Technique for producing composite material

A composite material and process technology, applied in the field of composite material preparation, can solve the problems of insufficient strength of connectors, variable strength properties, difficult process stability, etc., and achieve the effect of satisfying relative magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

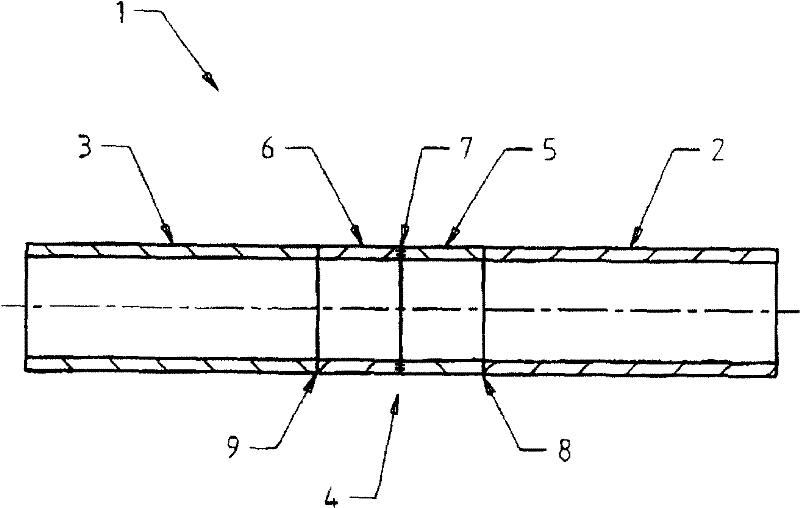

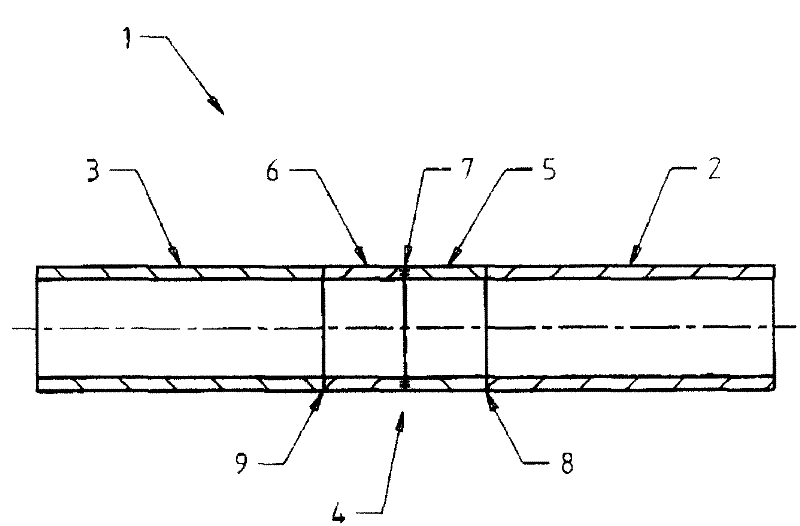

[0028] A tubular composite material 1 was fabricated using Cu-Cr-Zr / 316L (austenitic steel). This composite material is used as a heat exchanger in a fusion reactor splitter.

[0029] To achieve this purpose, the plate made of Cu-Cr-Zr in the solution annealed and quenched state is connected with the plate made of 316L by explosive welding. The surface area of each of the two plates is 500×500mm 2 , The respective thickness is 15mm. For explosive welding, Cu-Cr-Zr sheets are used as "ingot shells". For this purpose, an explosive charge is placed on top of the Cu-Cr-Zr sheet and ignited, resulting in the connection zone 7 .

[0030] After welding, the composite panels are ultrasonically inspected. Connected and unconnected regions can be localized by this approach. A core-shaped intermediate piece 4 is then cut from the joined area of the sheet by means of water jet cutting, wherein the axis of the core is perpendicular to the explosion-welded joining surface 7 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com