Long travel high capacity friction draft gear assembly

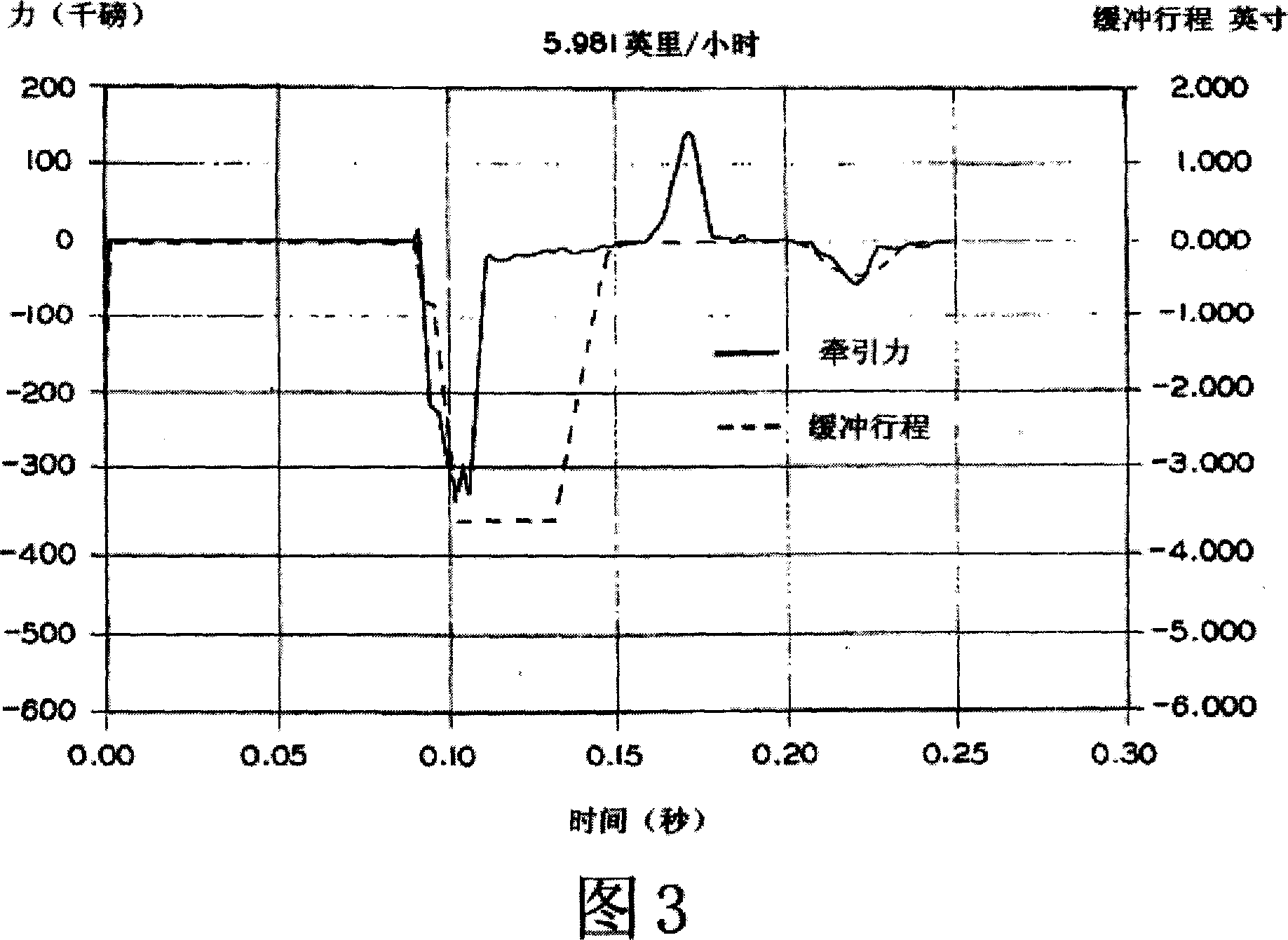

A technology of friction clutch and buffer device, which is applied in the direction of traction device, transportation and packaging, railway car body parts, etc., and can solve the problem that the buffer stroke is only 3.25 inches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

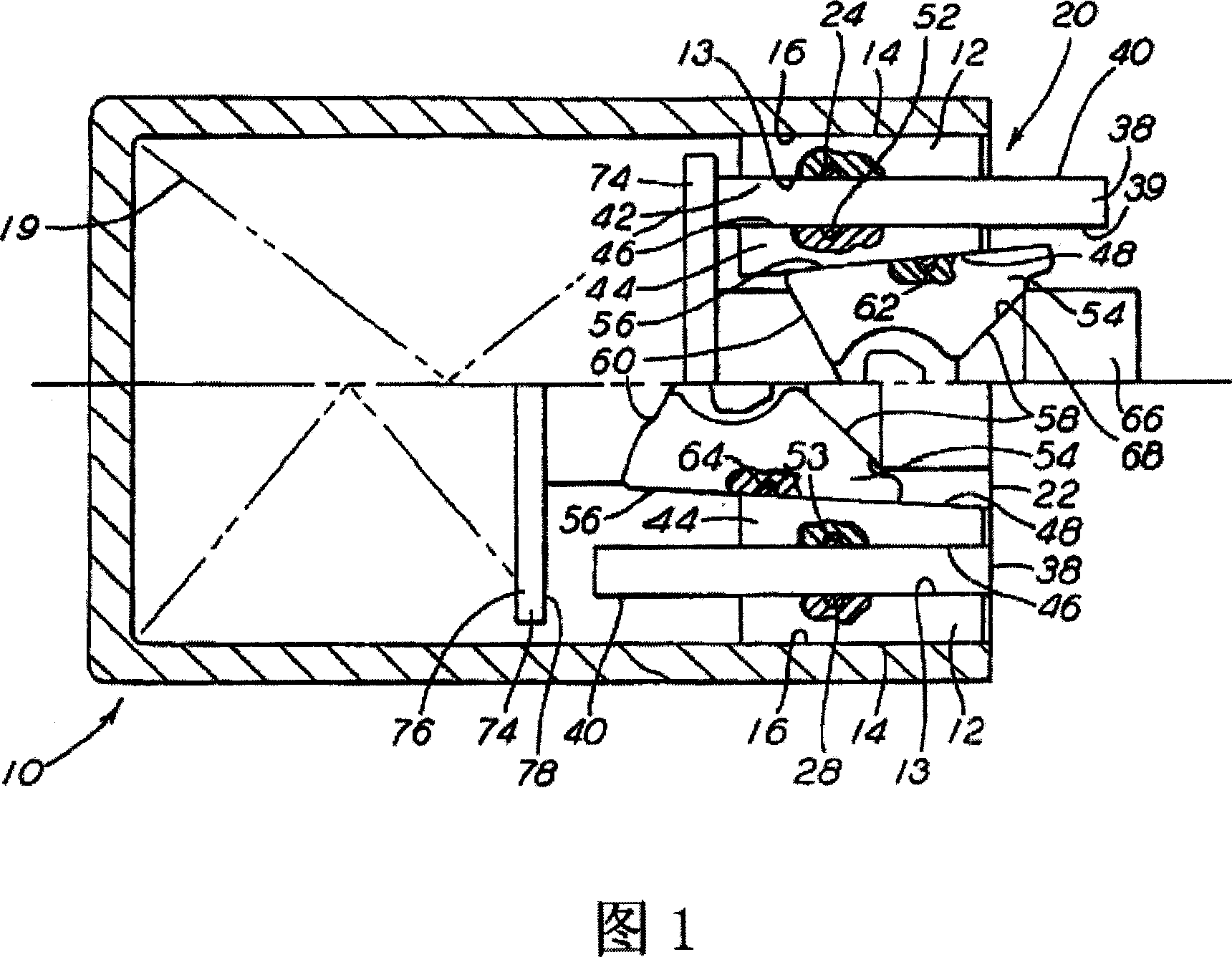

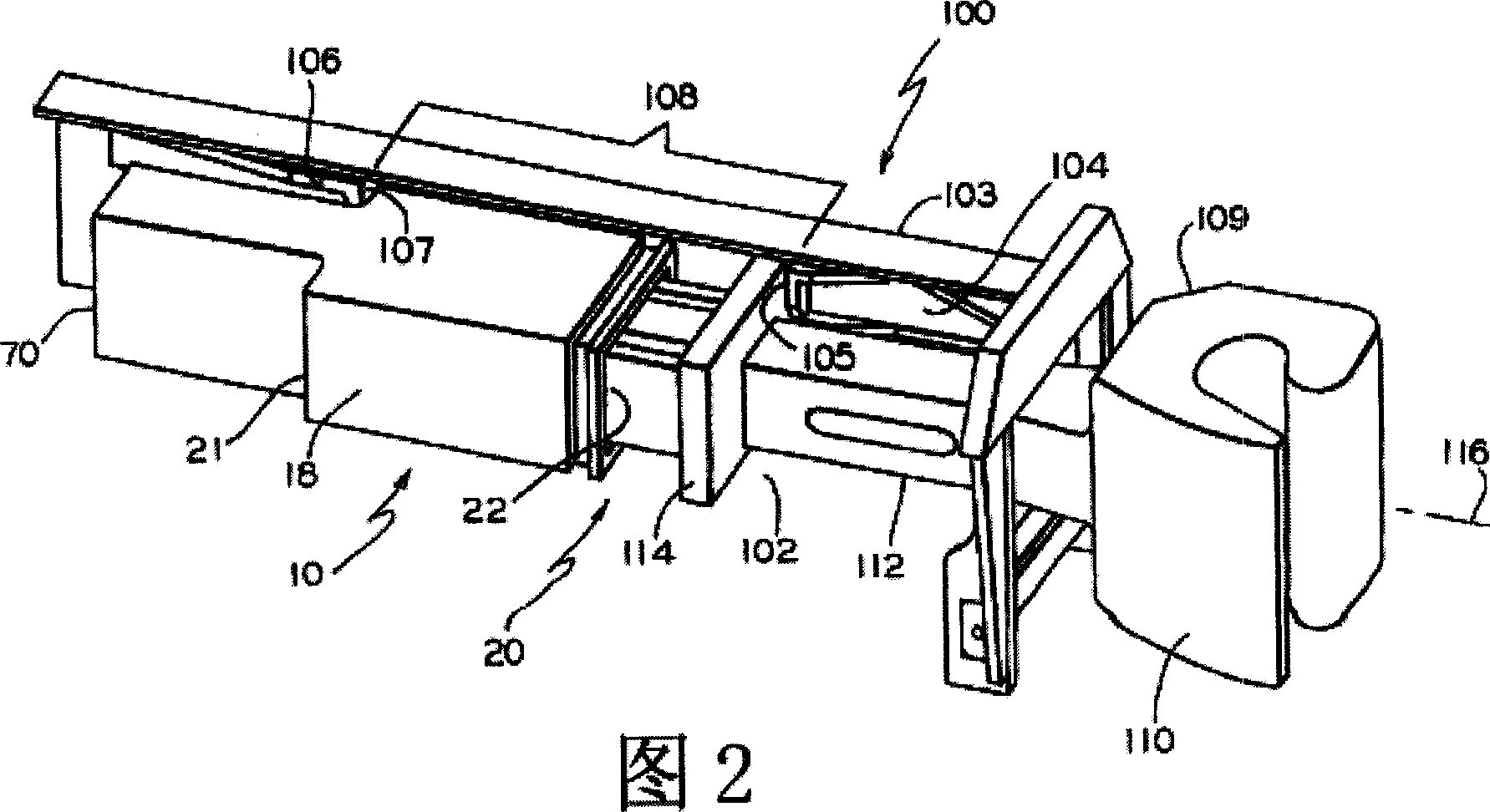

[0024] Description will now be made with reference to the accompanying drawings. As shown in FIG. 1, an improved friction clutch device 20 is used to absorb heat energy in a friction clutch type damper device 10, which is used in a railway locomotive (not shown). As shown in the prior art, this heat energy is generated during the assembly process of the railway vehicle or during the movement of the railway vehicle on the rails.

[0025] The friction clutch device 20 includes a pair of static outer members 12 each having an inner surface 13 and an outer surface 14 . The outer surface 14 engages its diametrically opposite inner surface 16 of the bumper housing 18 near the open end 22 .

[0026] The friction clutch device 20 further includes a pair of moving members 38, each of which has at least a predetermined portion of an outer surface 40 frictionally engaged with the inner surface 13 of its respective outer static member 12 to absorb The first part of the heat. The moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com