Stacking frame structure of superwide container

A container and frame structure technology, applied in the field of stacking frame structure, can solve the problems of container cargo space occupation, insufficient strength, unsafe use, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

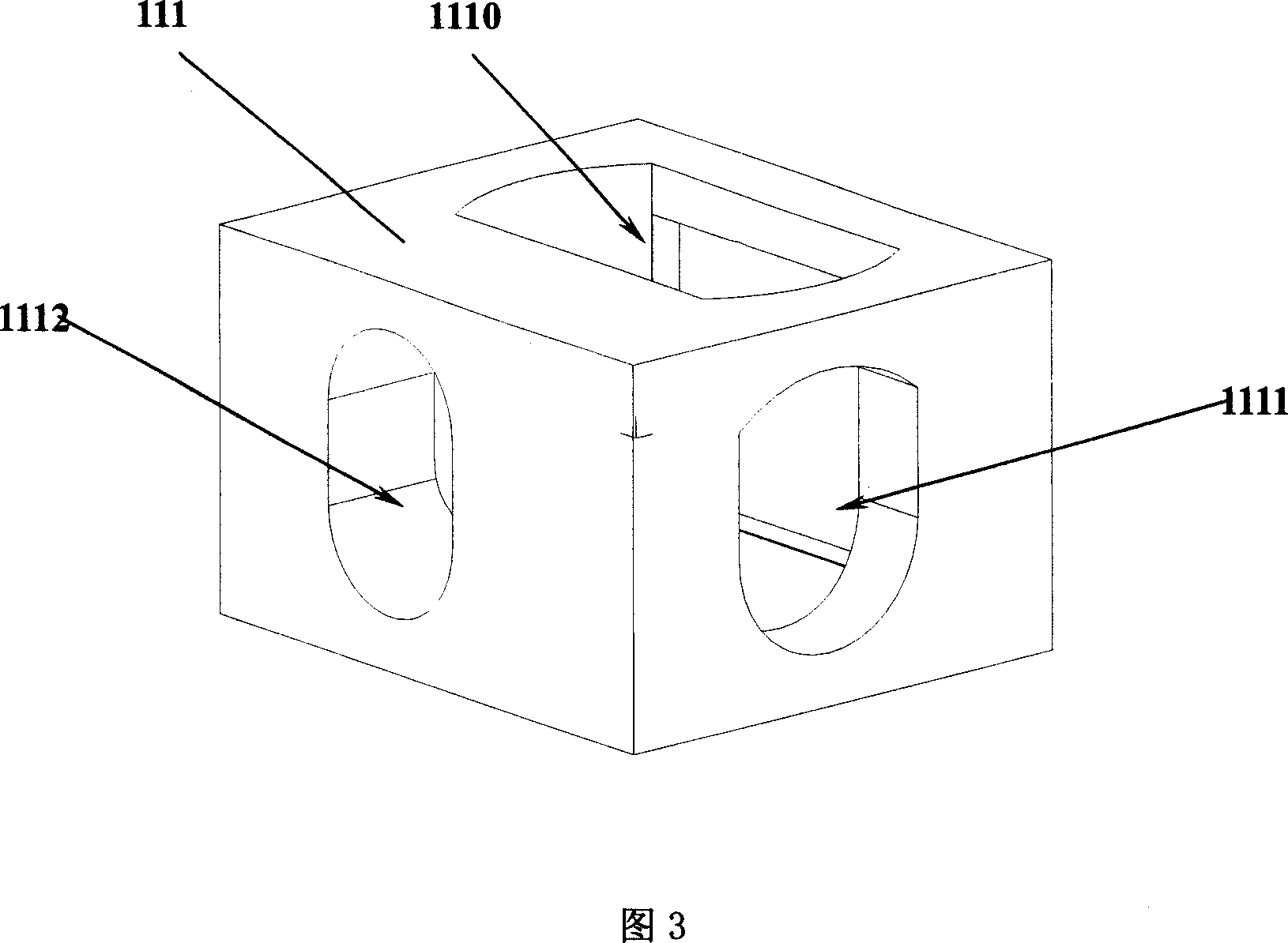

[0029] As shown in Figure 7, a stacking frame structure 31 of an ultra-wide container includes corner posts 310 on both sides, a top corner piece 311 arranged at the top of the corner post 310, a bottom corner piece 312 at the bottom of the corner post 310, and a horizontally connected The upper beam 313 between the two top corner pieces 311 and the lower beam 314 between the two bottom corner pieces 312, the top corner pieces at both ends of the top corner of the stacking frame are provided with three lifting holes, two of which are parallel to each other. Adjacent to the top of one end corner fitting 311 at the top corner of the stacking frame, there are respectively inner holes 3112 and outer holes 3111, and the third lifting hole 3110 is arranged at the other end corner fitting 311' at the top corner of the stacking frame. At the top, the distance between the center of the inner hole 3112 on the corner fitting 310 and the center of the lifting hole 3110 of the corner fittin...

Embodiment 2

[0032] As shown in Figures 9 and 10, the double-hole corner fitting used in this embodiment adopts the earliest design of British REYNARD INTERMODAL ENGINEERING. When the turnlock goes deep into the inner hole 3112, it will force the flexible diaphragm 3113 to deflect, providing space for the deep turnlock ; When the twist lock withdraws, the flexible diaphragm 3113 returns to its original shape, so that the thickness of the corner piece can be reduced a lot, so as to achieve the purpose of increasing the loading space as much as possible.

Embodiment 3

[0034]As shown in Figure 11, the inner and outer holes 3112, 3111 are respectively located on two separate corner fittings 311" and 311, so that the most common corner fittings can be used respectively, and they can be combined according to different positions to have a larger Flexibility saves costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com