Method for compensating label surface of optical disk radially

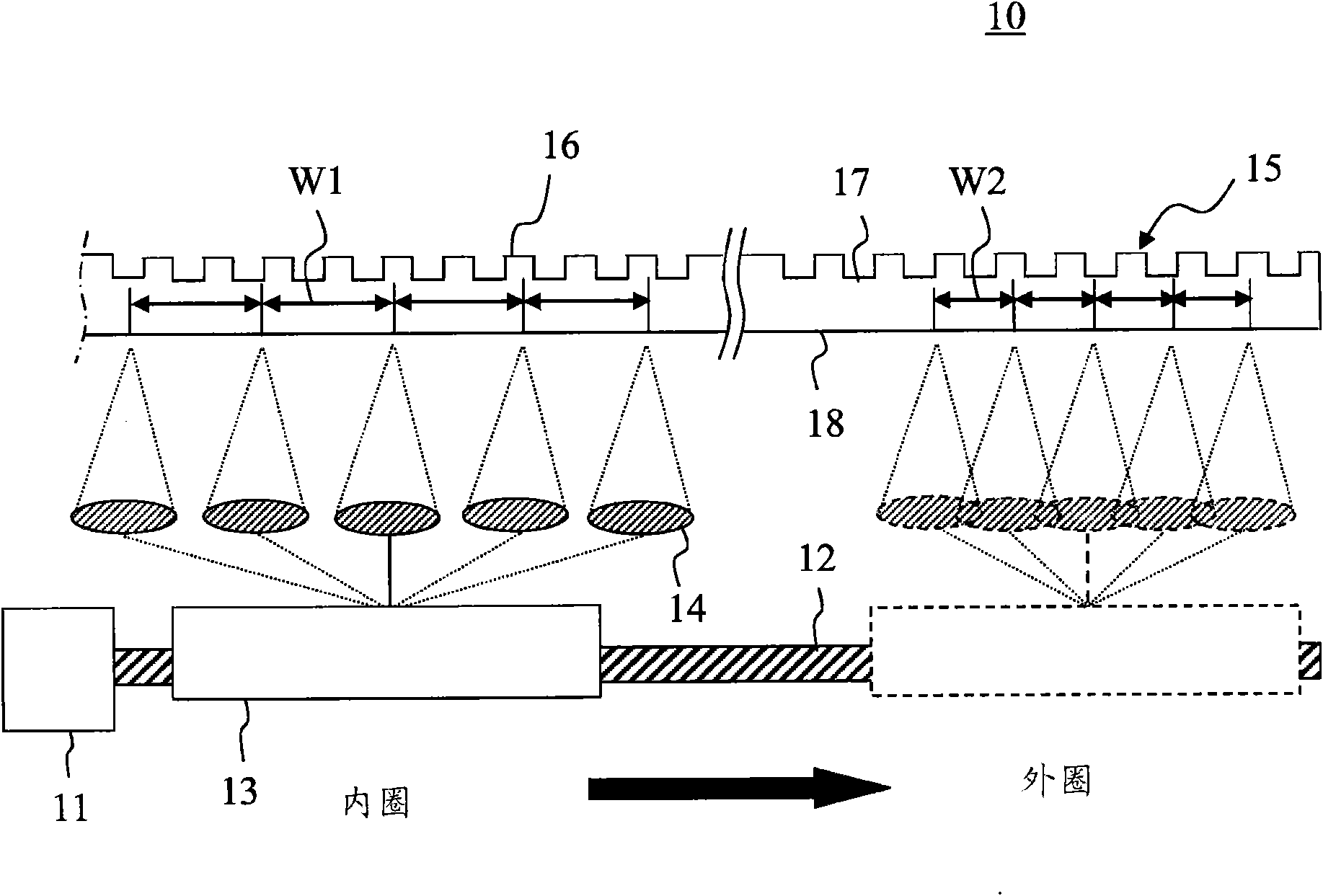

A compensation method and label surface technology, applied in the directions of record carrier accessories, instruments, packaging, etc., can solve the problems of inability to draw a uniform pattern and uneven density of pattern lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

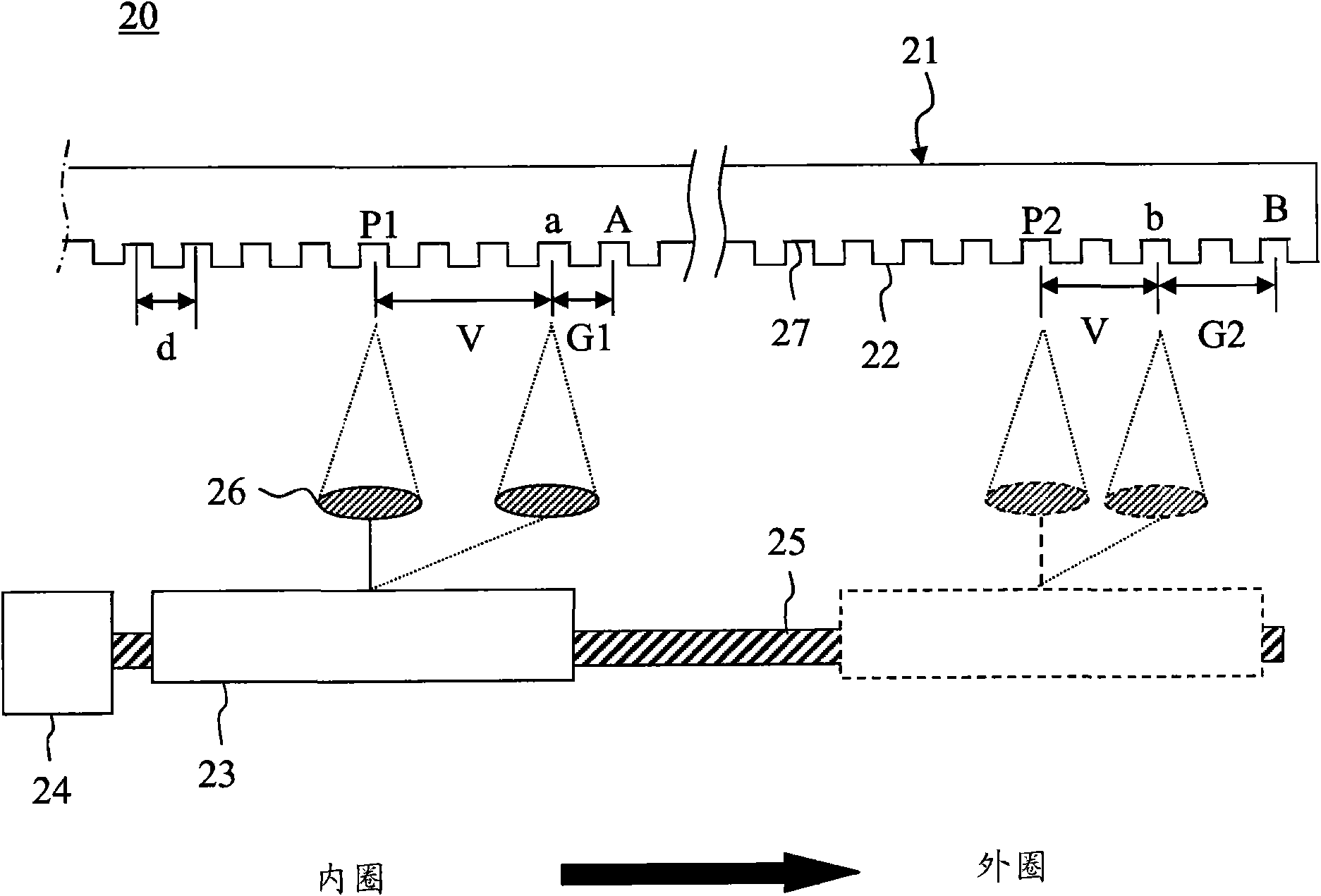

[0034] With regard to the technical means and effects adopted by the present invention to achieve the above-mentioned objects, preferred embodiments are described below with accompanying drawings.

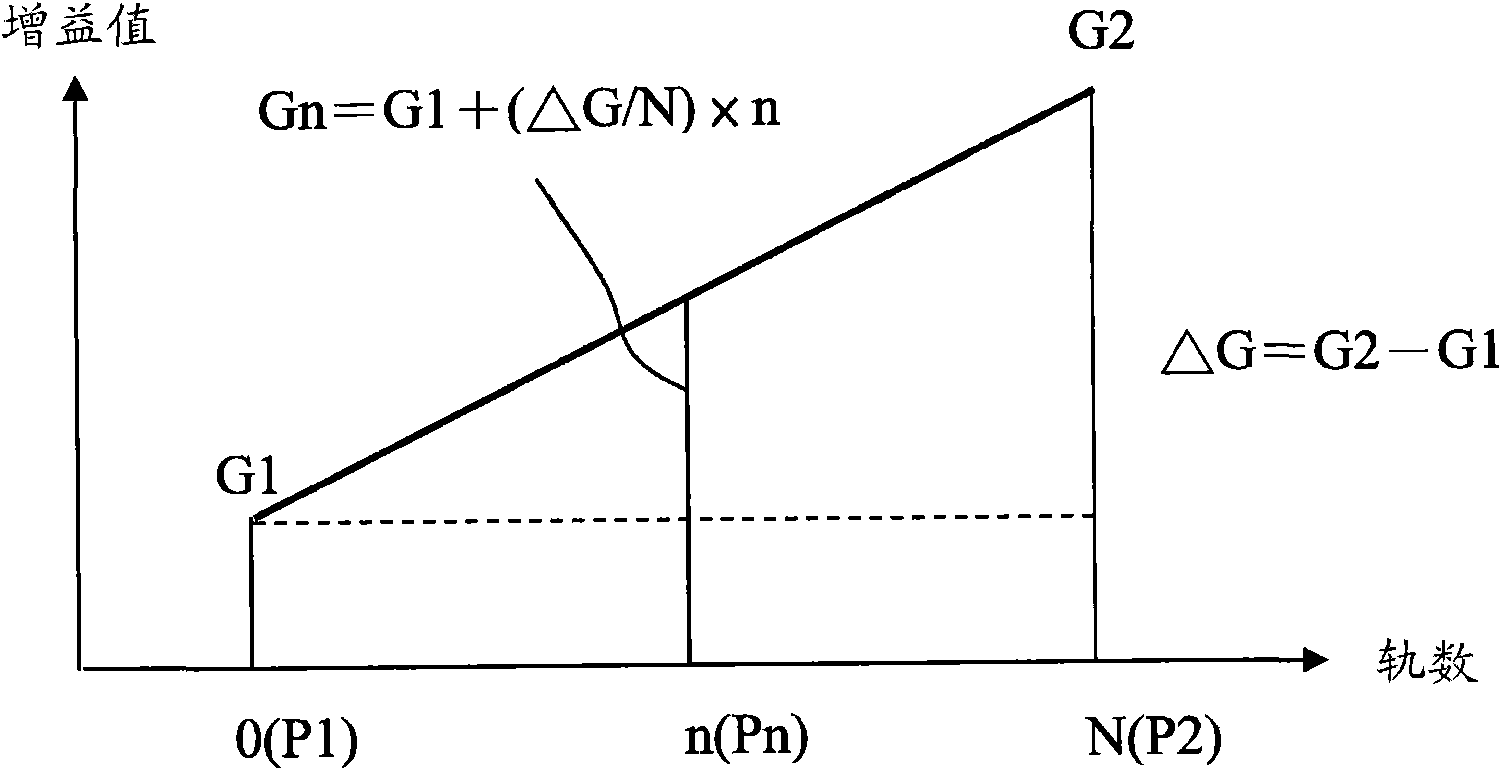

[0035] Please refer to figure 2 , Is a schematic diagram of the radial compensation method for the label surface of the optical disc according to the first embodiment of the present invention. First, put the optical disc 21 in the optical engraving machine 20 so that the data surface 22 faces the optical pickup 23. The stepping motor 24 is controlled to rotate the lead screw 25, and the coarse adjustment optical pickup 23 moves to a specific point P1 of the inner circle of the optical disc 21, and the best position of the specific point P1 is the starting point of the inner circle. The objective lens 26 is driven by the voltage V required to move to the target distance A set by the optical engraving machine 20. The actual movement distance a of the objective lens 26 can be calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com