Float positioning device of welding machine

A floating positioning and welding machine technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of wear of the positioning plate and the front pressure clamp, inaccurate positioning of the positioning plate, inconvenient adjustment, etc., to ensure the accuracy , The effect of eliminating size error and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

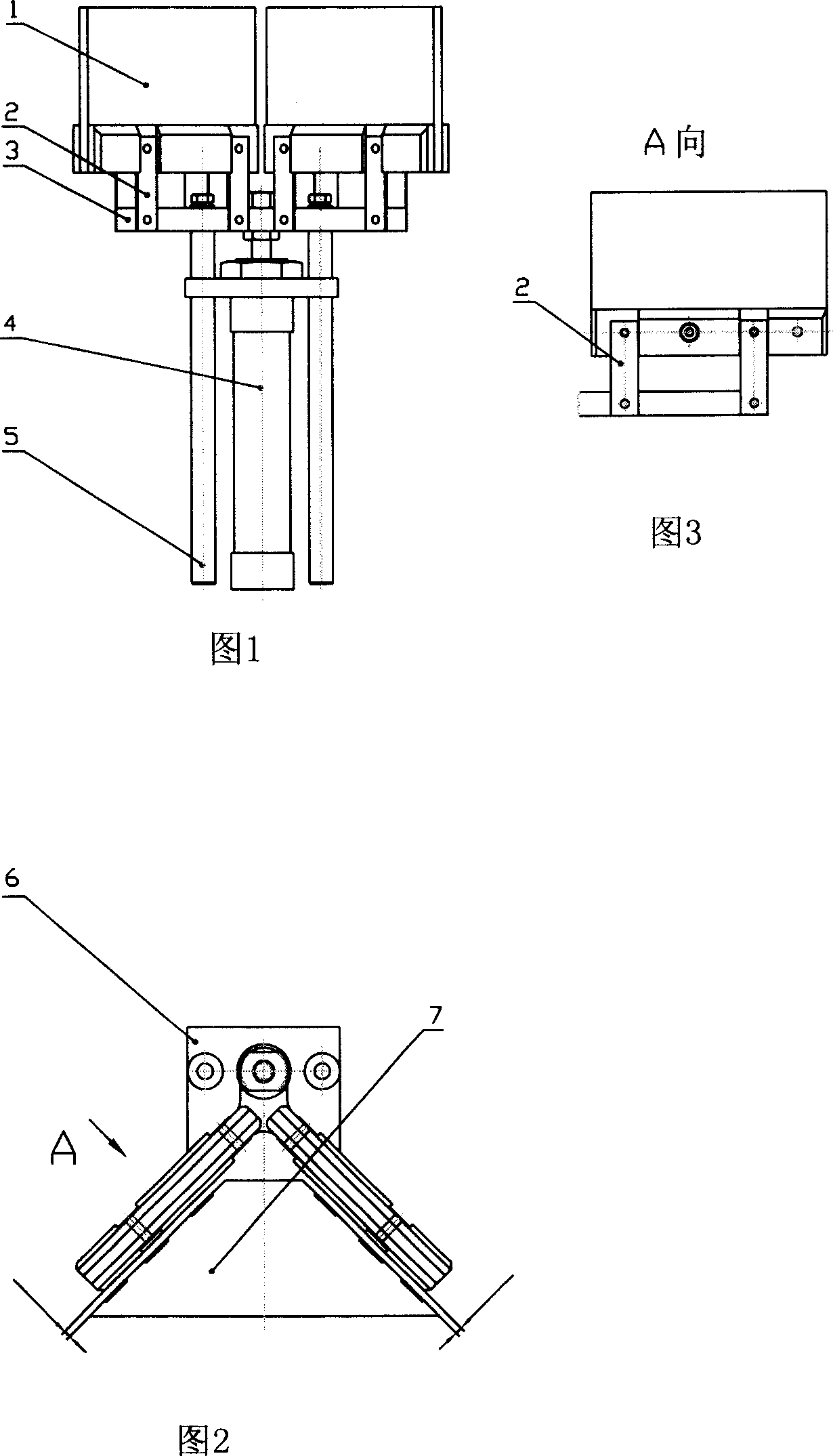

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. The welding positioning plate 1 of this embodiment is connected and fixed on the positioning plate support 3 through the spring leaf 2, the cylinder rod of the positioning plate movement cylinder 4 is fixed on the positioning plate support 3, the cylinder 4 is fixed on the cylinder mounting plate 6, and the guide shaft 5 Pass through the cylinder mounting plate 6 through the guide sleeve. During work, the positioning plate 1 rises upwards along the positioning plate movement guide shaft 5 under the action of the positioning plate movement cylinder 4, and is higher than the front pressure clamp 7 of the welding machine to locate the required welding profile. Since we adjusted the gap between the welding positioning plate 1 and the front pressure clamp 7 of the welding machine to 3-5mm during design and installation, it ensured that the two workpieces would not touch and wear, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com