Damping device of elevator

A vibration damping device and elevator technology, which is applied to elevators in buildings, transportation and packaging, elevators, etc., can solve the problems of reduced vibration damping efficiency in the frequency band of vibration damping, affecting smooth action, and device deterioration, etc., and achieve improvement. The effect of riding feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

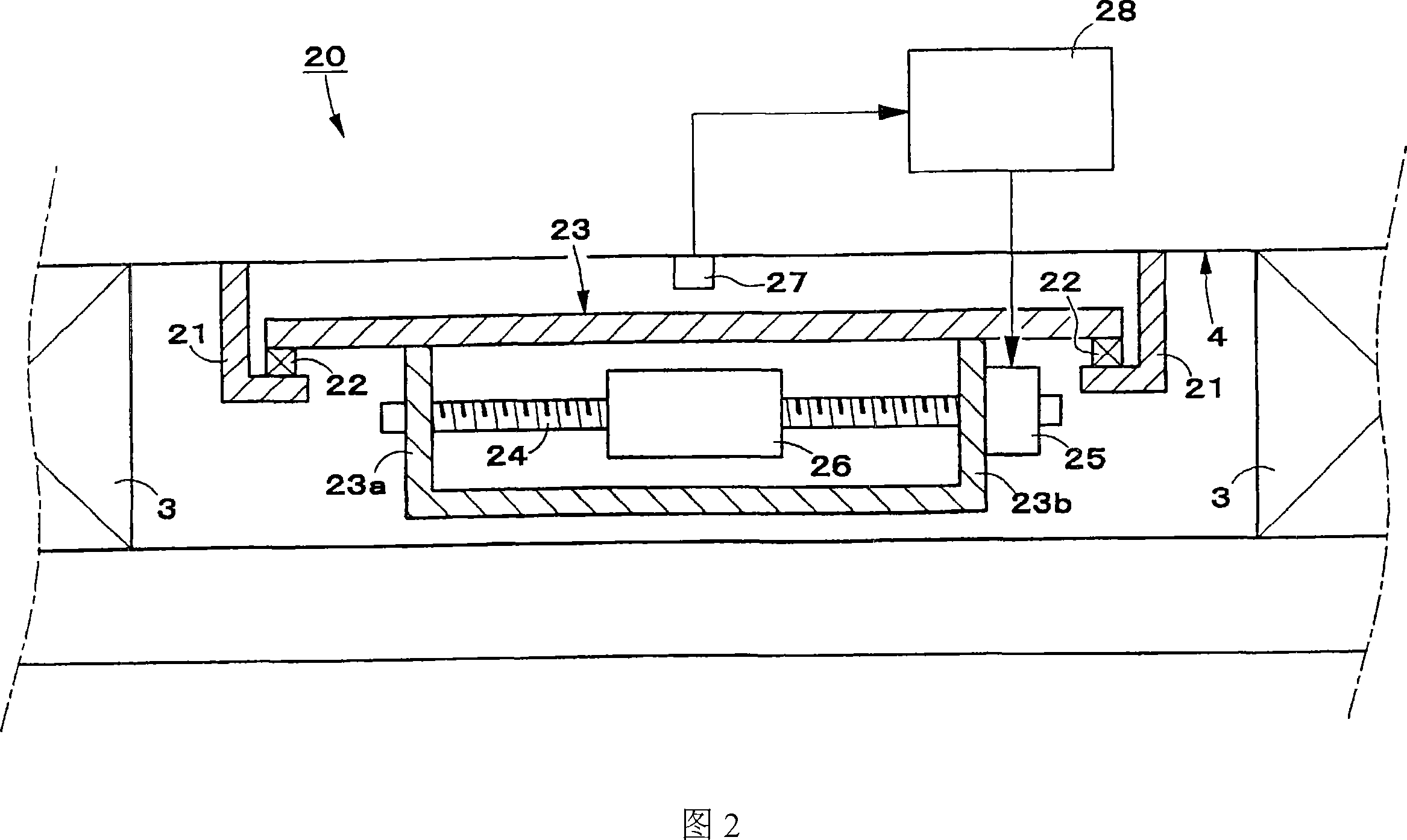

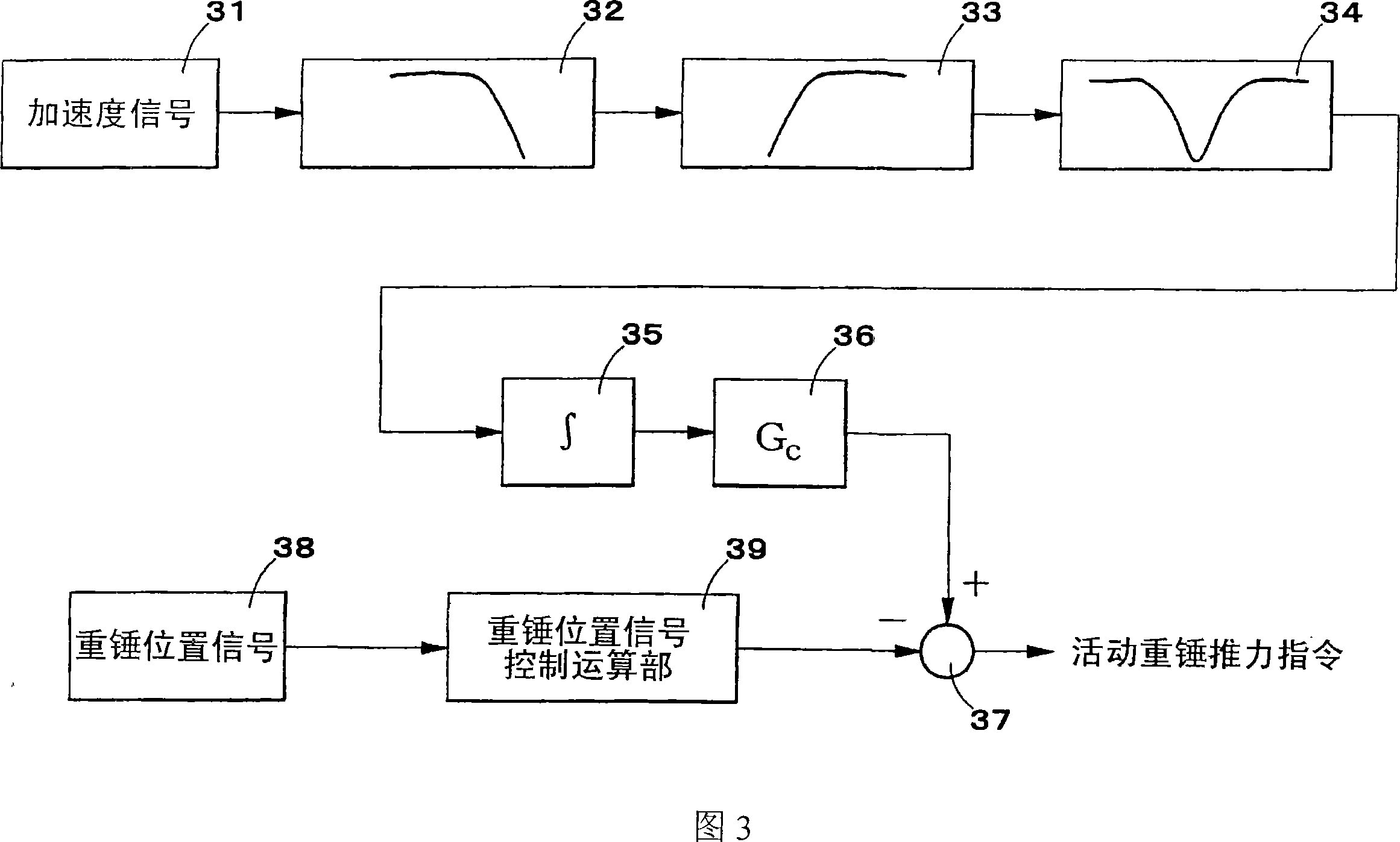

[0103] An embodiment of the elevator vibration damping device of the present invention will be described in detail below with reference to FIGS. 1 to 6 . In addition, in the following description, the same reference numerals are often used for the same parts to omit repeated descriptions.

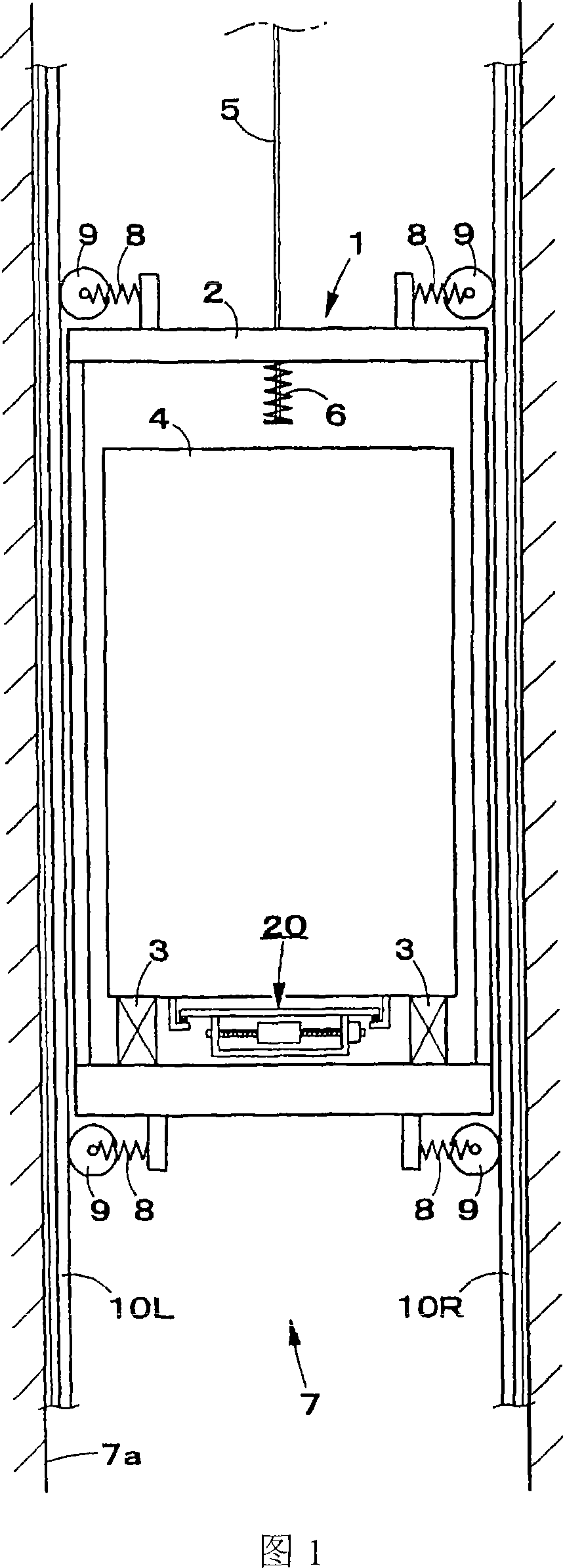

[0104] First, with reference to Fig. 1, the structure of the elevator to which the vibration damping device of the first embodiment is applied is briefly described. At the same time, the main cable 5 hanging down from the unshown winch is connected to the car frame 3 through the vibration insulator 6 and the car 1 is raised and lowered inside the hoistway 7.

[0105] And, the guide rollers 9 supported on the upper and lower corners of the car frame 2 by the vibration insulators (first vibration insulators) 8 are installed on the wall surface 7a of the hoistway 7 and extend in the vertical direction. Rotate on the guide rails 10L and 10R to guide the passenger car 1 to go up and down.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com