Multilayer enclosing-rock cement-grouting consolidation ring tunnel bearing structure and its construction method

A technology of bearing structures and consolidation rings, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficulty in adapting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

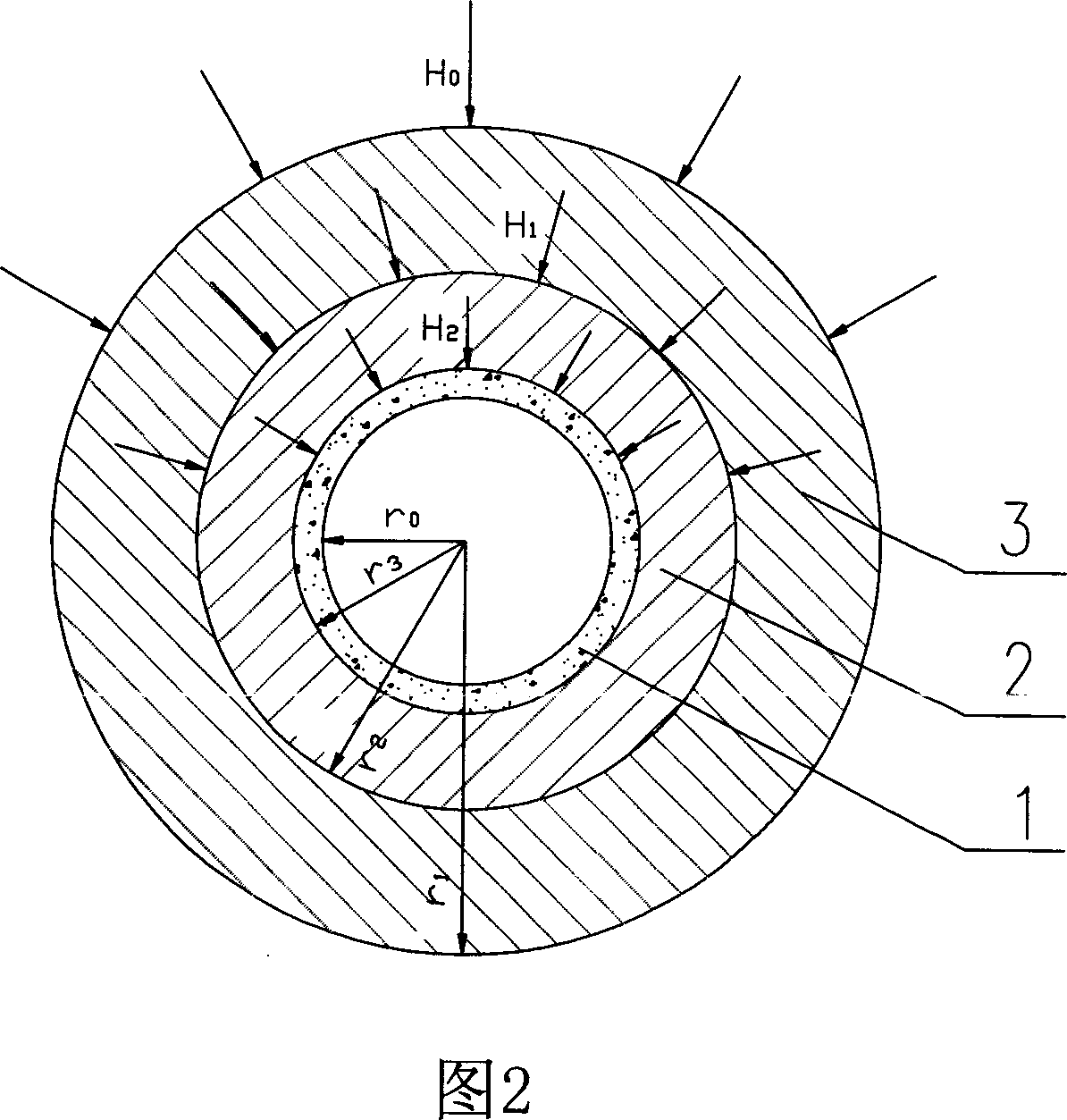

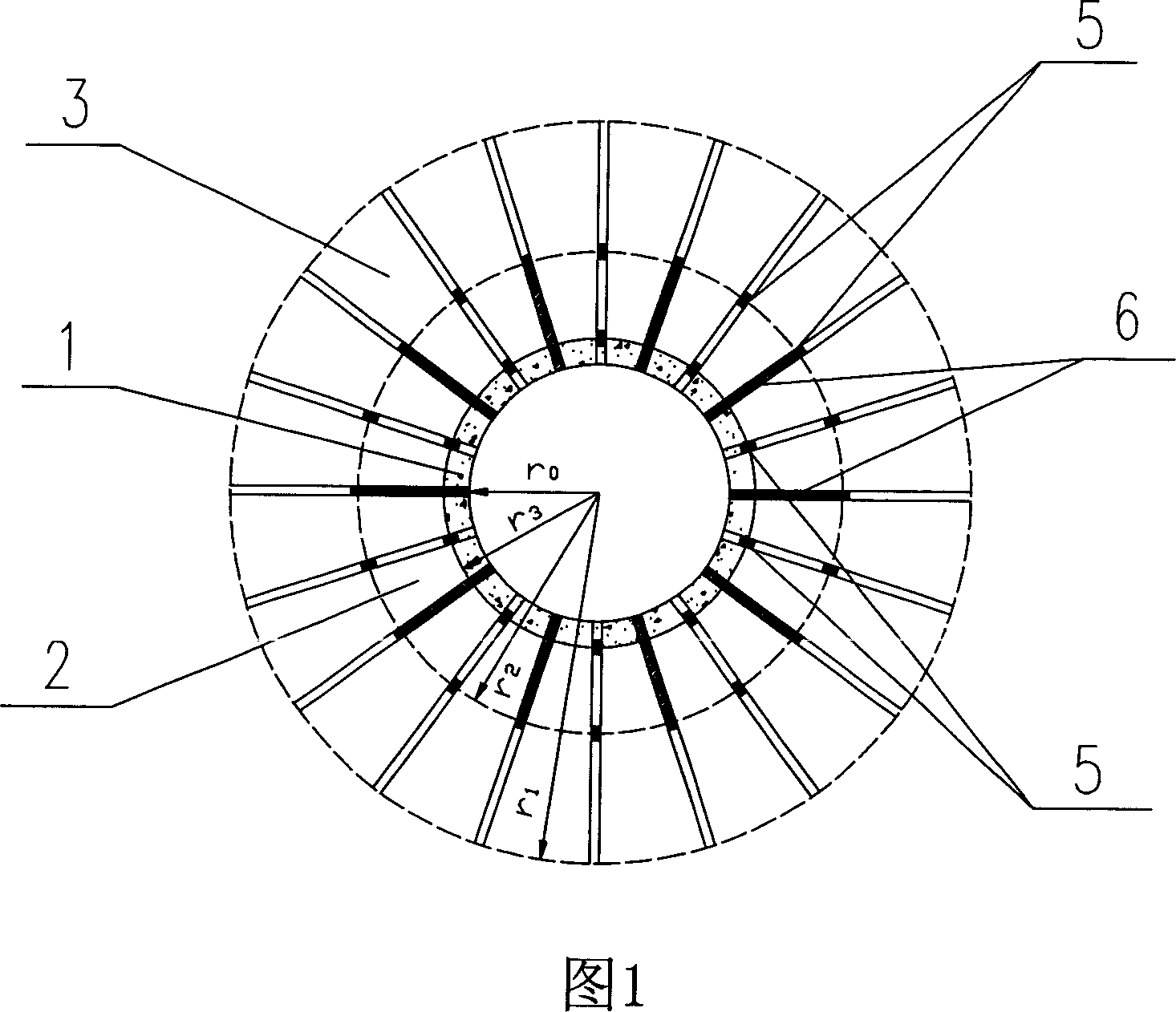

[0017] Embodiment 1, as figure 1 , figure 2 As shown, this example is a circular tunnel 1 and a second-layer surrounding rock consolidation grouting circle, and the grouting of each consolidation grouting borehole is divided into two sections. The consolidation grouting circle of surrounding rock 3 in the outer layer of the tunnel is relatively dense, has a small permeability coefficient, and correspondingly bears a large external water seepage pressure, while the consolidation grouting circle of inner surrounding rock 2 is relatively sparse, has a large permeability coefficient, and correspondingly bears a small external water seepage pressure . The grouting holes of the inner layer grouting ring are radially spaced one or two holes away from the consolidation grouting, and directly use high-grade cement mortar to seal the holes 6 . The density of the consolidation grouting hole in this example is about 1.0×1.0m, the grouting pressure used for the consolidation grouting of...

Embodiment 2

[0030] Embodiment 2, as figure 1 , figure 2 As shown, this example is also the circular tunnel 1 and the second layer of consolidation grouting circle. Its basic structure is the same as the previous example, the difference is that the density of the consolidation grouting holes in this example is about 2.0×2.0m, the grouting pressure used for the consolidation grouting of the outer surrounding rock 3 is about 2 times the external water pressure, and the type of grout is Finely ground cement, the particle specific surface area of the cement slurry is 10000cm 2 / g; the grouting pressure used for the consolidation grouting of the inner surrounding rock is about 1.5 times the external water pressure, the type of grout is ordinary cement, and the particle specific surface area of the cement grout is 4500cm 2 / g.

[0031] The construction method of the present embodiment comprises the following steps:

[0032] 1) First, according to the engineering requirements of the tunn...

Embodiment 3

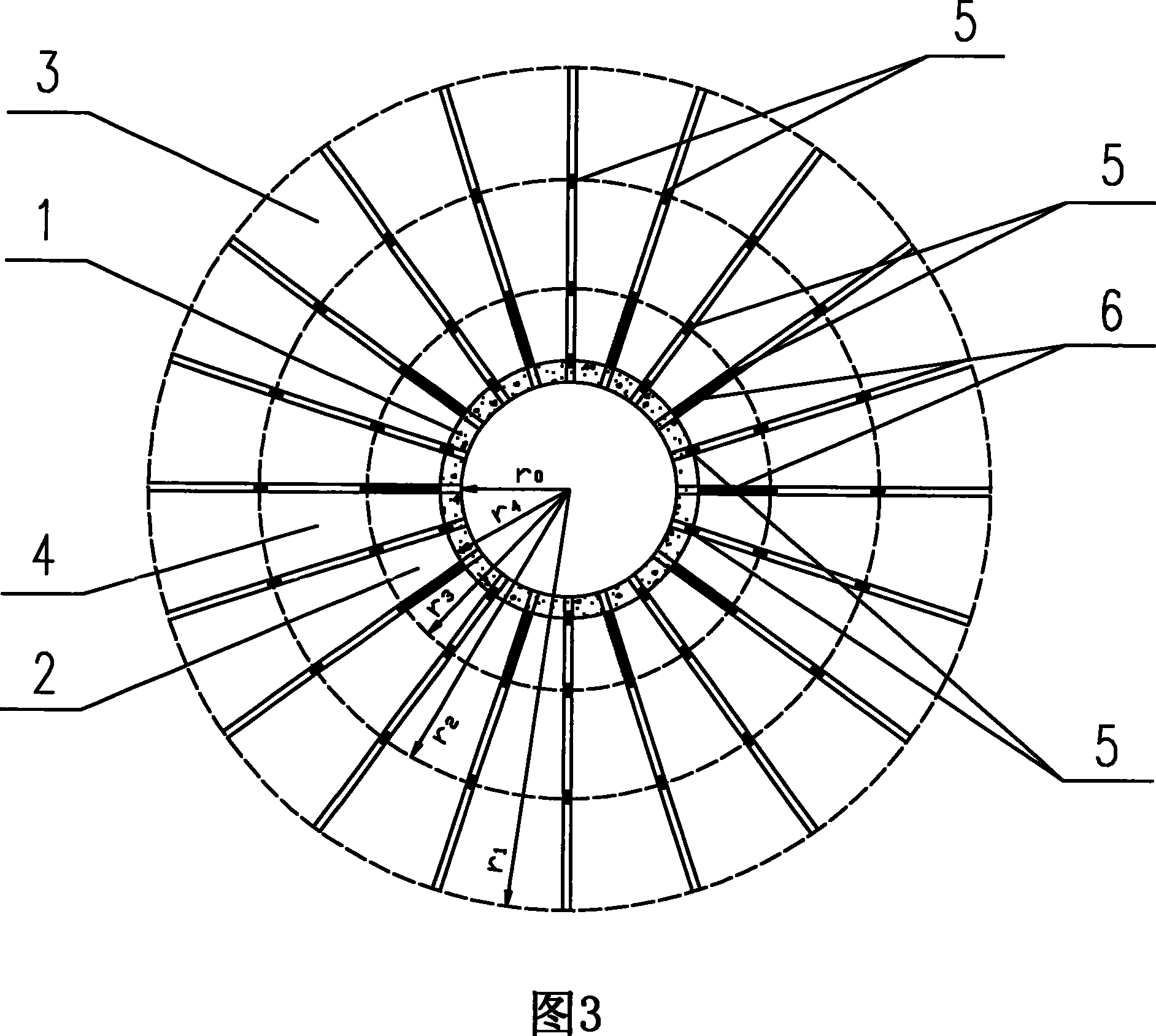

[0034] Embodiment 3, as image 3 As shown in the figure, this example is a circular tunnel 1 and a three-layer surrounding rock consolidation grouting circle. The basic structure is the same as the above example, the difference is that the surrounding rock consolidation grouting circle in this example is three-layered, and the grouting section process of each consolidation grouting hole is increased to three stages, and the density of the consolidation grouting hole is about 1.5×1.5m, the grouting pressure used for the consolidation grouting of the outer surrounding rock 3 is about 1.8 times the external water pressure, and the type of grout is epoxy resin, a chemical grouting material; the grouting pressure used for the consolidation grouting of the intermediate surrounding rock 4 is about 1.5 times the external water pressure, the type of slurry is ground cement, and its particle specific surface area is about 7000cm 2 / g; the grouting pressure used for the consolidation gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com