Direct lighting backlight module

A backlight module, direct-type technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as difficult to meet the brightness requirements of liquid crystal display panels, high cost of direct-type backlight modules, and reduced brightness of outgoing light, etc., to achieve improved The effect of light brightness and light uniformity, low cost, and small beam energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

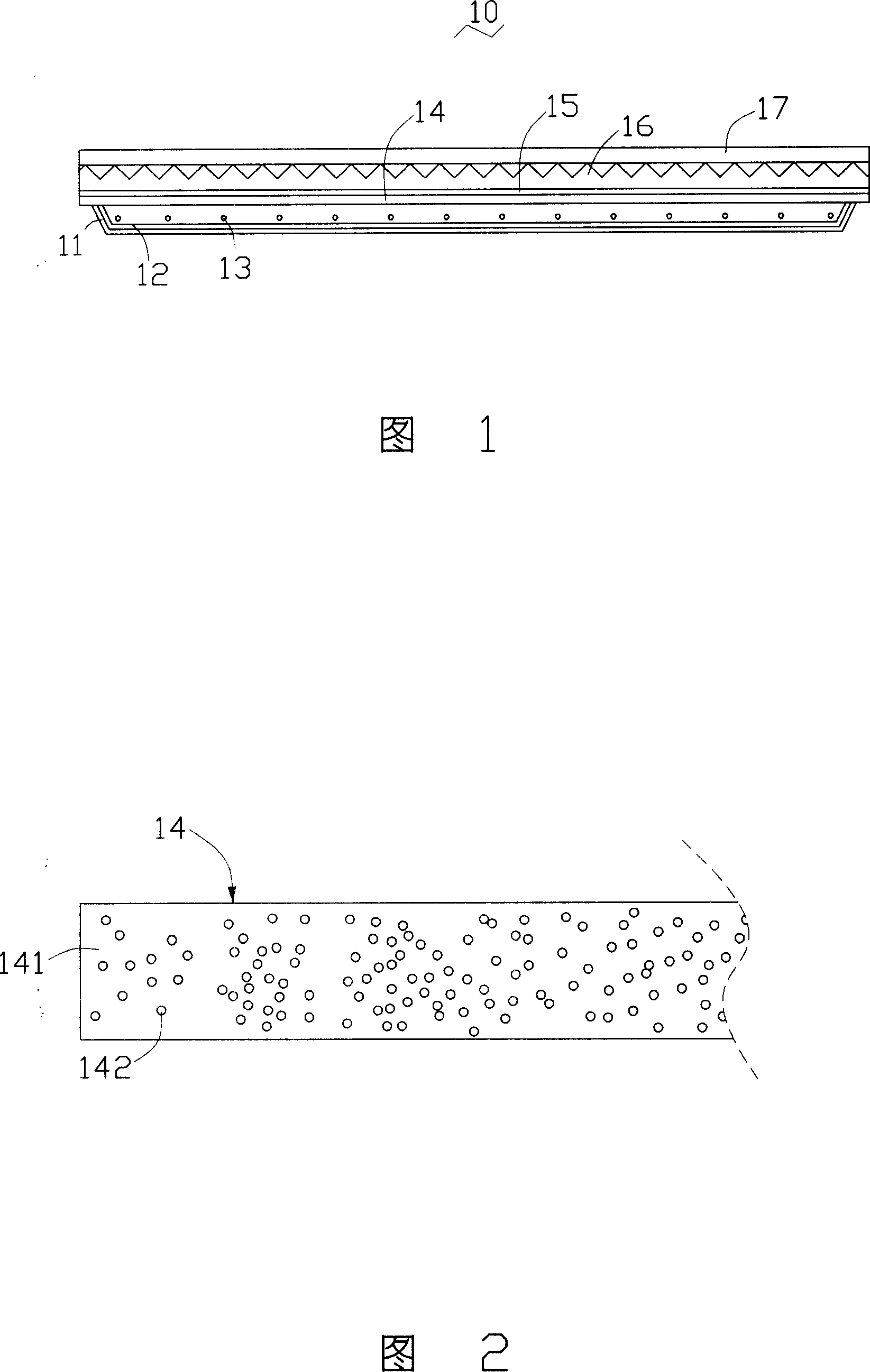

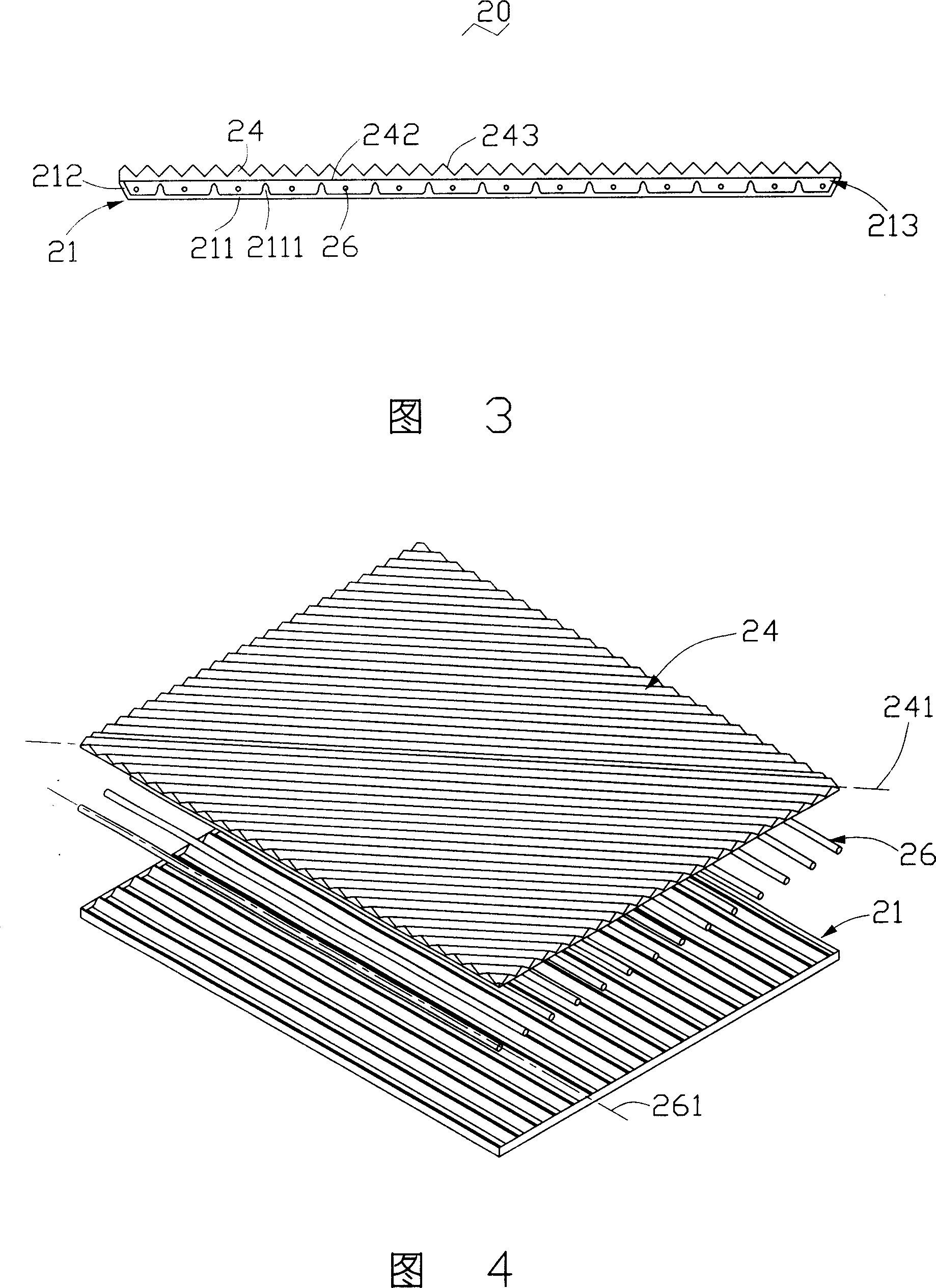

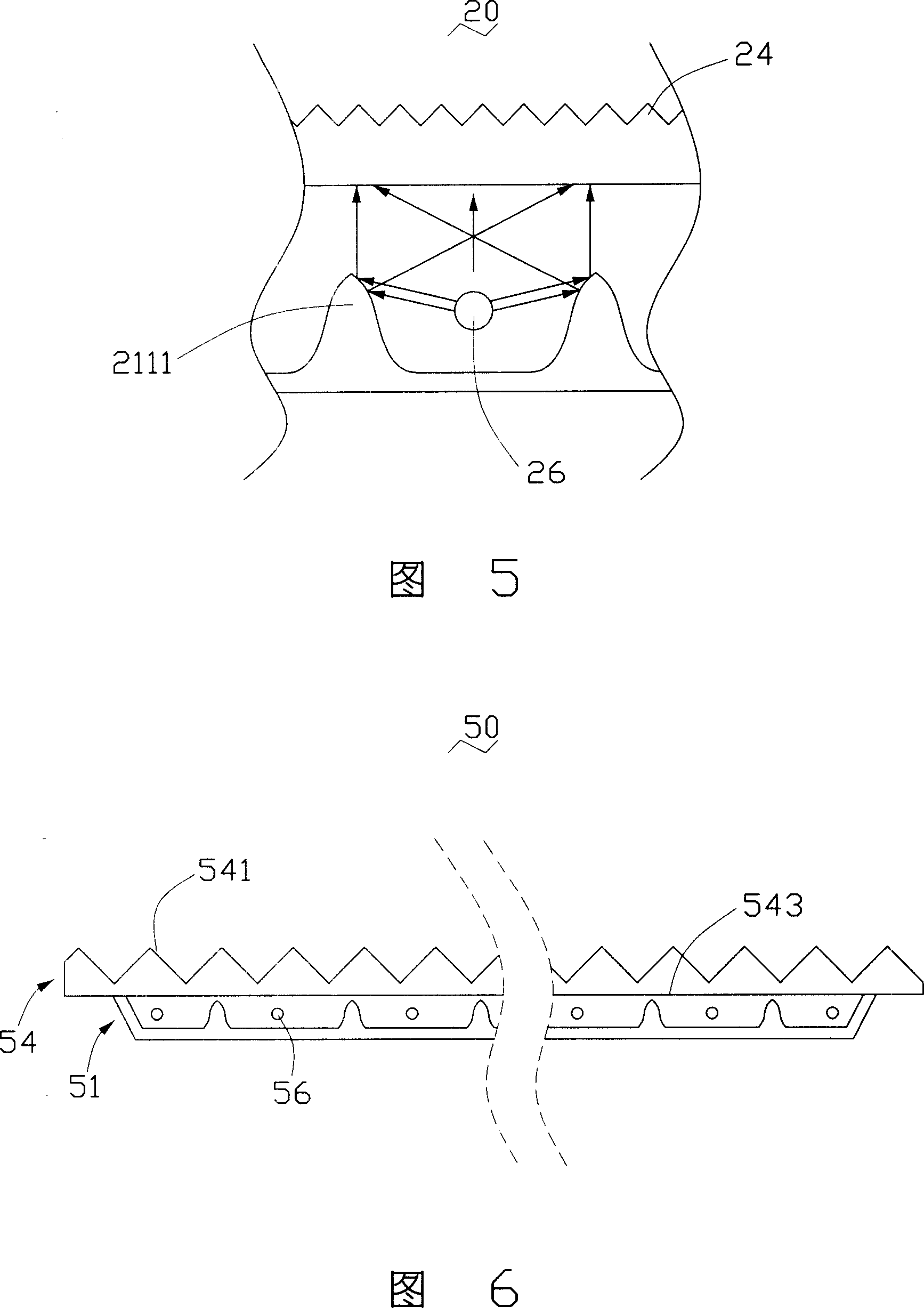

[0018] Referring to FIG. 3 , the first embodiment of the present invention provides a direct type backlight module 20 . The direct type backlight module 20 includes a casing 21 , a prism sheet 24 and a plurality of cold cathode ray tubes 26 .

[0019] The housing 21 has a bottom surface 211 and a plurality of side surfaces 212 connected at one end to the bottom surface 211. The other end of the plurality of side surfaces 212 forms an opening 213, and the housing bottom surface 211 is provided with a plurality of evenly spaced protrusions. The protrusion 2111 is a strip-shaped structure, and its two sides extending along the length direction of the protrusion 2111 are curved surfaces. The side surfaces of the two adjacent protrusions 2111 and the bottom surface 211 of the housing form a reflective curved surface.

[0020] The prism sheet 24 is located at the housing opening 213, and has a lower surface 242 adjacent to the housing bottom surface 211 and a prism surface 243 oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com