Pattern replication with intermediate stamp

A cyclic olefin copolymer, copolymer technology, applied in the process of processing and utilizing such a polymer stamp, a two-step process of making and using such a polymer stamp, the field of polymer stamps for imprinting processes, It can solve the problems of non-reusable, reducing the fidelity of replicas, difficult template release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

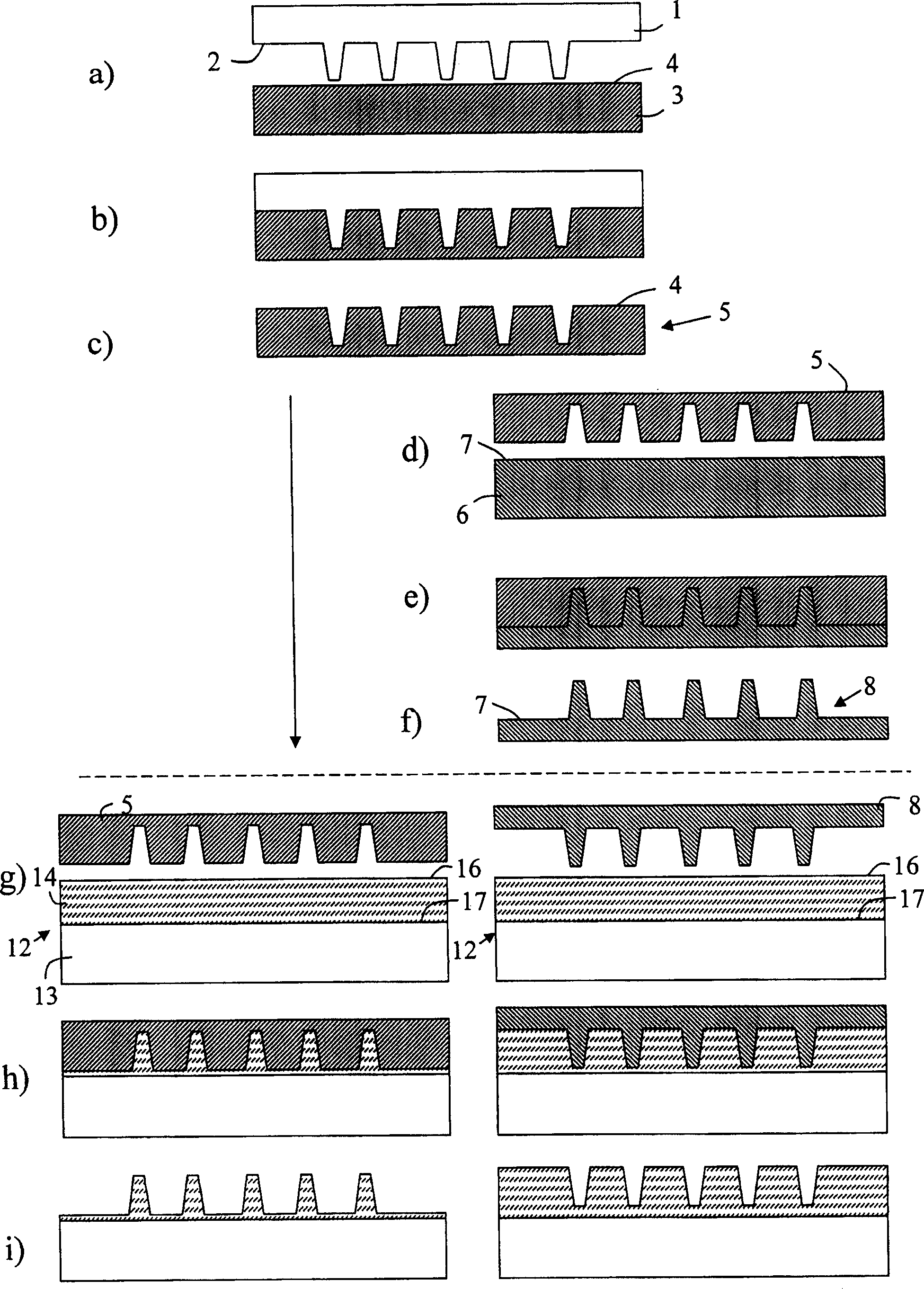

[0122] A nickel template with a line pattern with a line width of 80 nm and a height of 90 nm on the surface was imprinted into Zeonor ZF14 at 150° C. and 50 bar for 3 minutes. The Ni surface is pretreated with a fluorinated SAM anti-stick layer to obtain a low surface tension below 20 mN / m, preferably below 18 mN / m. The Zeonor foil is mechanically removed from the stencil surface without damaging the pattern of the stencil nor the pattern of the replica. Zeonor foil was used as a new template, which was imprinted into a 100 nm-thick SU8 film. The SU8 film was spin-coated onto a 20 nm LOR film previously spin-coated onto a silicon substrate, and neither surface was treated with an additional coating in order to improve the anti-stick properties between the SU8 film and Zeonor foil. Imprinting was carried out at 70° C. and 50 bar for 3 minutes. The SU8 film was exposed to UV light for 4 seconds through an optically clear Zeonor foil and baked for over 2 minutes. During the e...

Embodiment 2

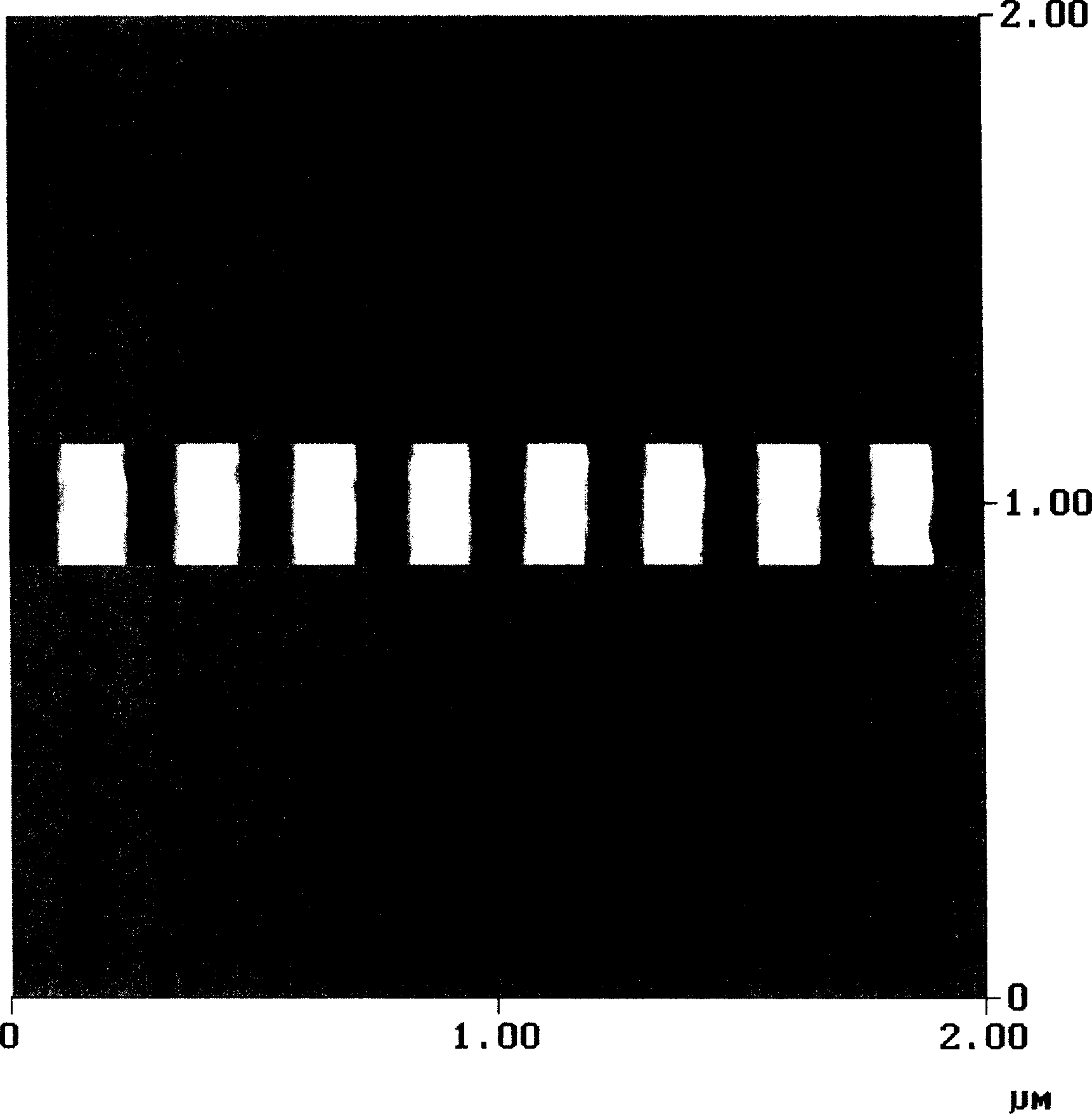

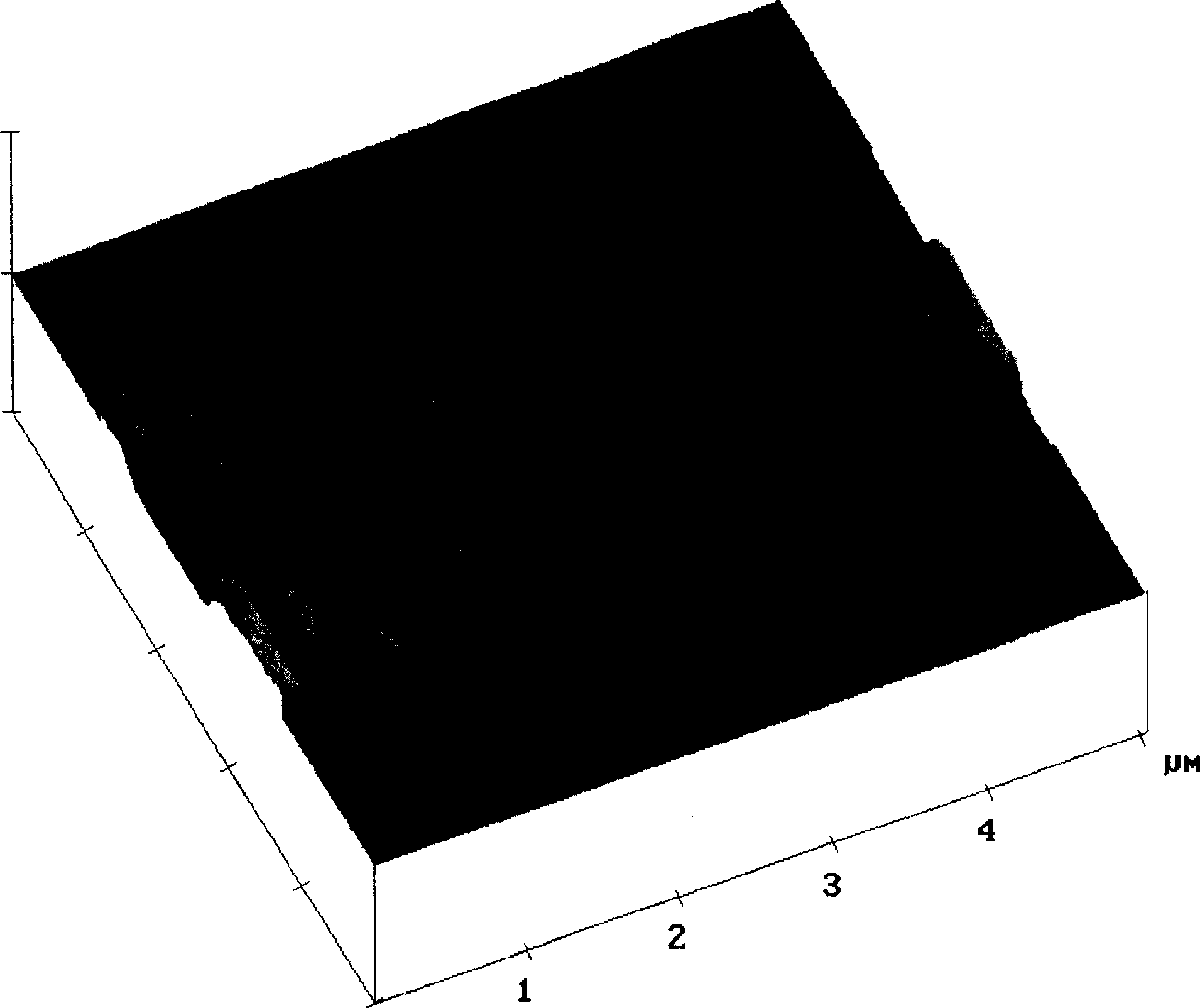

[0124] Using the same method and the same parameters as already described in Example 1, a nickel template (developed by AFM) with a BluRay pattern with a structure height of 100 nm and a width of 150 nm on the surface was imprinted into Zeonor ZF14. Zeonor foil was used as a new template, which was imprinted into a 100 nm-thick SU8 film. Again, the same method and the same parameters as already described in Example 1 are used here. AFM images of imprints obtained in SU8 thin films deposited on silicon wafers in image 3 shown in.

Embodiment 3

[0126] A nickel template with a surface comprising high aspect ratio micron patterns ranging from 1-28 was used. Feature sizes range from 600nm-12μm with a height of 17μm. Before embossing, the surface is covered with a phosphate-based anti-stick film. Nickel templates were imprinted into polycarbonate foil at 190°C and 50 bar for 3 minutes. To improve the anti-stick properties between the Ni template and the polycarbonate film, the surface of the polycarbonate foil was treated with an additional coating. The release temperature was 130°C at which the polycarbonate foil could be mechanically removed from the nickel surface without damaging the pattern of the template nor the pattern of the replica. Polycarbonate foil was used as a new template to imprint the Topes foil. Imprinting was carried out at a temperature of 120° C. and a pressure of 50 bar for 3 minutes. None of the surfaces were treated with an additional coating to improve the anti-stick properties between the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com