Automobile safety anti-collision shock-proof system

A shock absorption system and automobile safety technology, applied in the direction of bumpers, etc., can solve the problems of limited cushioning capacity of hollow tubes and unsatisfactory effects of hollow tube bumpers, and achieve the effects of reducing damage, reducing danger, and improving mitigation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

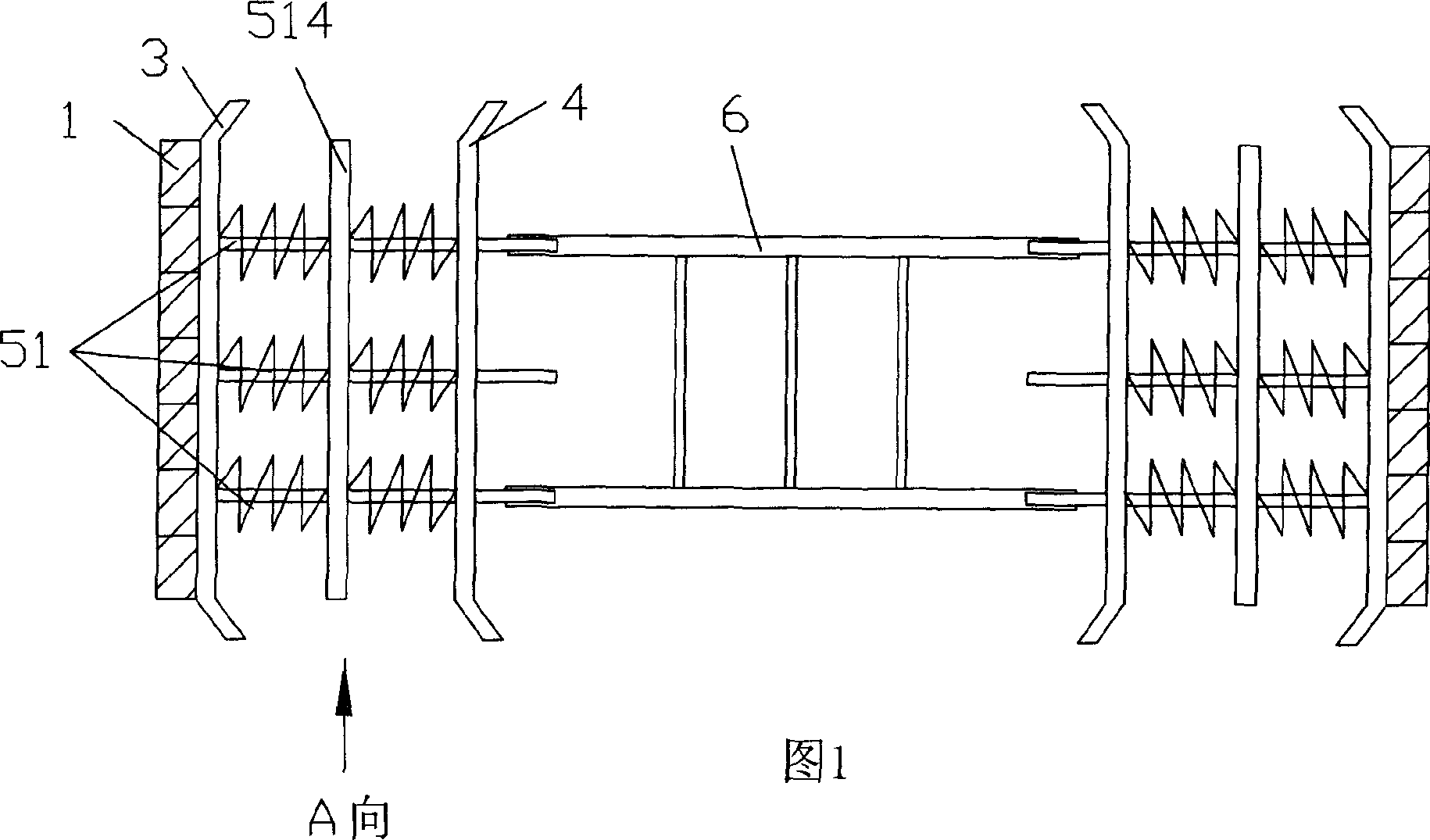

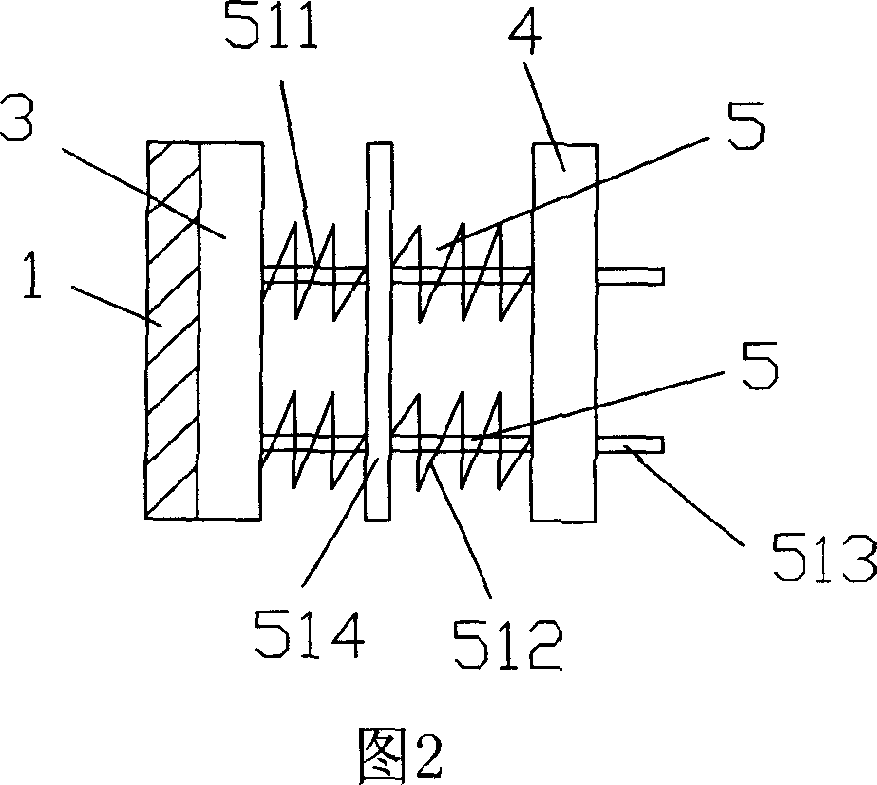

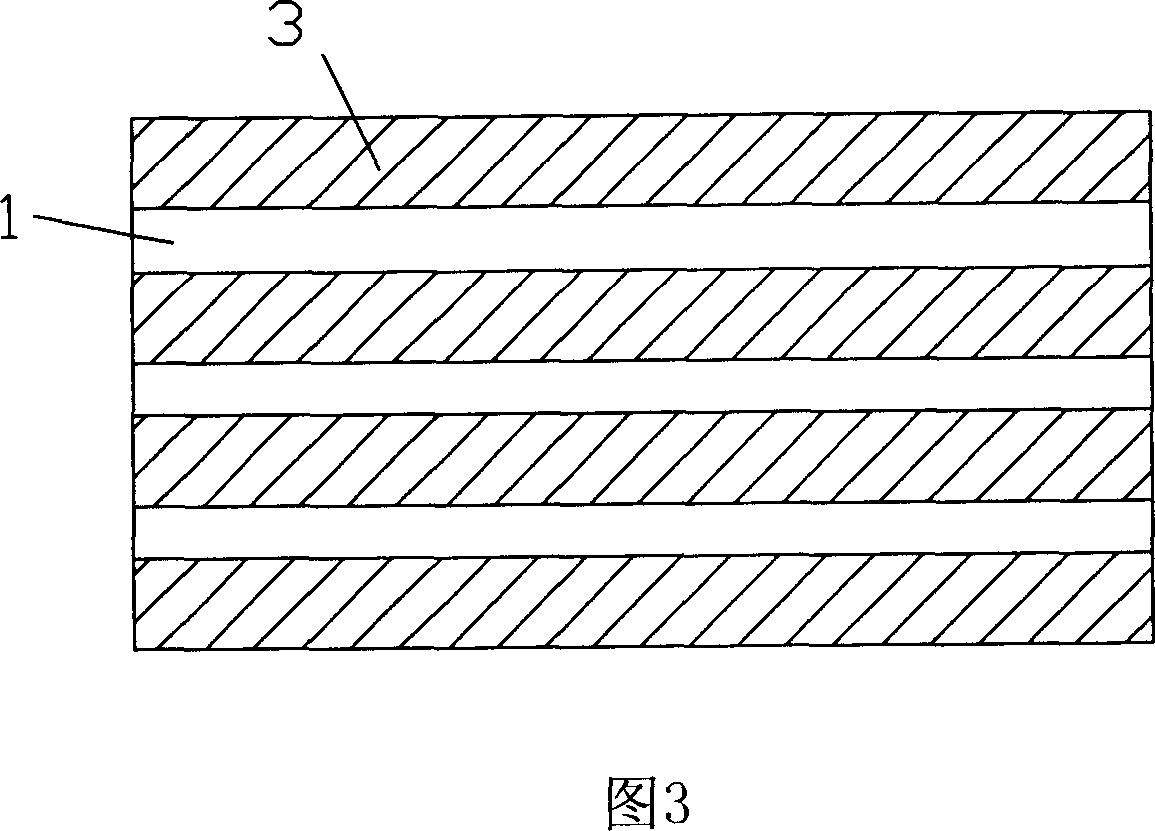

[0015] As shown in Figures 1 and 2, the automobile safety anti-collision shock absorption system of the present invention is composed of an elastic buffer layer 1 and a spring assembly 2. Layer spring group 5 is formed, and each layer of spring group all includes several groups of spring assemblies 51 that are uniformly distributed along the length direction of the elastic buffer layer 1, and each group of spring assemblies 51 is composed of mutually independent front shock absorbing springs 511, rear shock absorbing springs 512, spring The central rod 513 and the middle pressure plate 514 are composed of the spring center rod 513 passing through the middle pressure plate 514 and the rear fixed plate 4 and can slide relative to the middle pressure plate 514 and the rear fixed plate 4. One end is fixed on the front fixed plate 3, and the other end is a fixed The fixed end corresponds to the chassis of the car. The front shock absorbing spring 511 is set on the spring center rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com