Electrode and electric dirt collector

A technology for electric dust collectors and electrodes, which is applied in the field of electric dust collectors and can solve problems such as the reduction of the dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

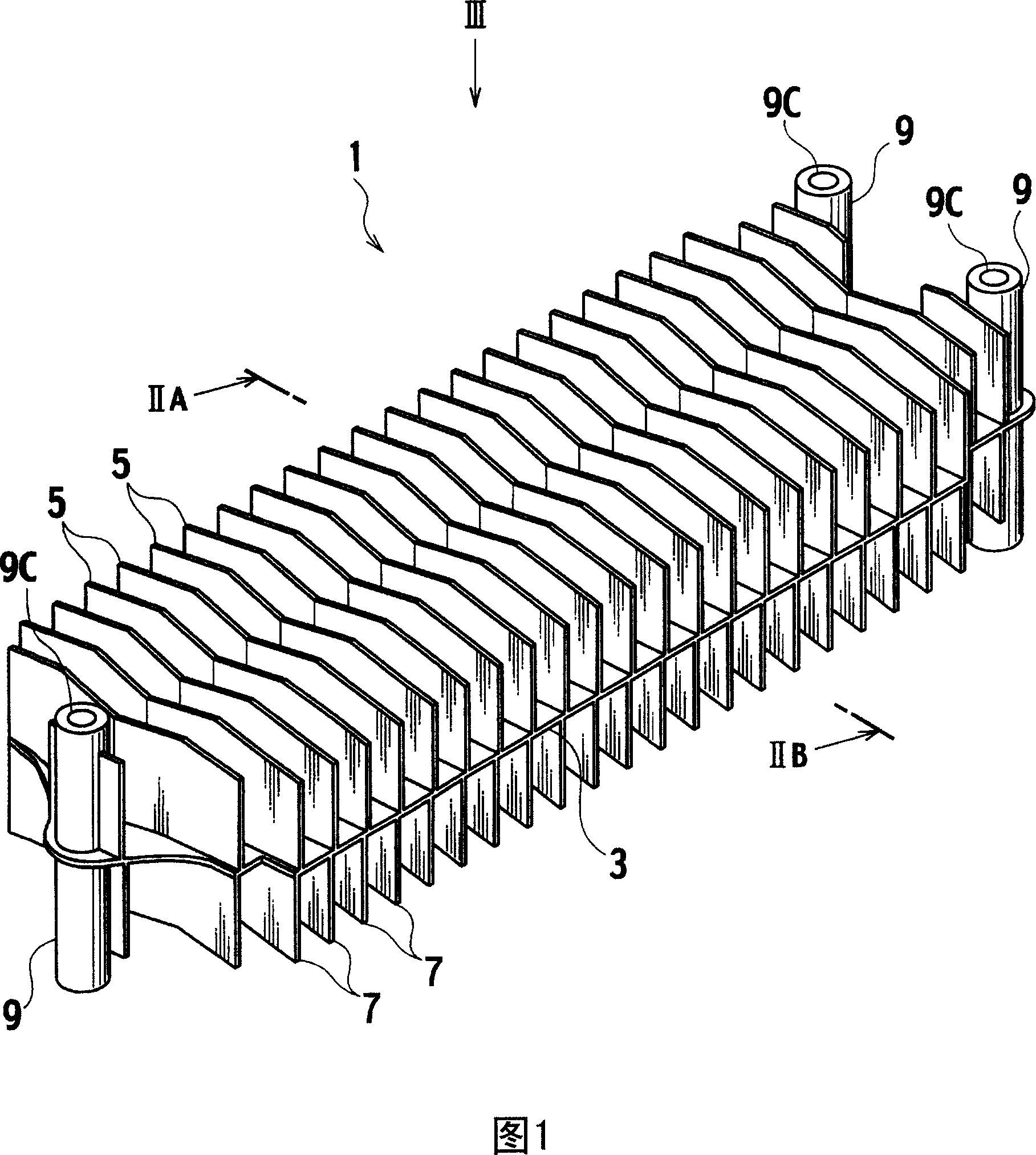

[0037]Fig. 1 is a perspective view showing a schematic configuration of an electrode 1 of an electrostatic precipitator according to a first embodiment of the present invention.

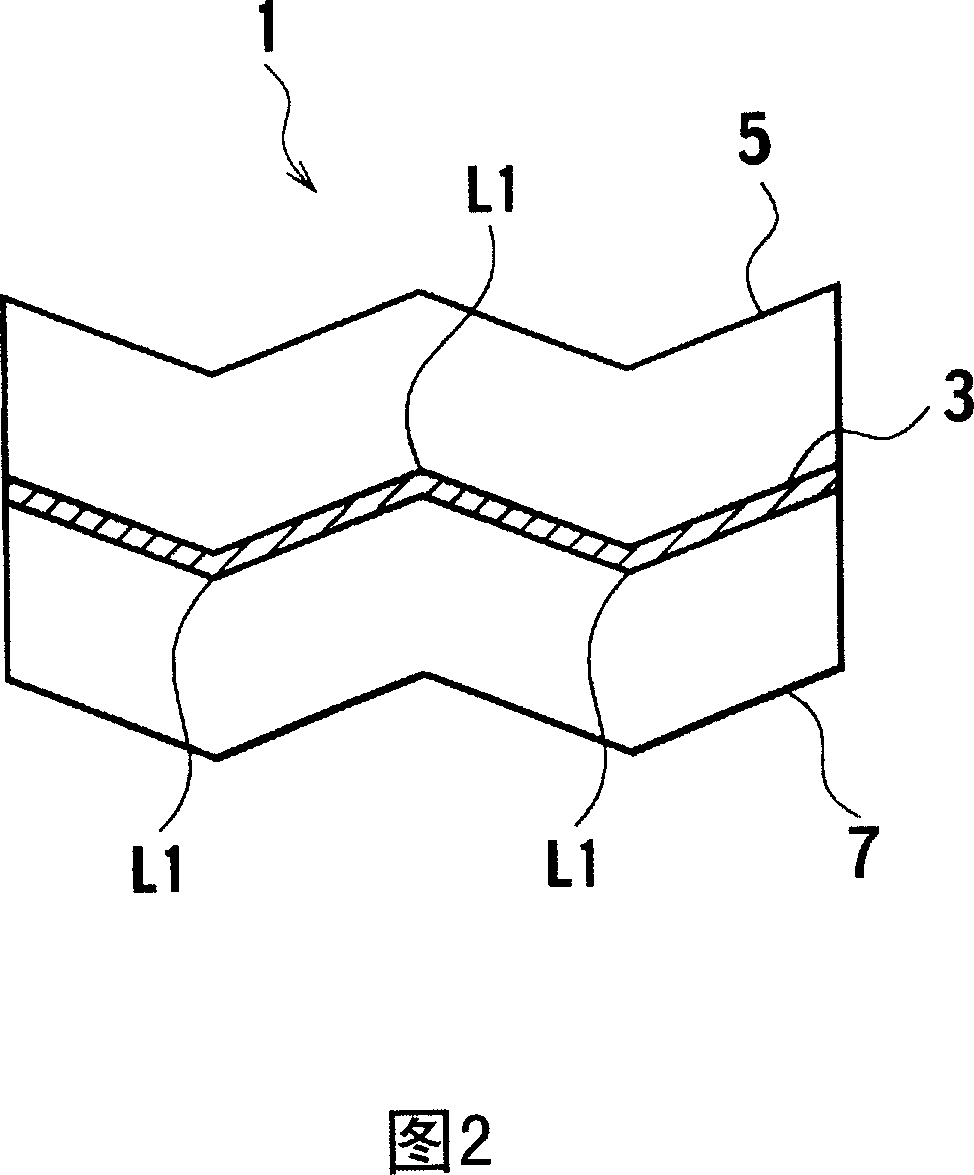

[0038] Fig. 2 is a diagram showing a section IIA-IIB in Fig. 1 .

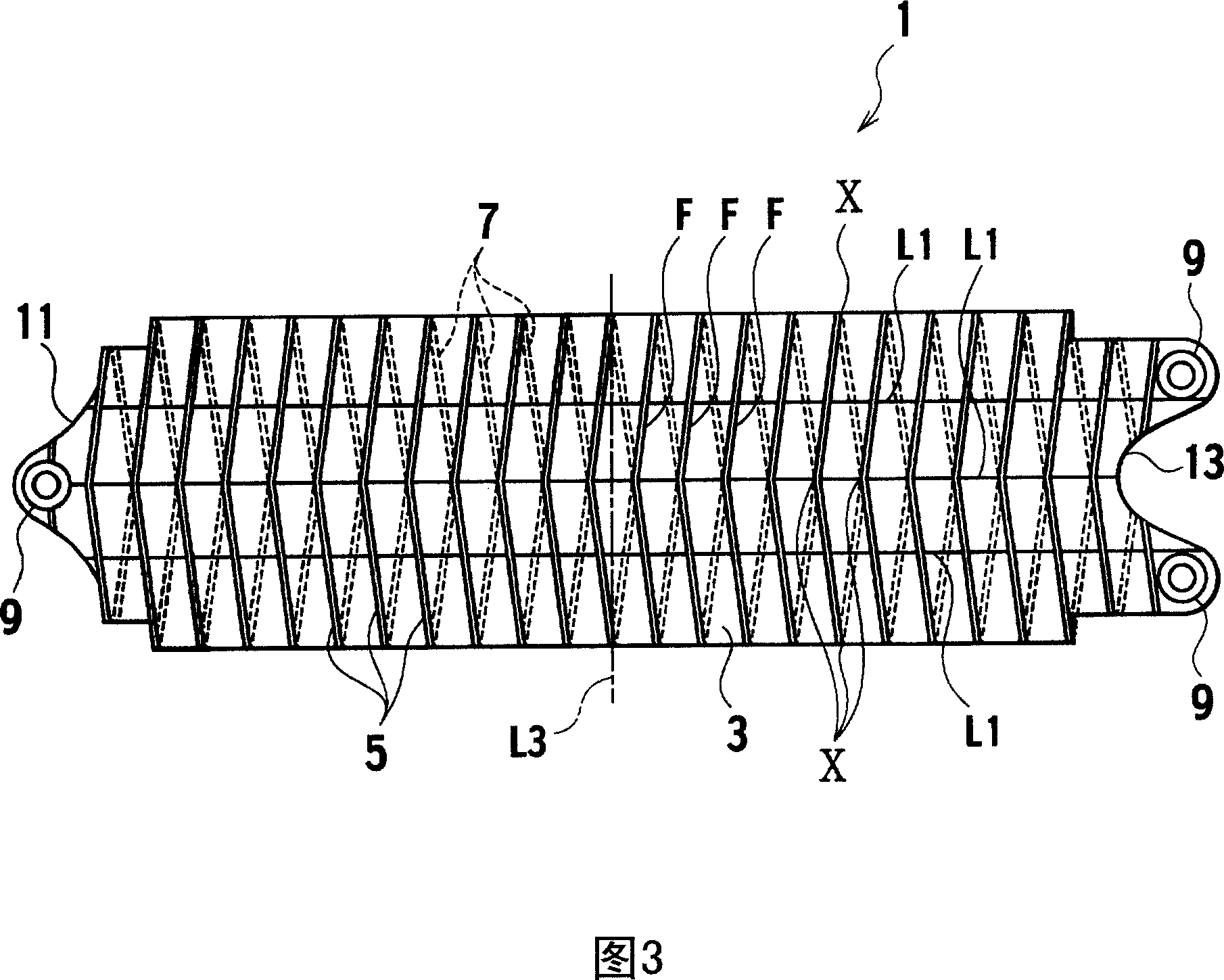

[0039] FIG. 3 is a view showing the direction III in FIG. 1 , and is a plan view showing a schematic configuration of the electrode 1 .

[0040] The electrode (for example, the capture-side electrode) 1 is used as an electrode of an electric dust collector for capturing charged dust, and is equipped with a conductive plate-shaped base member 3 .

[0041] In addition, first ribs 5 and second ribs 7 formed of conductive members are provided on each of both surfaces in the thickness direction of the above-mentioned plate-shaped base member (base plate) 3 .

[0042] In addition, a plurality of the first ribs 5 are provided on one surface of the base member 3 at a predetermined interval, and a plurality of the second ribs 7 are provided o...

no. 2 approach

[0112] Fig. 10 is a perspective view showing a schematic configuration of an electrode 1e according to a second embodiment of the present invention, and is a view corresponding to the direction III in Fig. 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com