Cutting mechanism of cloth-stentering machine

A cloth stretching machine and cutting head technology, which is applied in the direction of fabric elongation, fabric surface trimming, washing device, etc., can solve problems such as inability to guarantee, sliding fabric 12 is not smooth, and affects the cloth releasing mechanism, etc., to achieve guarantee normalizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Through the applicant's detailed description in combination with the embodiments, it will be more helpful to understand the present invention and make the technical effects brought by the present invention clearer, but the embodiments should not be regarded as limiting the present invention.

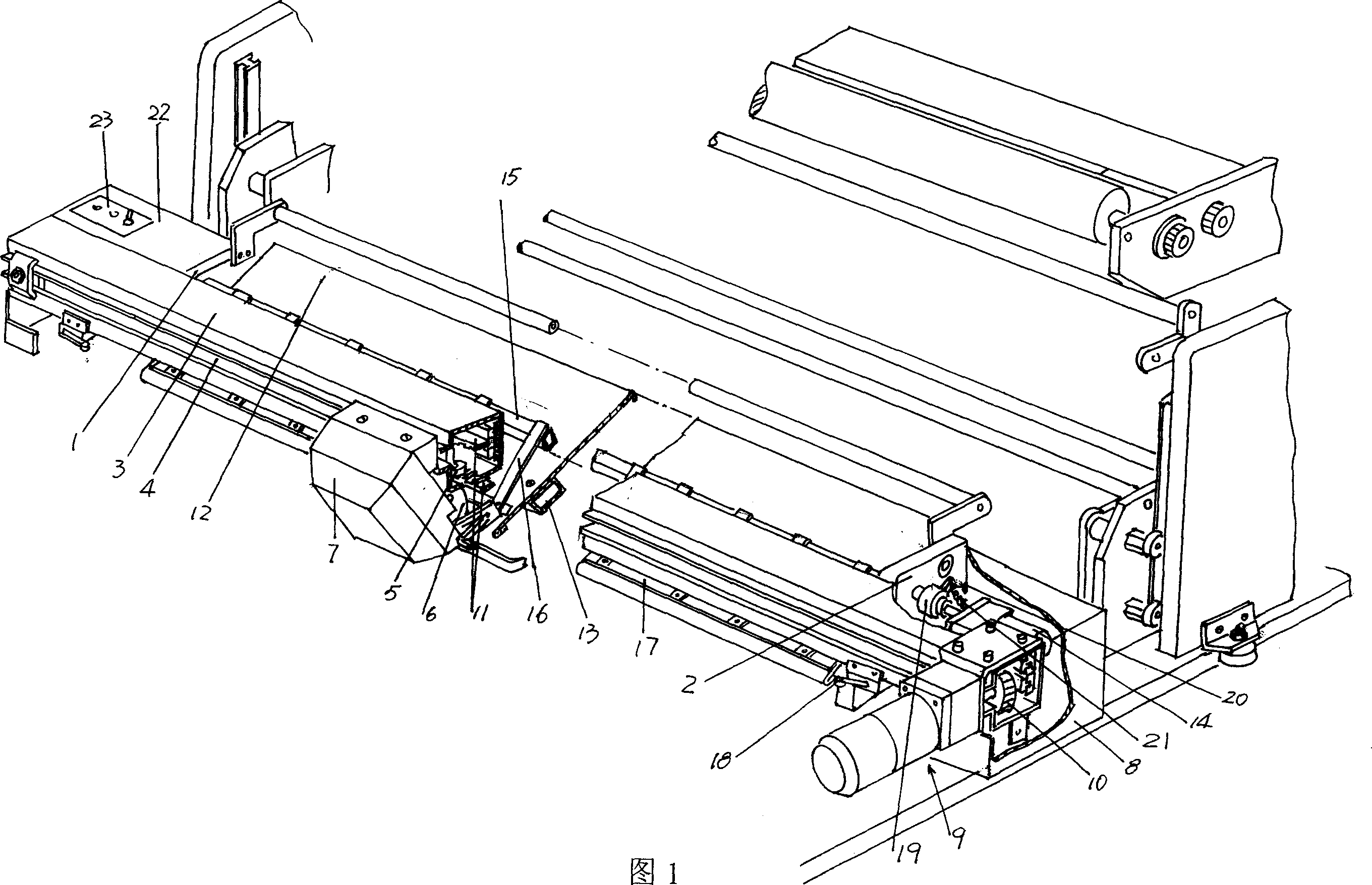

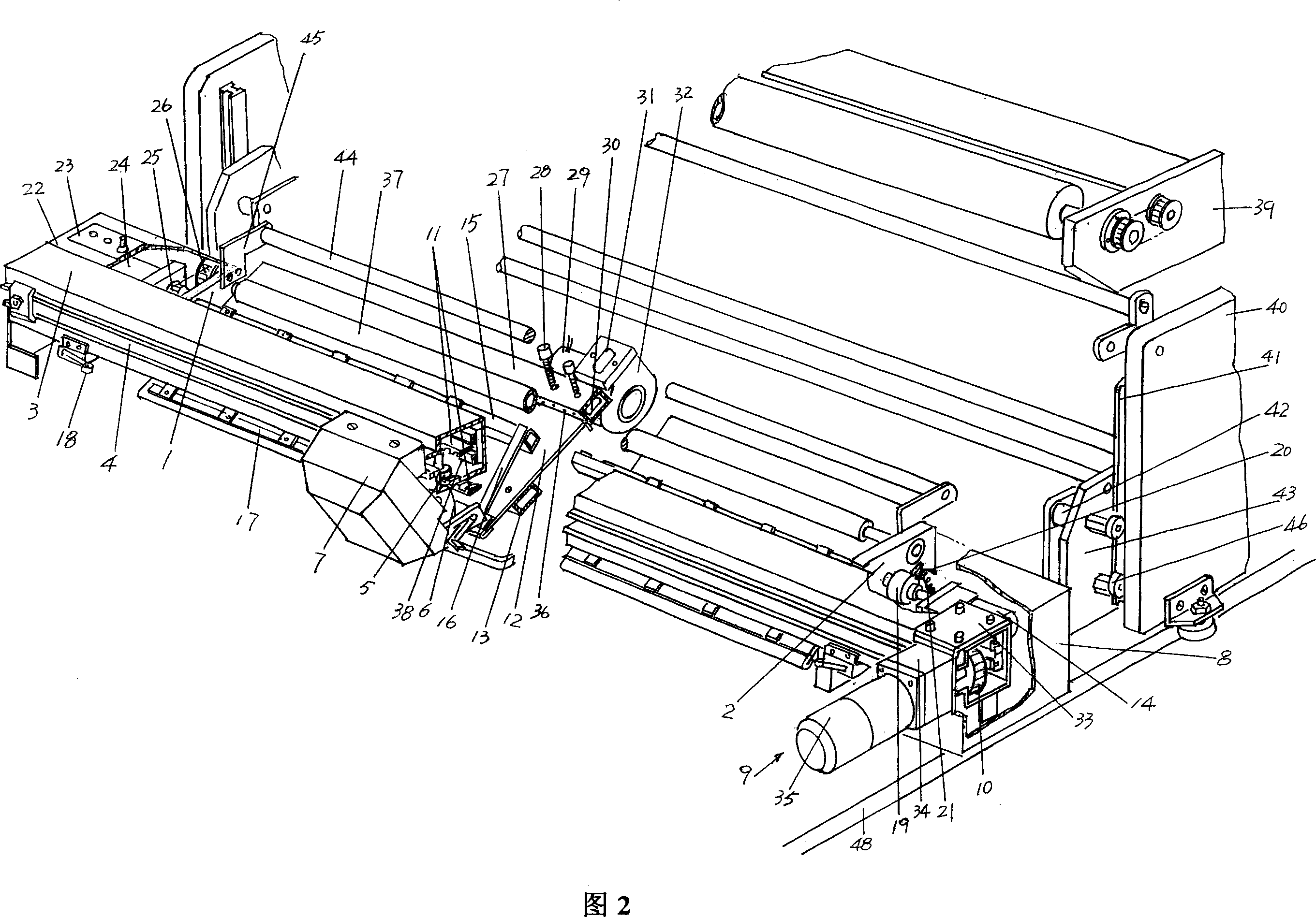

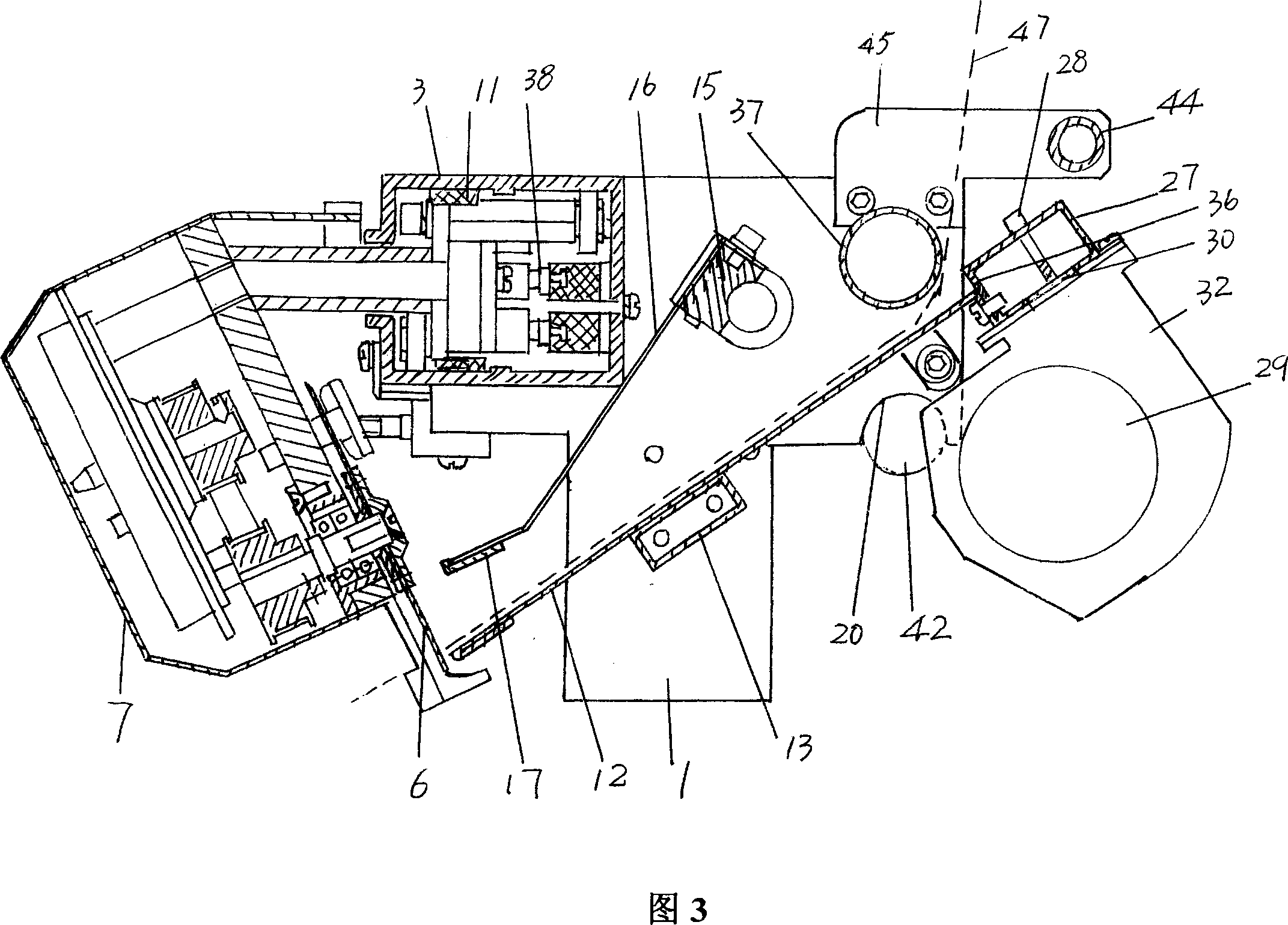

[0019] In Fig. 2 and Fig. 3, a pair of left and right wallboards 1 and 2 of the cutting mechanism of the spreading machine are shown, and the two ends of a guide beam 3 with a rectangular cross-sectional shape are fixed on the left and right wallboards 1 , 2, and the two ends of the guide beam 3 also extend to the left and right casings 22, 8 places, and the two ends of at least one sliding cloth board hosting 13 are welded to the left and right wall panels 1, 2 fastened or riveted or otherwise fixed such as by screws. Taking the position state shown in Figure 2 as an example, a cutting head guide rail 4 is formed on the front side of the guide beam 3. For the cutting head guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com