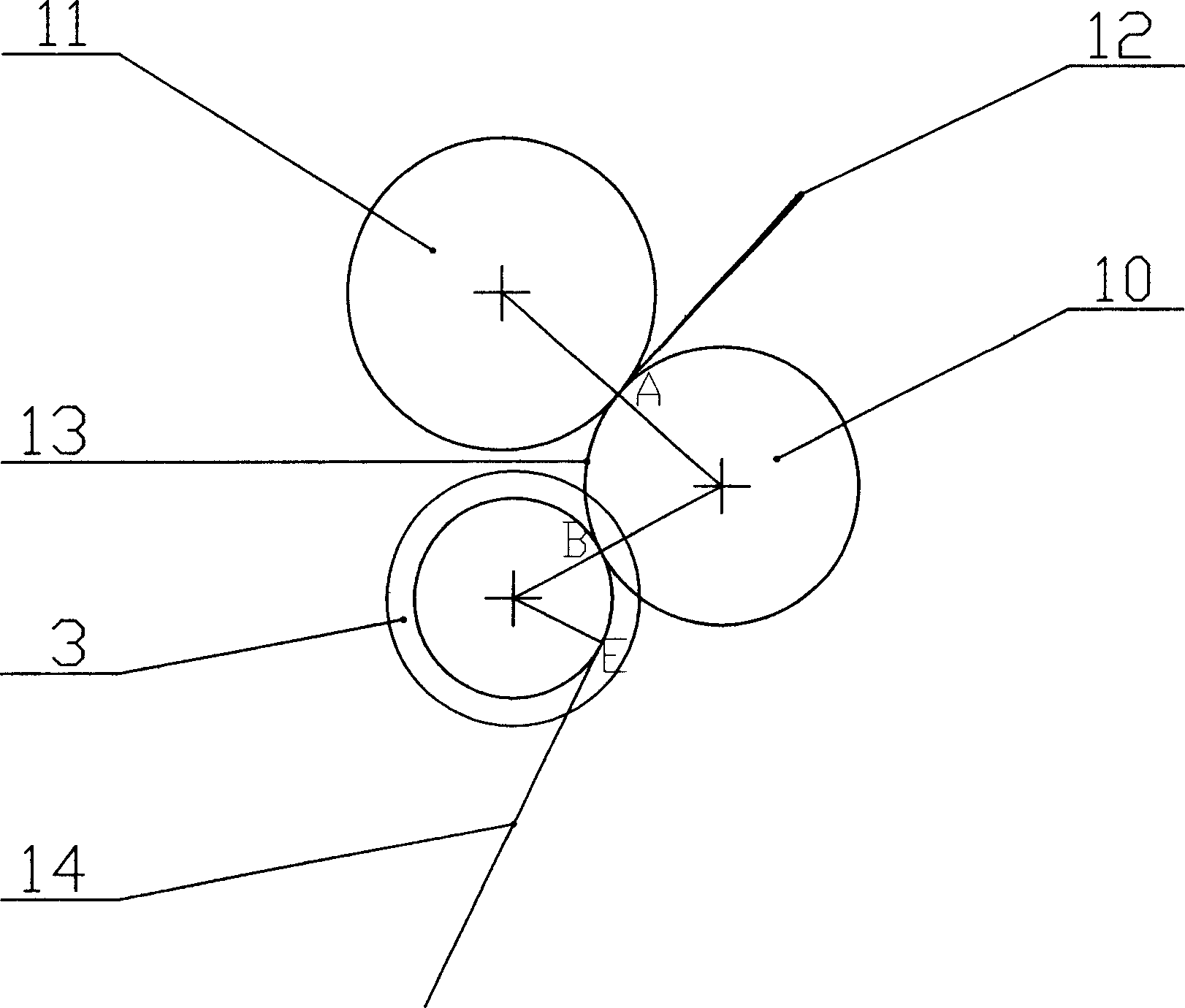

[0015] Such as figure 1 , figure 2 As shown, the negative pressure tube 1 is connected to the central shaft 5, a set of bearings 2 are mounted on the central shaft 5, the yarn guide plate body 7 is mounted on the bearing 2, and the elastic yarn guide plate 3 is mounted on the yarn guide plate body 7. The yarn guide plate 3 is provided with a groove 4, the groove 4 has a number of negative pressure holes 8 at the bottom of the groove, the central shaft 5 is fixed on the spinning frame by the connecting plate 6, and the central shaft 5 is provided with a negative pressure channel 9, which is connected to the negative pressure The pressure hole 8 and the negative pressure pipe 11 constitute a negative pressure system. The yarn guide plate 3 is pressed tightly on the roller 10, the thick sliver 12 passes between the roller 10 and the top roller 11, and is drafted into a thin sliver 13, which is twisted into a thin sliver 13 after passing through the elastic guide plate 3 Yarn 14, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com