Dip angle type rotary seat

A technology of slewing seat and inclination angle, which is applied in the field of slewing seat, can solve the problems of restricting the function and application occasions of ordinary double-head pipe bending machines, and can not complete the three-dimensional three-dimensional bending of pipe fittings to be processed at one time, so as to expand the function and use range and Occasion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

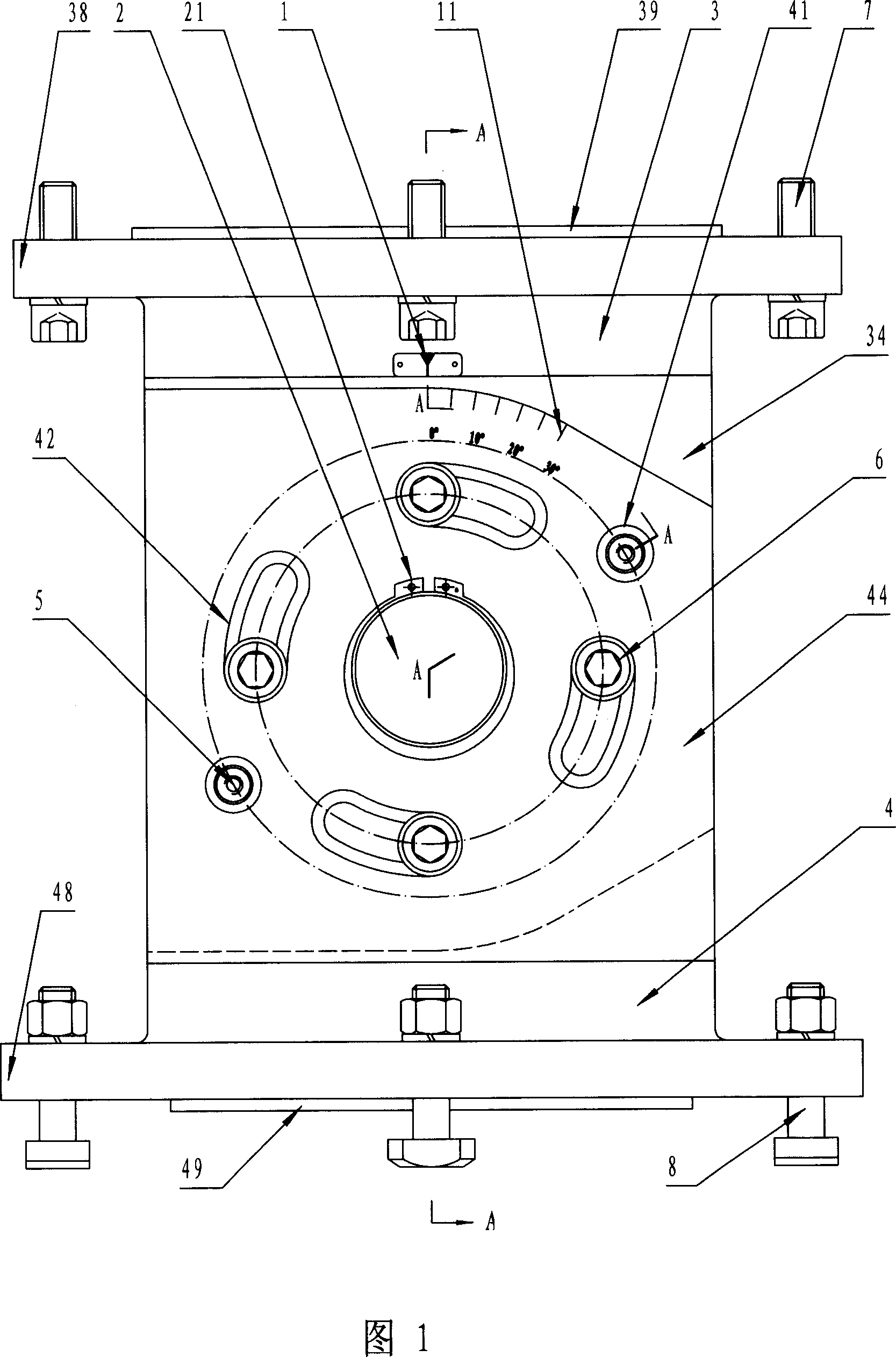

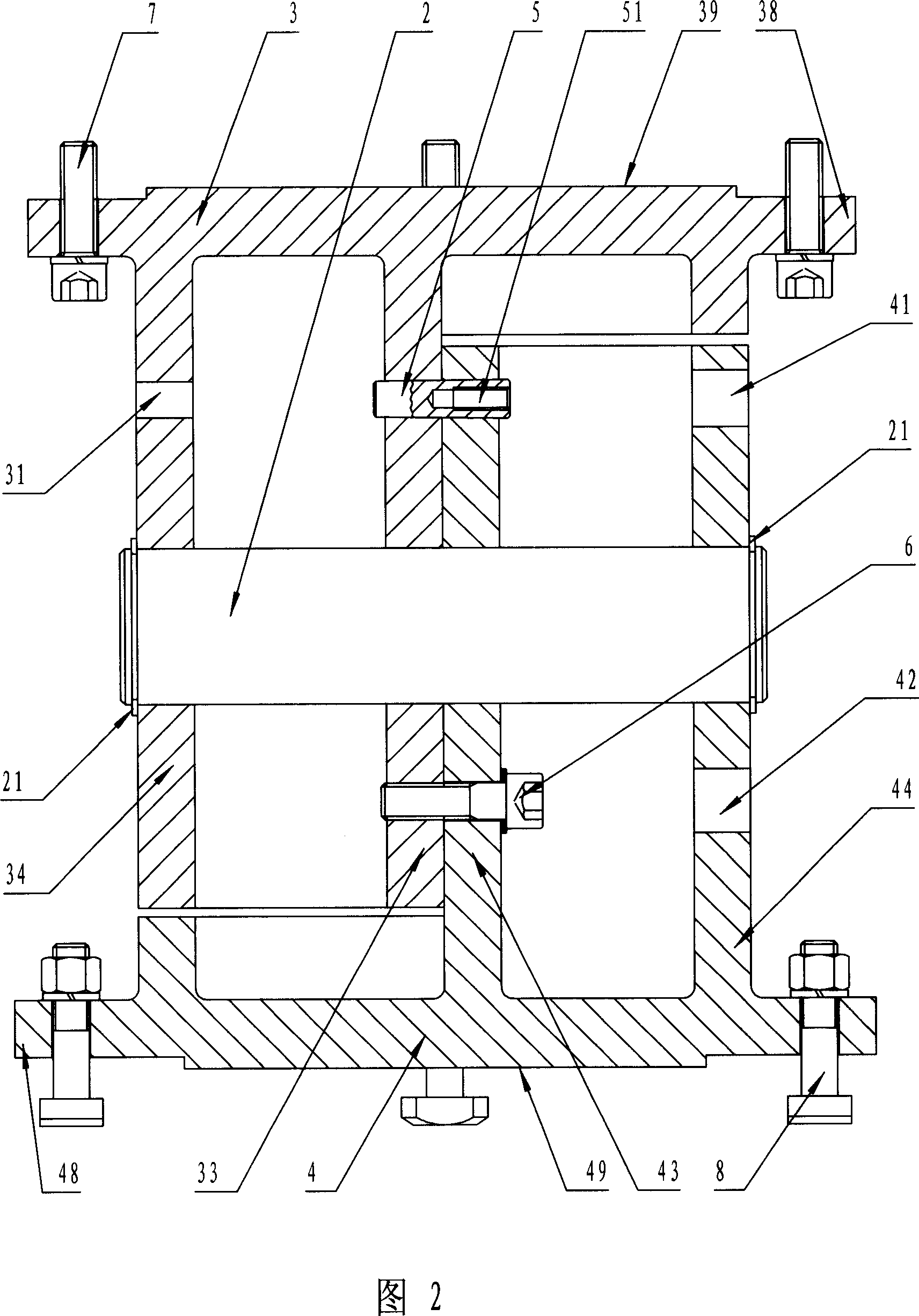

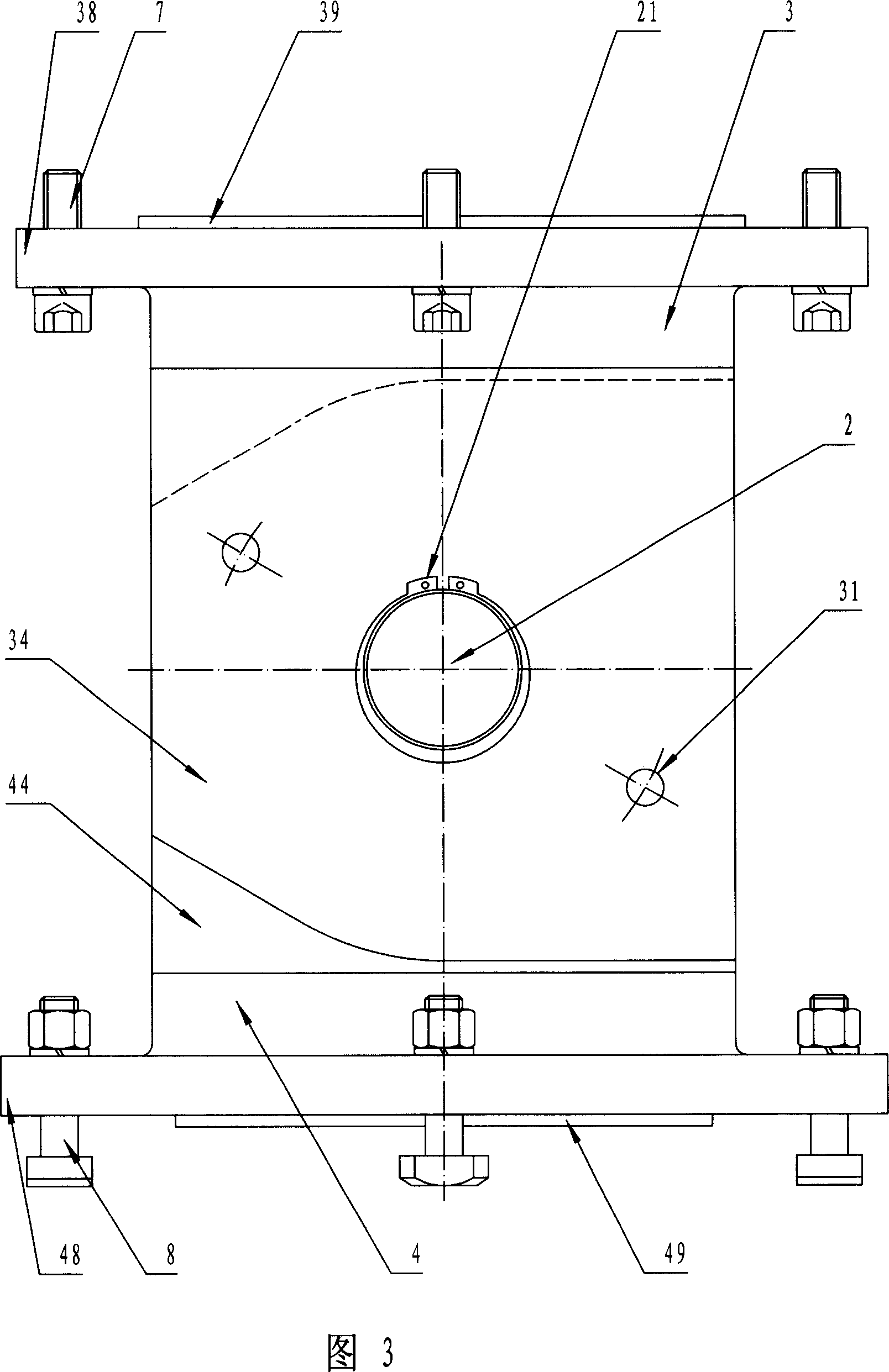

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention should not be limited to this embodiment.

[0017] As shown in Fig. 1, Fig. 2 and Fig. 3, the tilt-type revolving seat according to the present invention includes: a revolving body hinged together by the upper seat 3 and the lower seat 4 through the central pin shaft 2, and its specific connection structure is: The central pin shaft 2 passes through the central shaft hole provided in the upper seat 3 and the lower seat 4, and extends out of the upper seat 3 and the lower seat 4, and is on the corresponding position on the central pin shaft 2 near the outer surfaces of the upper and lower seats 3 and 4 A draw-in slot is provided, and the draw-in slot should ensure that there is a small gap between the upper seat 3 and the lower seat 4, and the retaining springs 21 are installed respectively, so that the upper and lower seats 3 and 4 can rotate smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com