Method and apparatus of calibrating parameters of servo signals

A signal and parameter technology, applied in the parameter field of servo signals, can solve the problems of reducing the accuracy of servo control, endangering the quality of optical drive data access, optical path deviation, etc., to achieve the effect of improving programming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

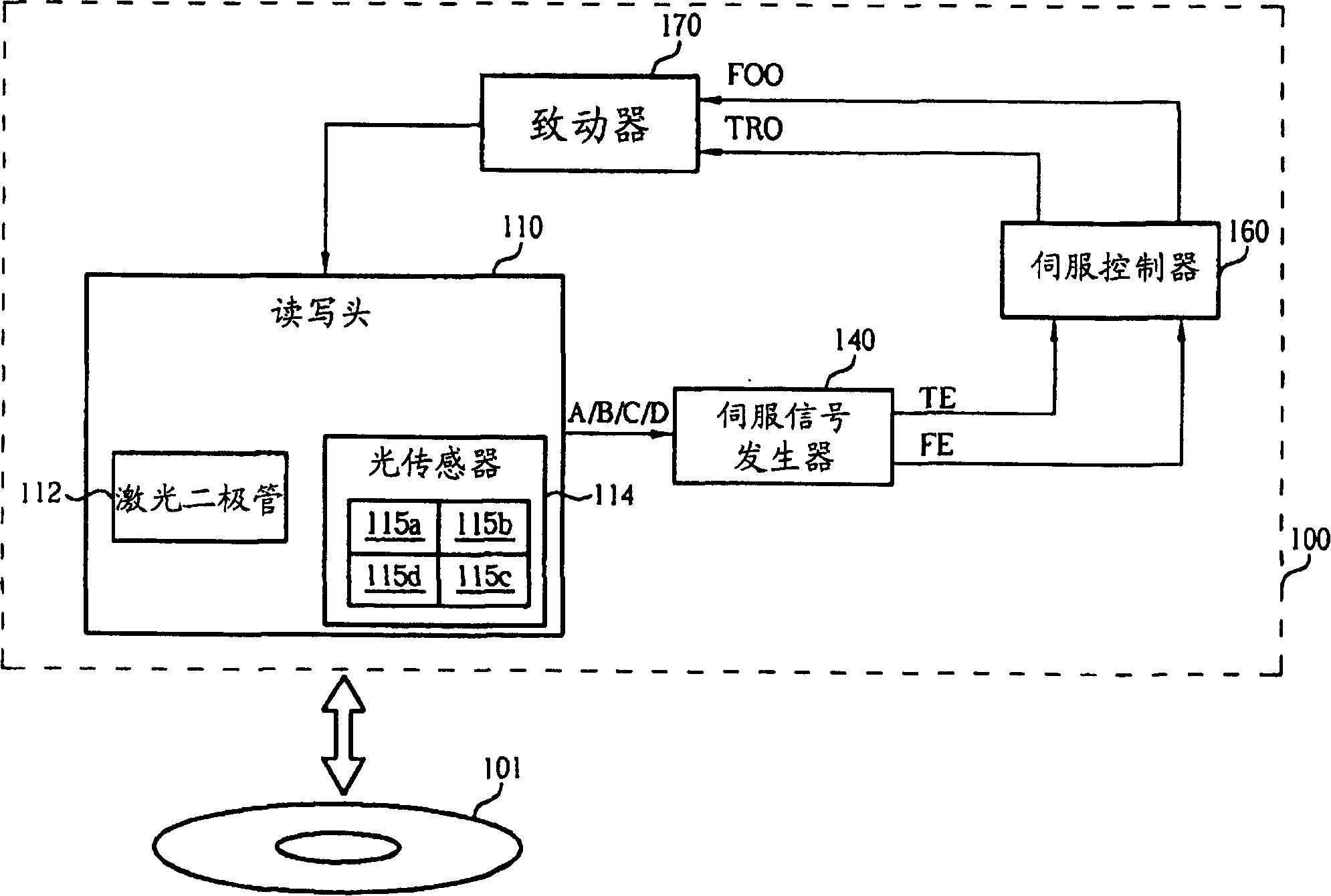

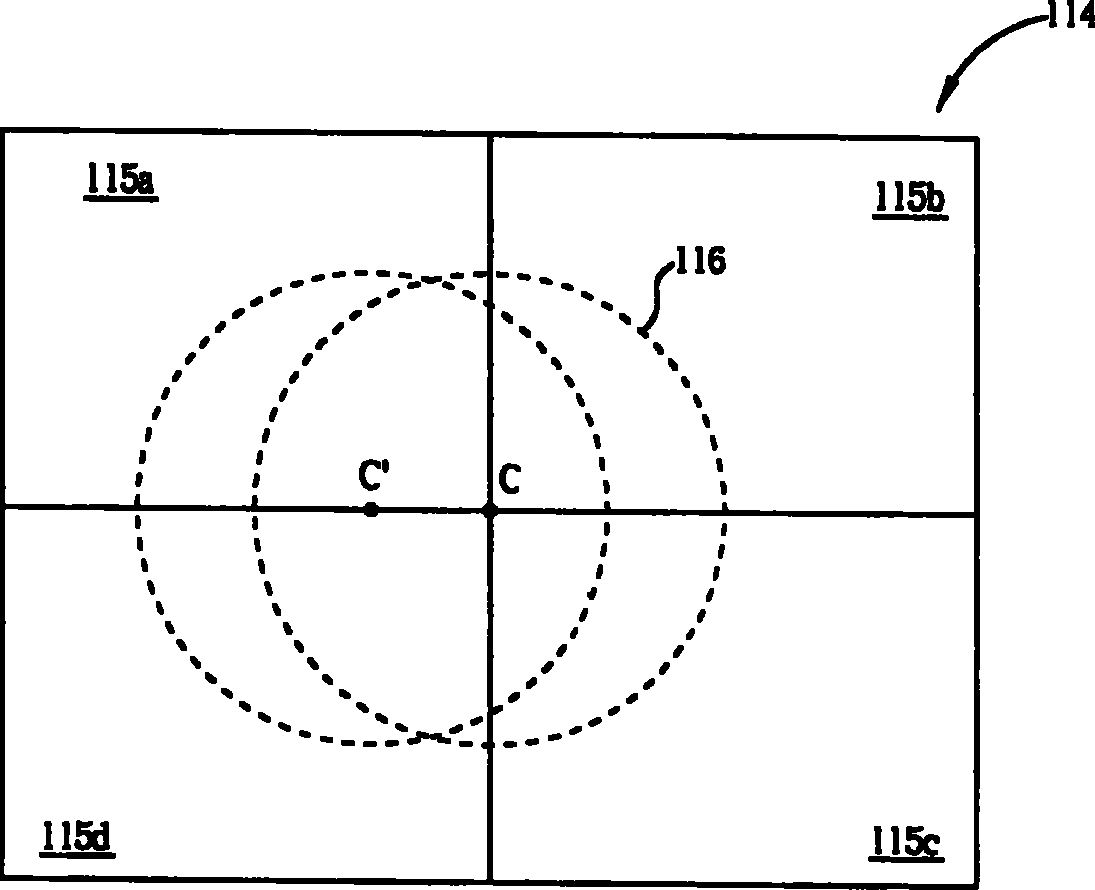

[0045] see Figure 4 , Figure 4 It is a functional block diagram of an optical drive 400 (such as a DVD optical drive) according to the first embodiment of the present invention. because figure 1The device shown with the Figure 4 Components with the same names in the shown devices have the same functions and operations, and thus will not be repeated here.

[0046] In this embodiment, in order to compensate the focus error signal FE, the system uses a focus error offset (FE offset) to adjust the servo control operation. For example, the servo signal generator 440 can use the synthesized detection signals A, B, C and D to generate the focus error signal FE according to the following equation:

[0047] FE=(A+C)-Kb*(B+D)+FE offset formula (1)

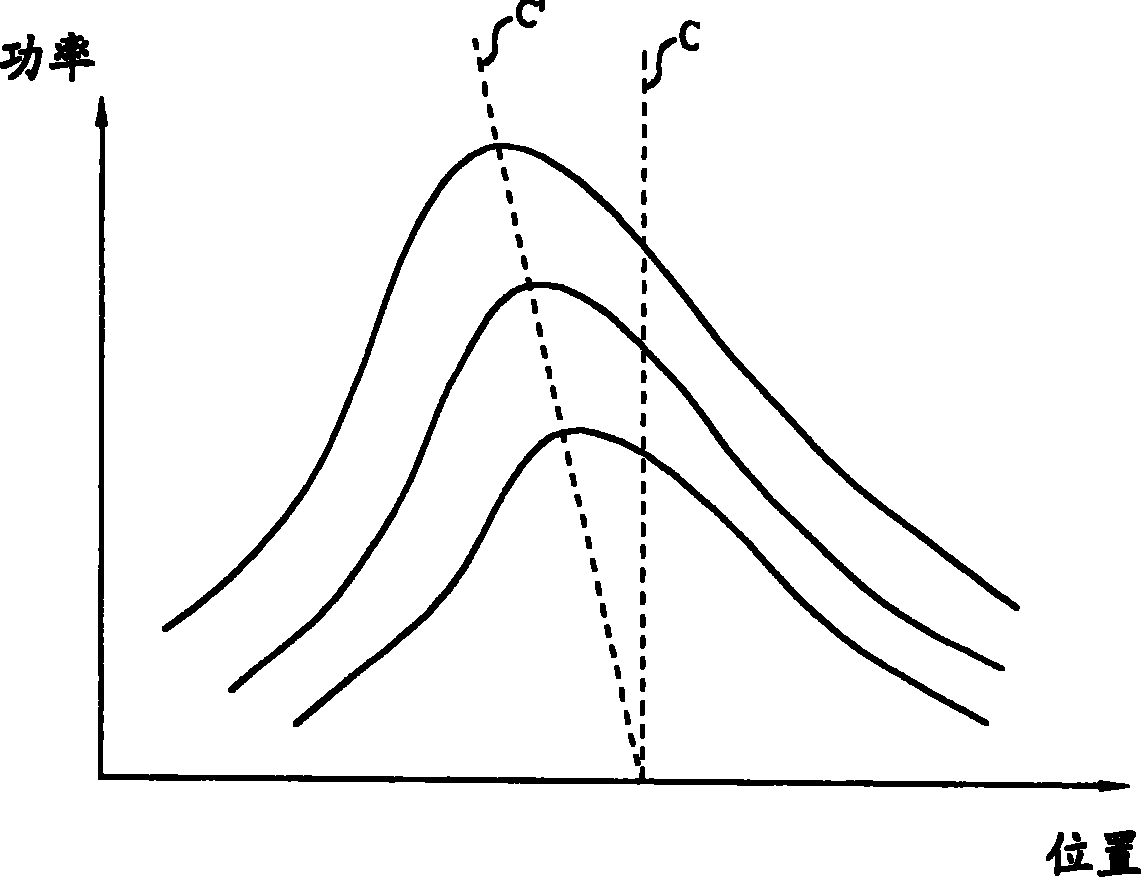

[0048] Please note that the Kb value in formula (1) is a parameter value used to adjust the ratio of the sum of the detection signals A and C and the sum of the detection signals B and D. In order to optimize the focus control, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com