Roller type sieving machine with adjustable gap conveniently

A screening machine, a convenient technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of poor stability and accuracy of roller screens, difficulty in maintenance and inconvenient adjustment, etc., to achieve less workload and reduce Accurate effect of workload and gap adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

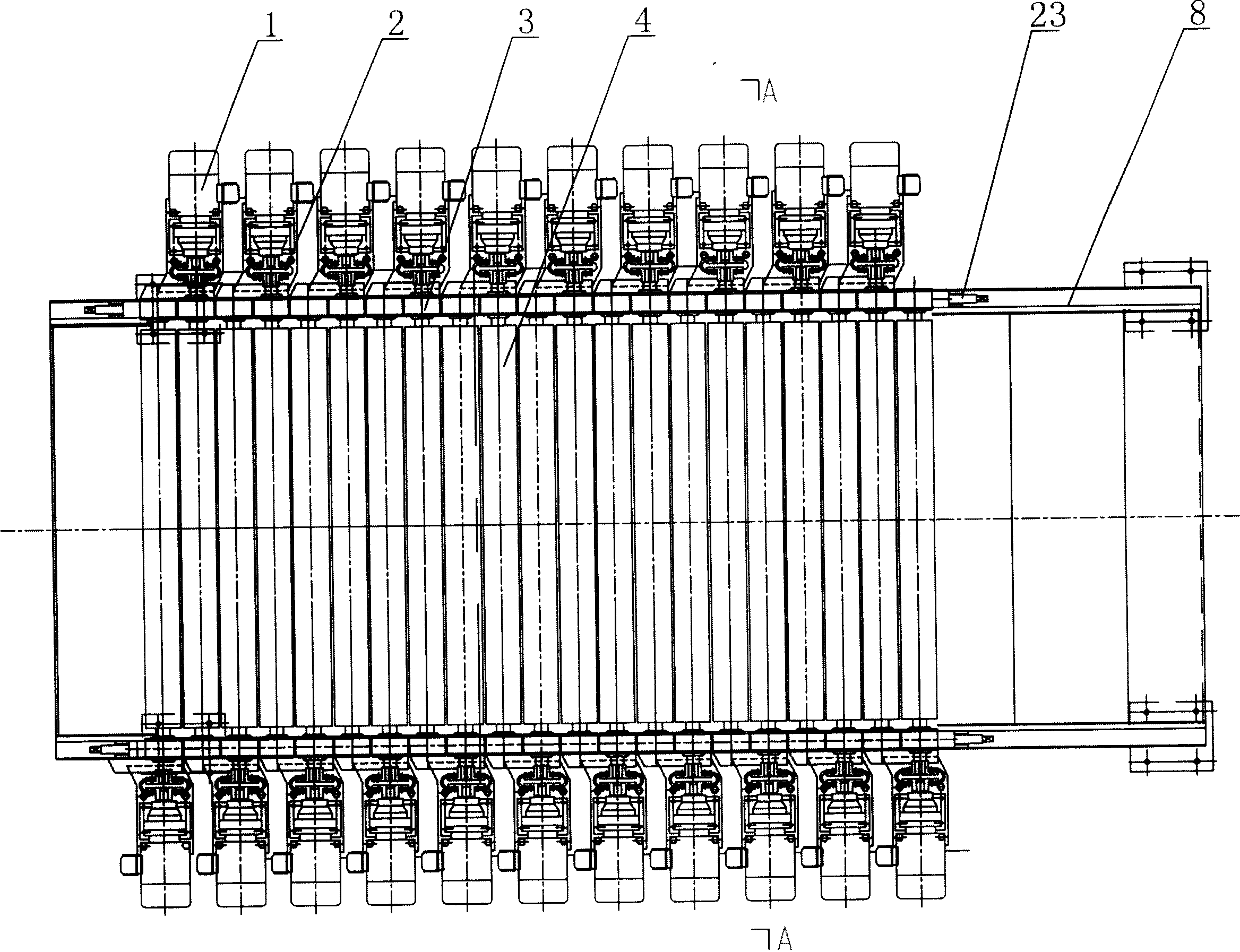

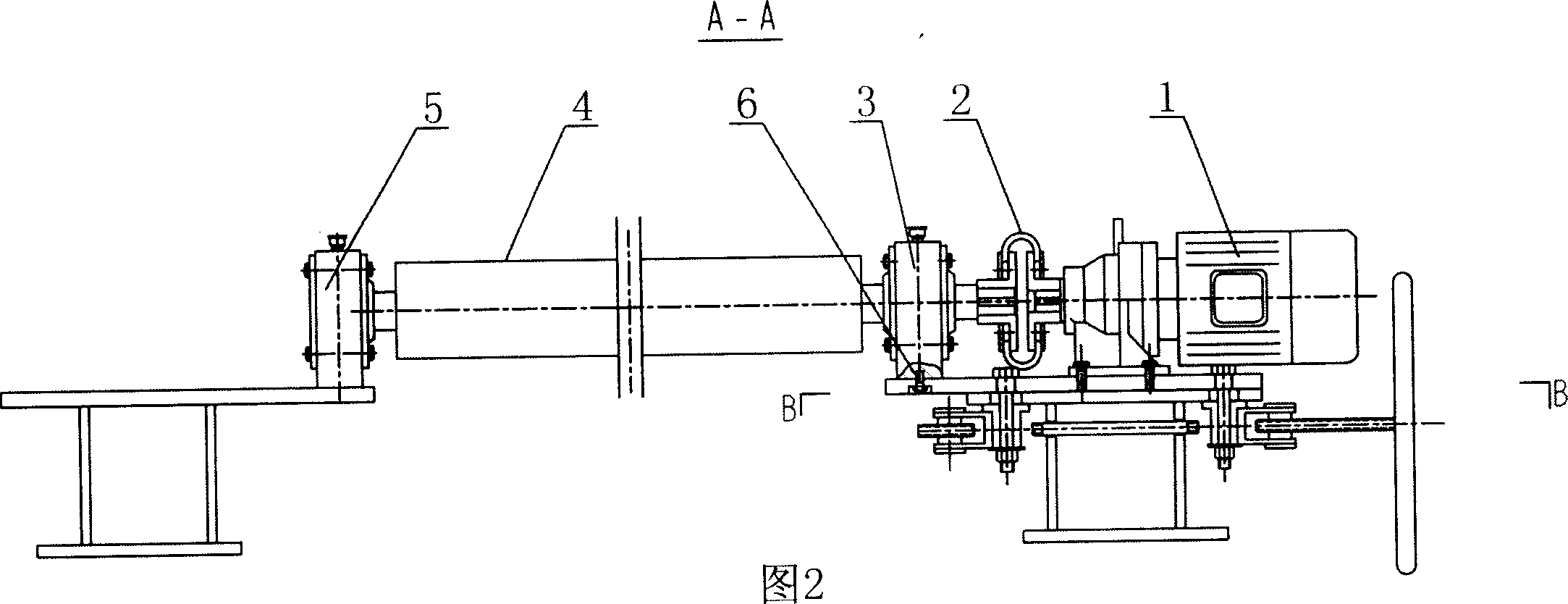

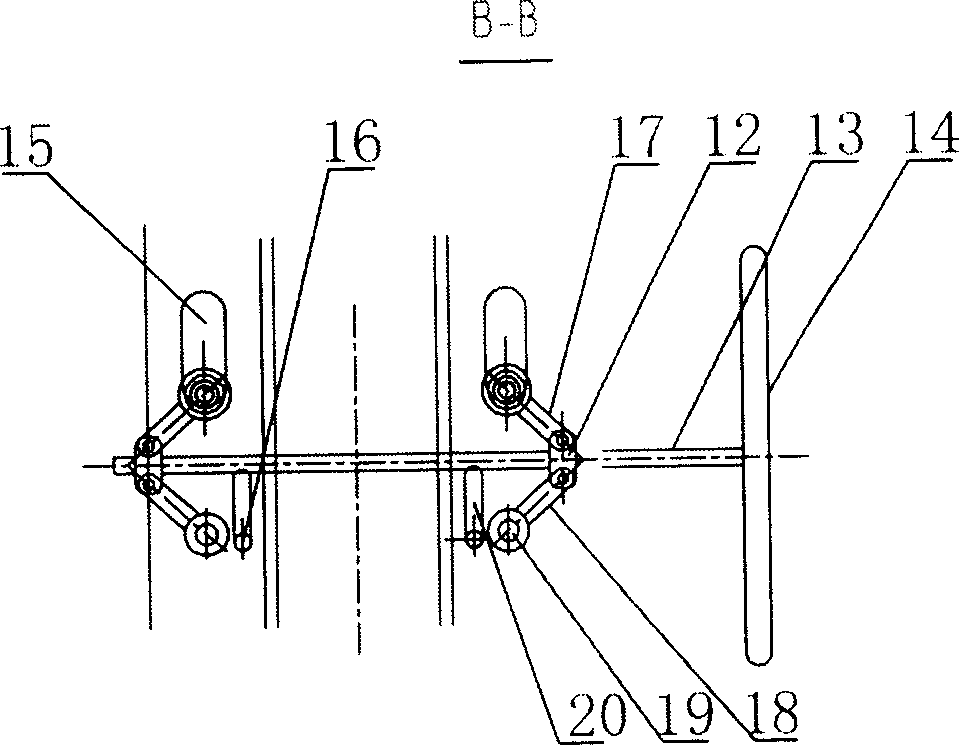

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0018] like figure 1 , shown in Fig. 2, the roller type screening machine that gap can be adjusted conveniently of the present invention, comprises at least two screening rollers 4 that are arranged in parallel, screening roller transmission device 1, shaft coupling 2, active bearing seat 3, passive bearing seat 5, The connecting plate 7 and the machine base 6 are characterized in that the active bearing seat 3 and the transmission device 1 are fixed on the connecting plate 7 through bolts 8, and the connecting plate 7 is connected with the machine base 8 through sliding connecting bolts 9, the described The sliding connecting bolt 9 is covered with a sliding block 10 and a circular sleeve 11. The sliding block 10 is installed in the chute 15 of the machine base 8 and is slidably matched with the machine base 8. The upper surface of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com