Method for metering oil production yield and analyzing and optimizing operating condition of oil well and system thereof

An optimization method and technology for liquid production, which can be used in surveying, earth-moving drilling, wellbore/well components, etc., to solve the problems of complex flow regime, few successfully put into use, and non-uniform mixing, etc., to achieve high reliability, The effect of low cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

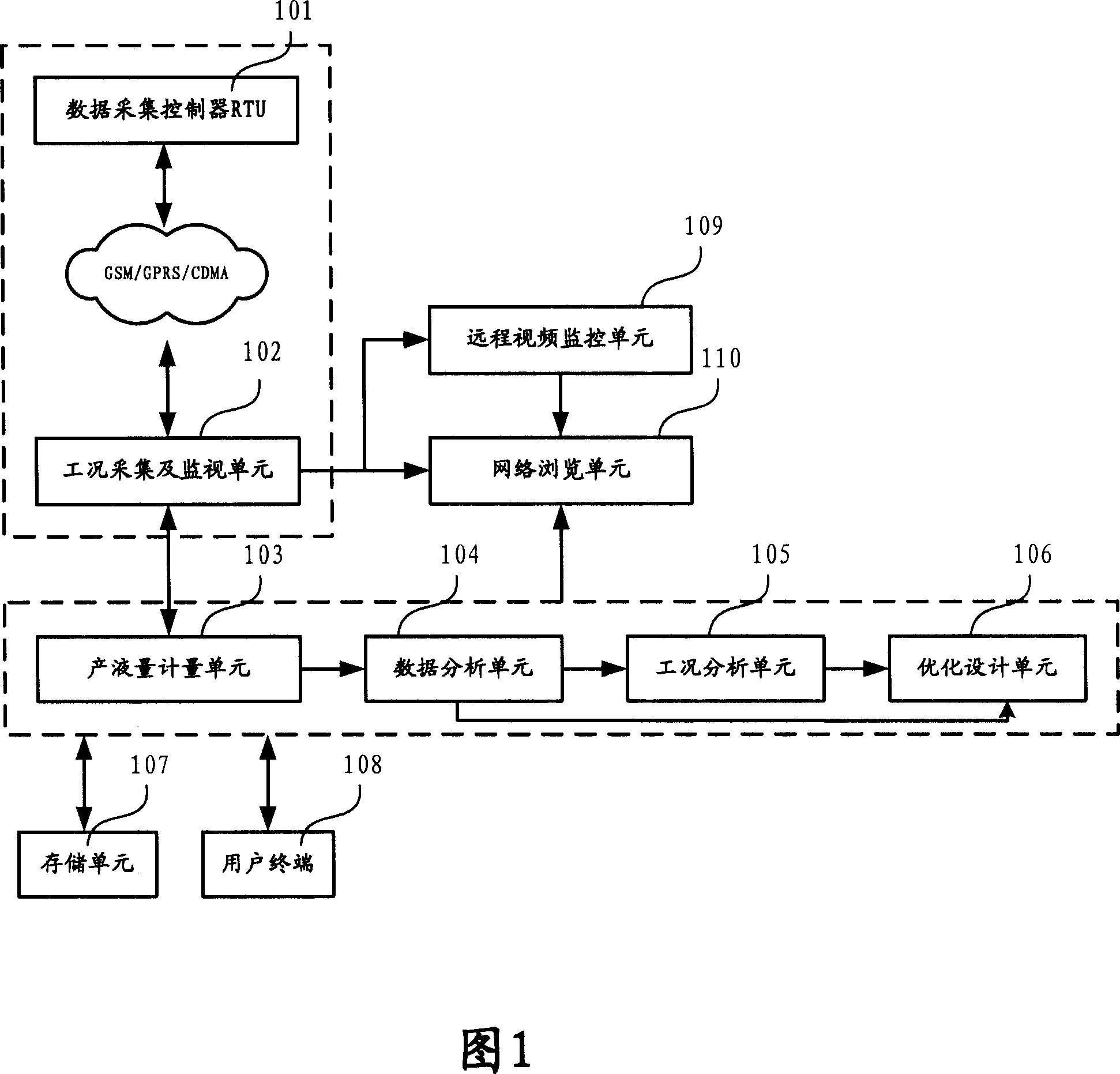

[0054] The invention provides an oil well fluid production measurement, working condition analysis and optimization system. As shown in Figure 1, the system at least includes: a data acquisition controller (RTU) 101, a working condition acquisition and monitoring unit 102, and a liquid production measurement unit 103; wherein,

[0055]The data acquisition controller RTU101 is installed in the oil well and connected with the sensor set on the oil well pumping unit, used to collect the working condition data of the sensor and transmit the working condition data to the working condition acquisition and monitoring through the wireless communication network Unit 102, and control the oil well; wherein, the control of the oil well refers to the intelligent control of the oil well such as opening, stopping, and issuing sound alarms for starting and stopping the well;

[0056] The working condition acquisition and monitoring unit 102 performs information interaction with the data acqui...

Embodiment 2

[0080] The present invention also provides a method for oil well fluid production measurement and working condition analysis and optimization. The method is completed by the above-mentioned measurement system. The method includes the steps of:

[0081] The data acquisition controller 101 acquires the working condition data transmitted by the sensor set on the oil well pumping unit, and transmits the working condition data to the working condition collecting and monitoring unit 102 through the wireless communication network;

[0082] The working condition acquisition and monitoring unit 102 receives and processes the working condition data, and transmits the working condition data to the fluid production metering unit 103, and monitors the operating status of the oil well; wherein, the working condition data is processed It refers to encrypting and packing the working condition data; the operating status of the oil well specifically refers to: whether the well is open, whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com