Taper ring transmission with surface optimization of contact region

A transmission and cone ring technology, applied in friction transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as reduced efficiency, increased transmission wear, and difficult design of cone ring transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

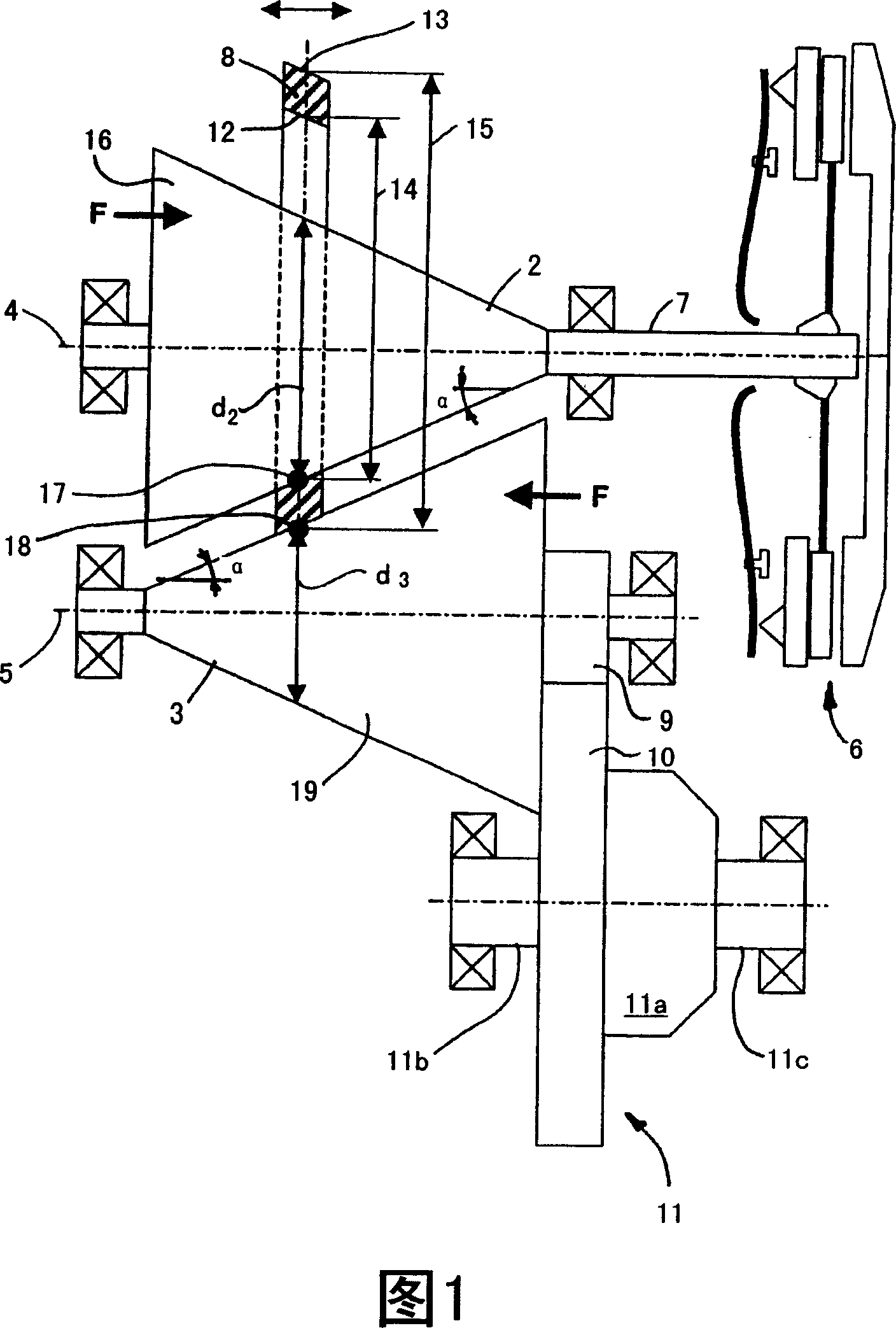

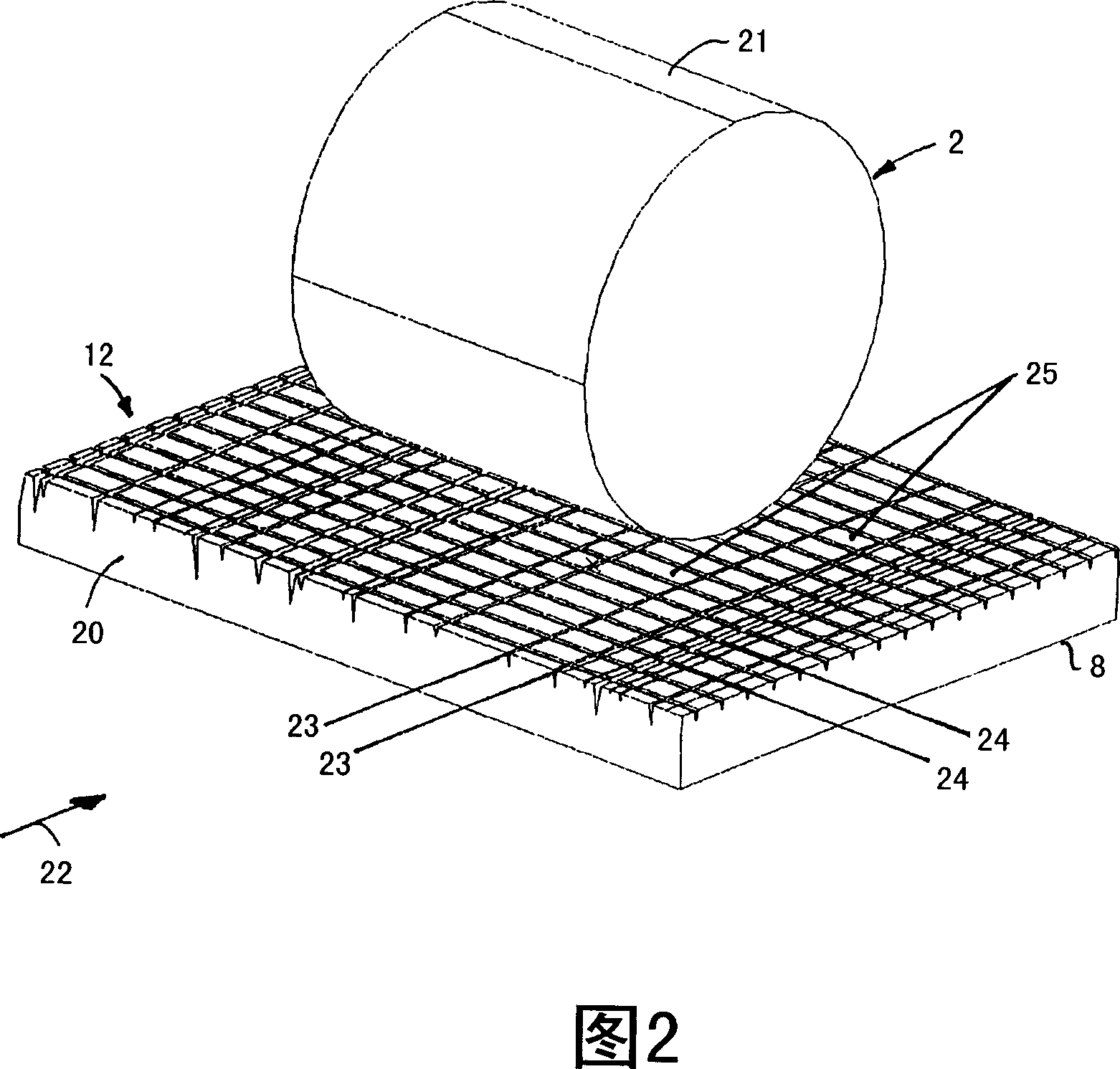

[0024] FIG. 1 shows a conical ring transmission designated as a whole by 1 . The bevel ring transmission 1 has a first conical friction wheel 2 and a second conical friction wheel 3 . The conical friction wheels 2 , 3 are arranged opposite to each other, wherein their axes of rotation run parallel and are spaced apart from each other. The axes of rotation of the conical friction wheels 2 , 3 are indicated by dashed lines 4 , 5 .

[0025] In addition to the cone ring transmission 1 , FIG. 1 also shows a clutch 6 of a motor vehicle, which is not further shown here. The clutch 6 is non-rotatably connected to the first conical friction wheel 2 via a shaft 7 . In the closed state, the clutch 6 transmits the torque via the shaft to the first conical friction wheel 2 . In order to transmit the torque from the first conical friction wheel 2 to the second conical friction wheel 3, a friction ring 8 is provided, which interacts with the two conical friction wheels 2, 3 and surrounds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com