Positioning structure for tool head pivot-swing

A technology of positioning structure and head, applied in the direction of manufacturing tools, hand-held tools, wrenches, etc., to achieve the effect of increasing the force range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

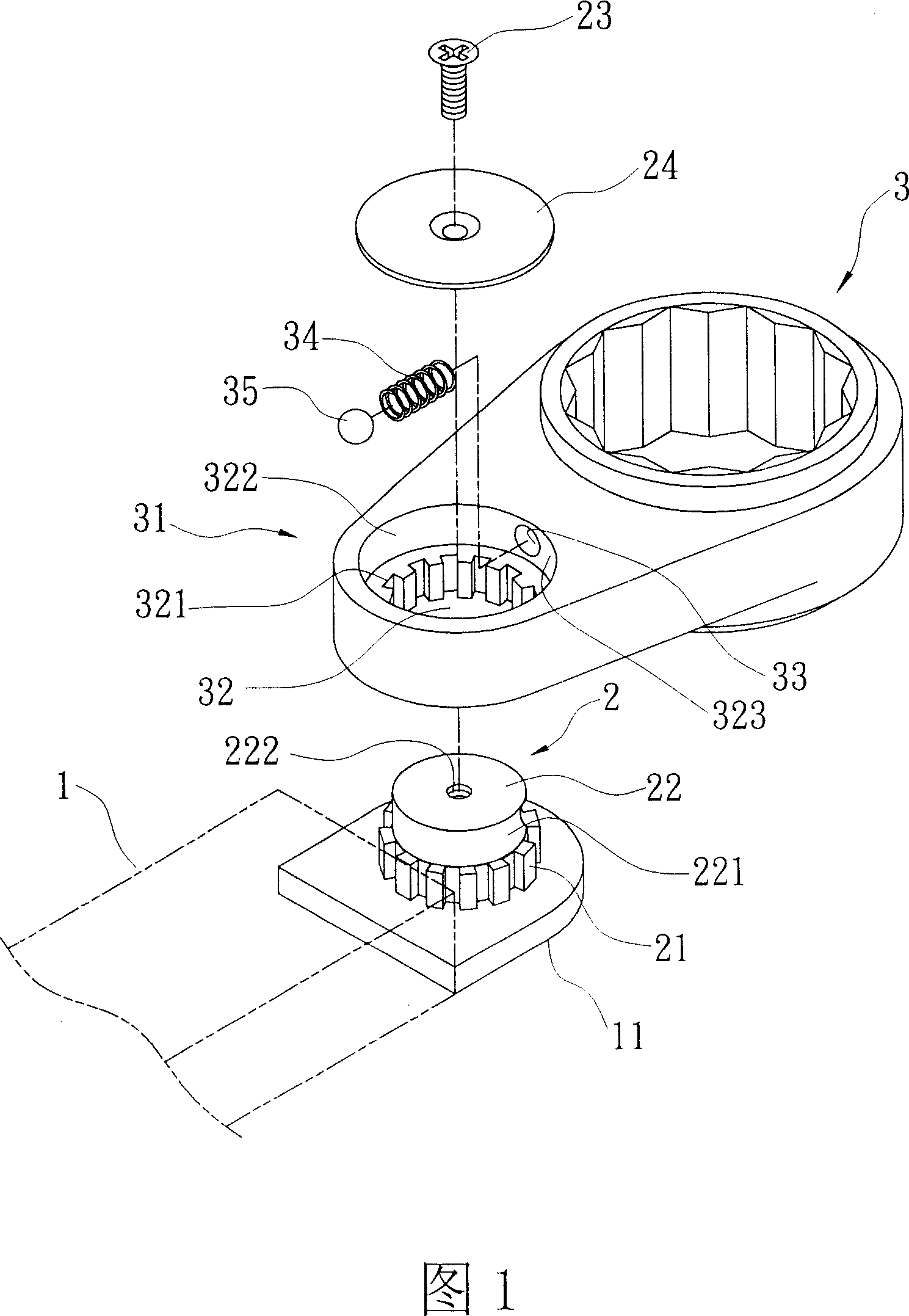

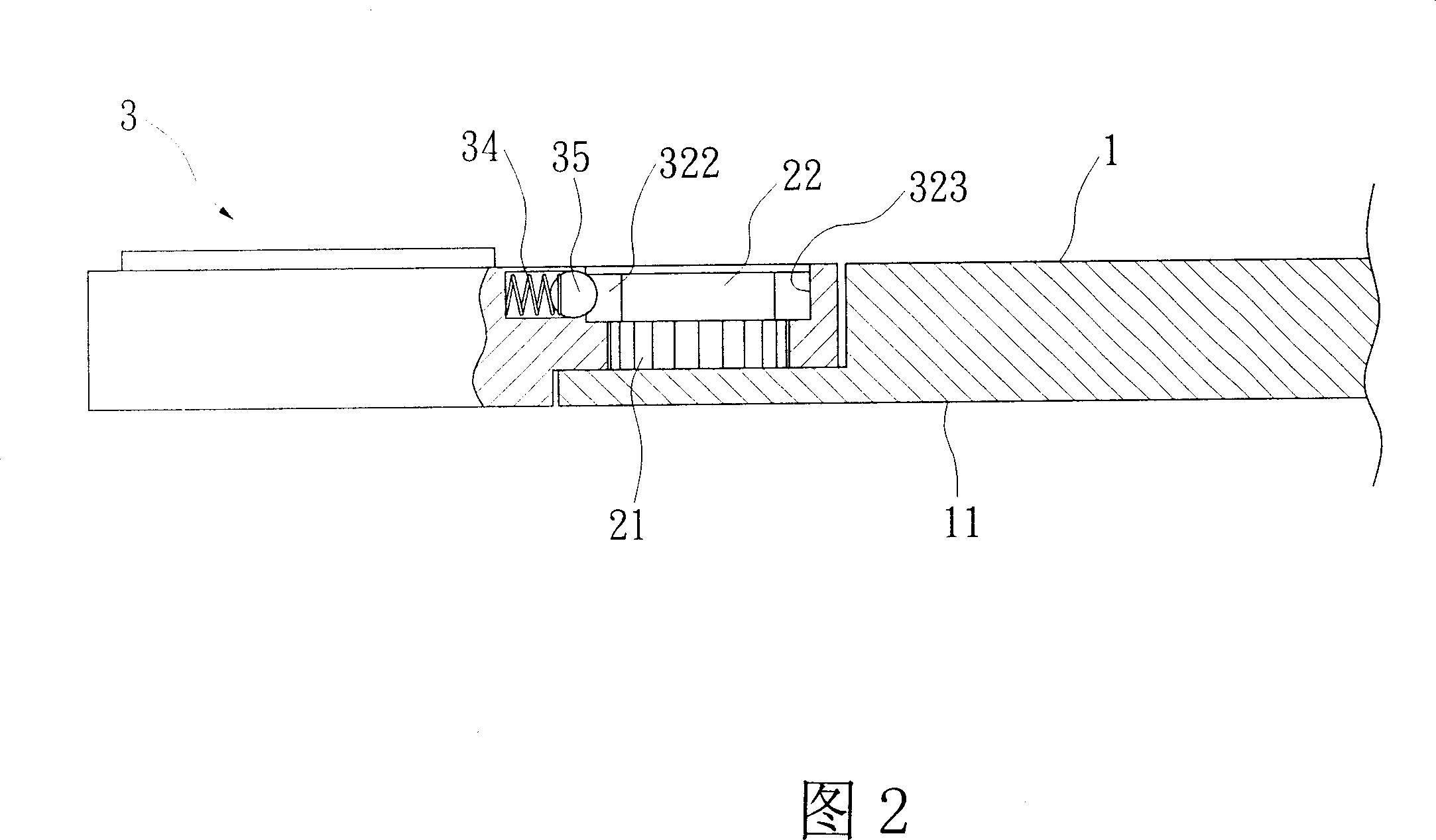

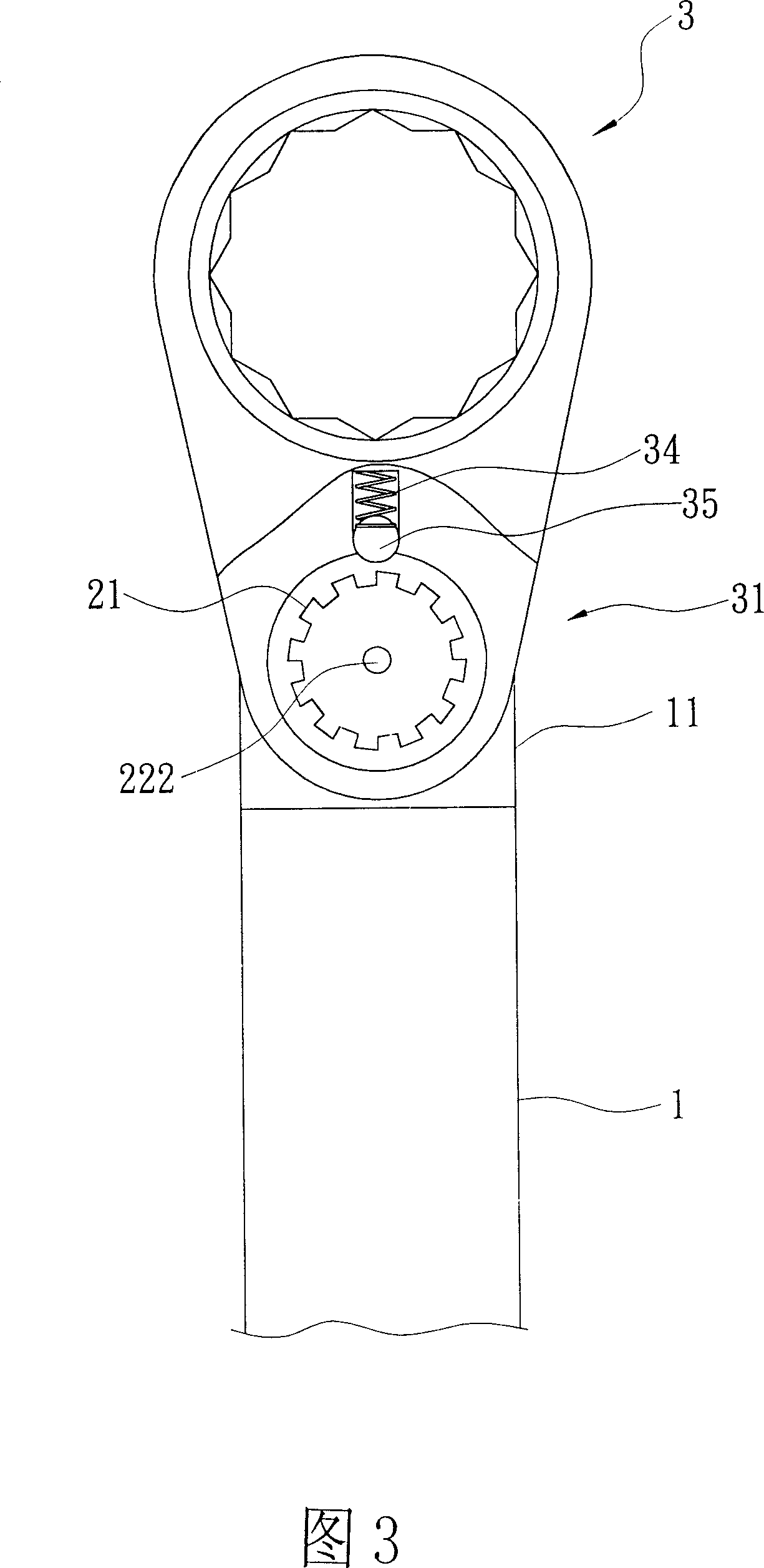

[0043] Please refer to FIG. 1 to FIG. 5 , which show the structure of the selected embodiment of the present invention.

[0044] The present invention is a tool head pivot positioning structure, comprising: a wrench body 1 , a first engaging unit 2 and a head body 3 .

[0045] One end of the wrench body 1 has a fixing unit 11 , and in this embodiment, the fixing unit 11 is lower than the height of the wrench body 1 .

[0046] The first engaging unit 2 is the fixing unit 11 fixed on the wrench body 1, and the first engaging unit 2 is composed of a first engaging unit 21 and a cylinder 22. In this embodiment, the first The first engaging unit 21 of the engaging portion 2 is a cylinder with an external toothed segment.

[0047] One side of the head body 3 has a second engaging unit 31 which is engaged with the above-mentioned first engaging unit 2 , and the two can be combined and disengaged from each other. The second engaging unit 31 has an opening 32 , which passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com