Improved axial force balance mechanism of centrifugal pump impeller

A centrifugal pump impeller and balance mechanism technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, can solve the problems of centrifugal pump impeller axial force balance structure, etc., and broaden the scope of use and occasions, the effect of energy loss reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

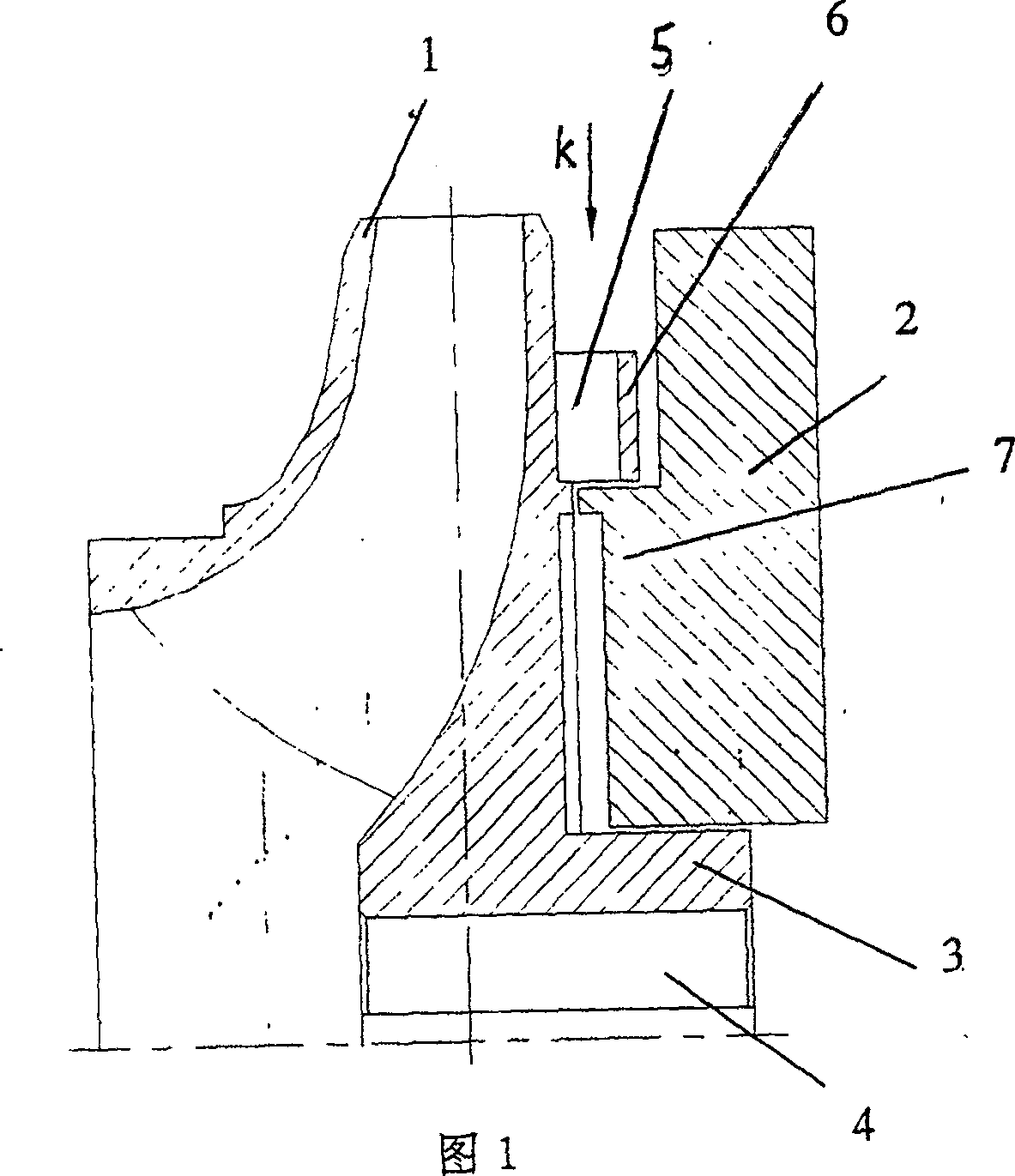

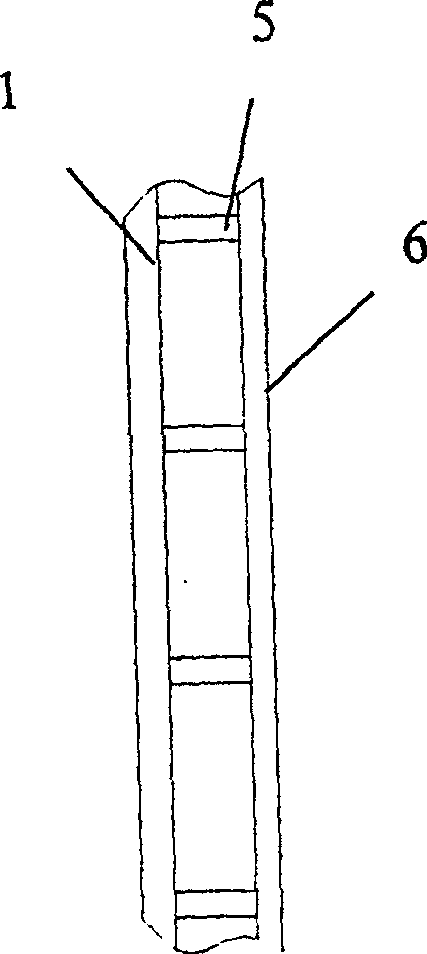

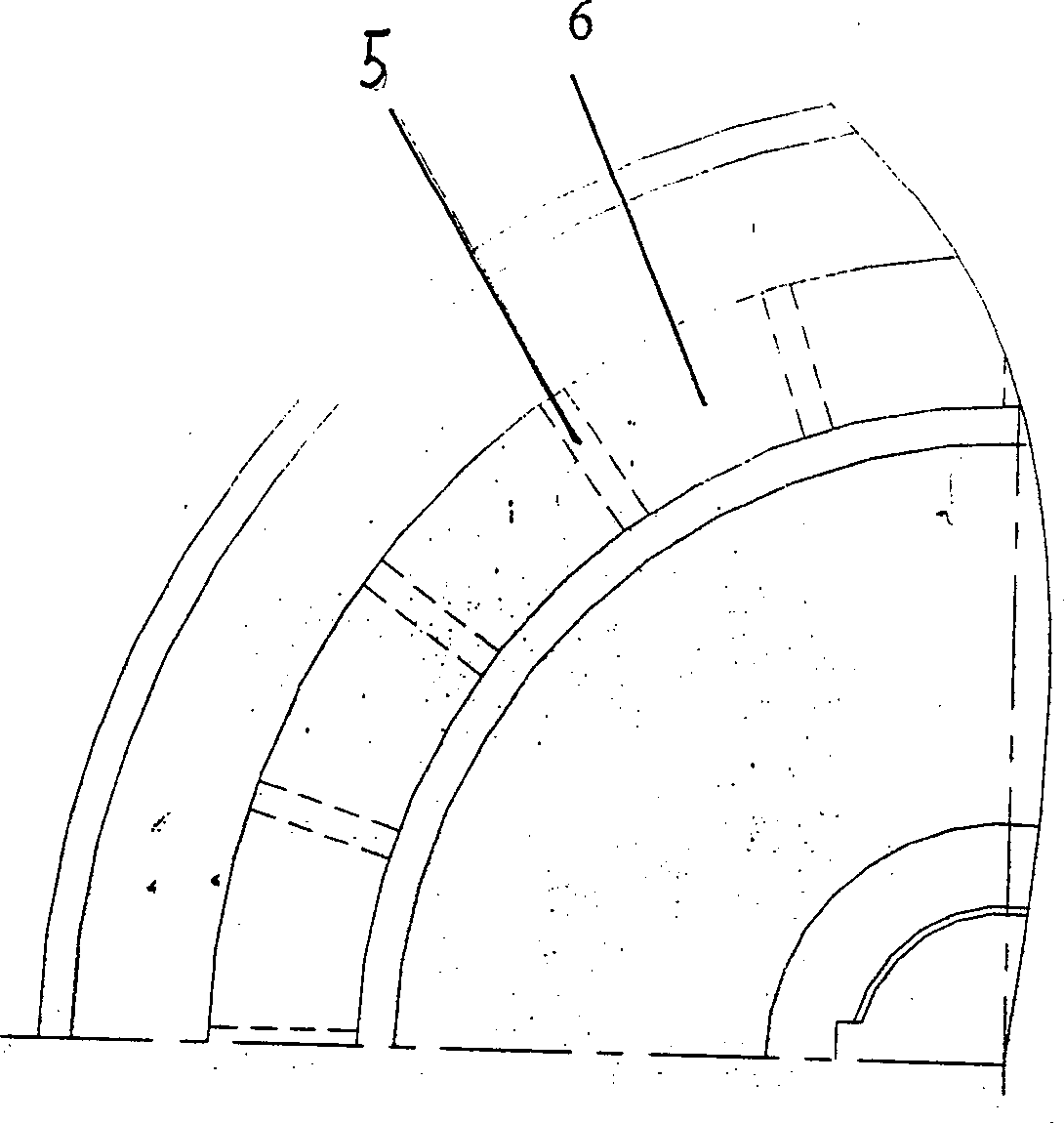

[0013] Figure 1, figure 2 and image 3 As shown, the axial force balance mechanism of the improved centrifugal pump impeller of the present invention is composed of a centrifugal pump impeller 1 and a pump cover 2. The axial center position of the centrifugal pump impeller 1 is provided with a shaft sleeve 3, and the shaft The sleeve 3 is fixedly arranged on the pump shaft 4, the pump shaft 4 is arranged in the pump body, the pump cover 2 is arranged on the pump body, wherein, the back side of the centrifugal pump impeller 1 is fixedly arranged with plural radial back blades 5, the plurality of radial back blades 5 are evenly spaced along the circumferential direction, any one of the radial back blades 5 is perpendicular to the rotation plane of the centrifugal pump impeller 1, any one of the radial back blades 5 and the centrifugal pump impeller 1 There are gaps between the outer circumferences of the shaft sleeves 3, the lengths of any two adjacent radial back blades 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com