Building decoration material composite aluminum-plastic plate and manufacturing and processing method thereof

A building decoration material and composite aluminum technology, which is applied in the field of composite aluminum composite panel processing, can solve the problems of large deformation, easy cracks or wrinkles, and large impact on aluminum composite panels, so as to improve the safety of use and ensure that no deviation occurs. The effect of moving and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

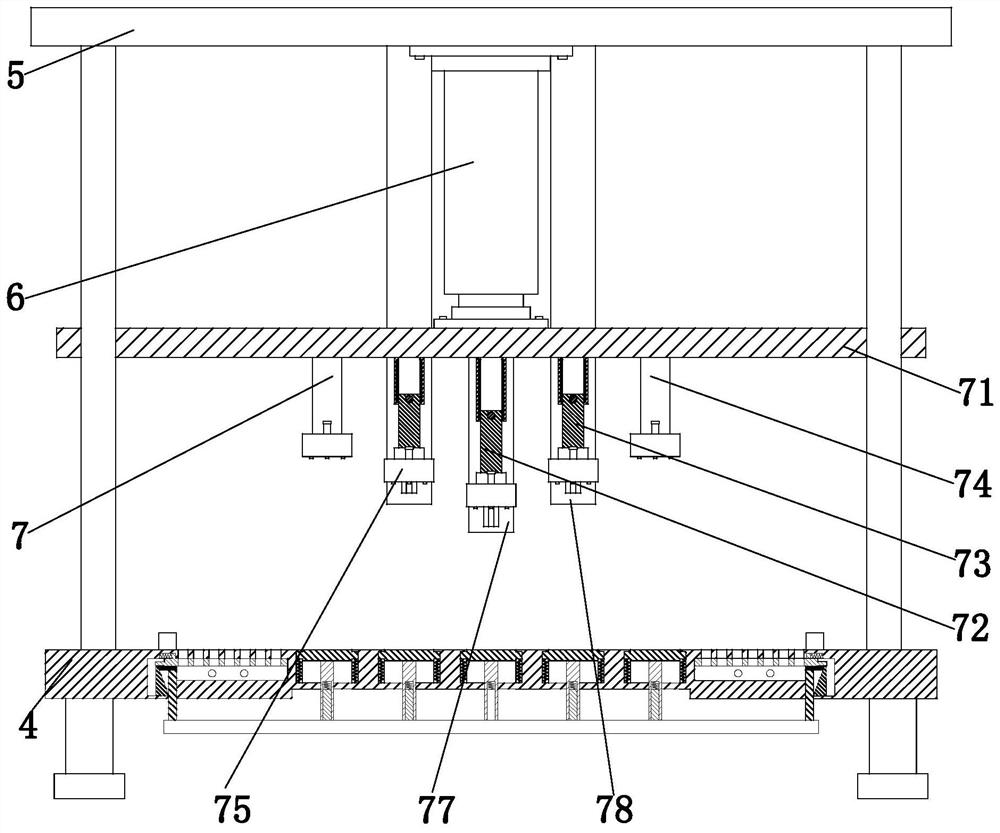

[0036] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

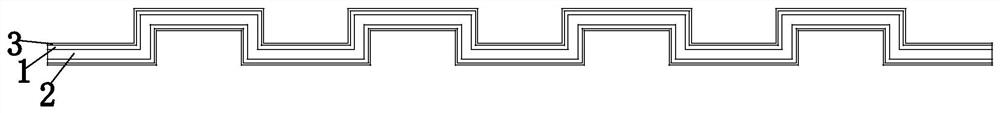

[0037] A composite aluminum-plastic board for building decoration materials, including an aluminum board 1, a PE core material 2 and a protective film 3, the number of the aluminum boards 1 is two, the two aluminum boards 1 are arranged symmetrically up and down, and the two aluminum boards 1 arranged symmetrically up and down are glued together There is a PE core material 2, the outer side of the aluminum plate 1 is covered with a protective film 3, the aluminum plate 1, the PE core material 2 and the protective film 3 are all concave and convex structures; where:

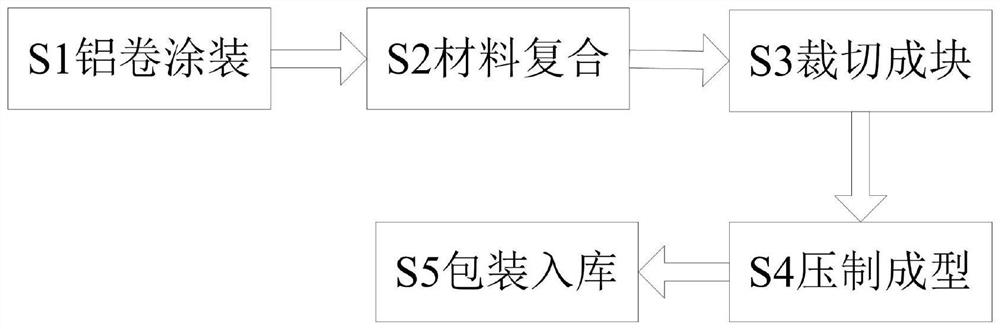

[0038] In the manufacturing and processing process of the above-mentioned building decoration material composite aluminum-plastic panel, it is necessary to use special pressing and form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com