Umbrella which enables separation and discard

An easy, umbrella shaft technology, applied in the field of automatic opening umbrellas, can solve the problems of time-consuming assembly, difficulty in separating metal parts and non-metal parts, and difficulty in realizing the recycling of precious resources, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

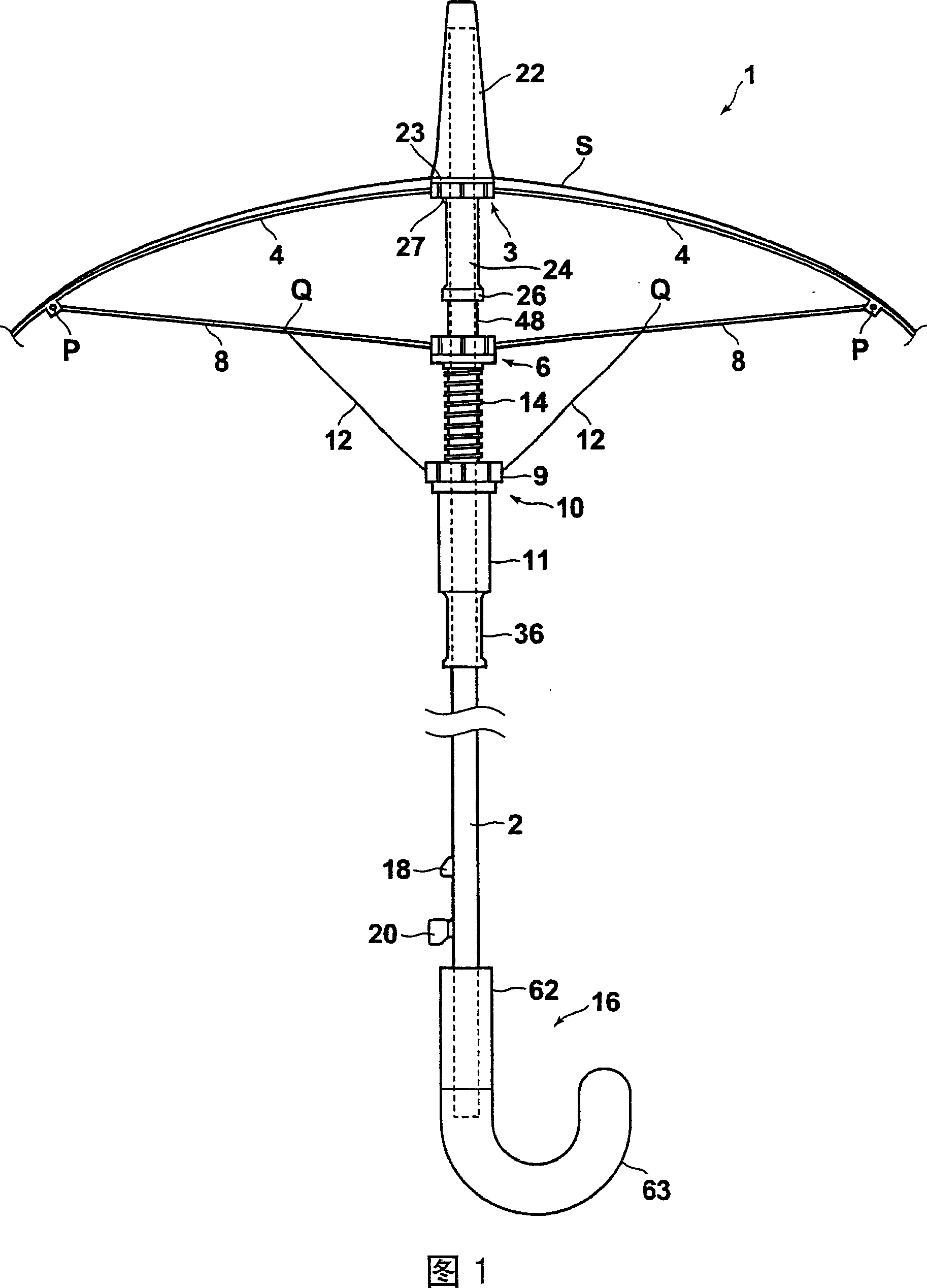

[0055] Fig. 1 is a schematic diagram showing the overall structure in an open state of the first embodiment of the separably discardable umbrella of the present invention with a part omitted.

[0056] In FIG. 1 , an umbrella 1 as a button operated umbrella includes: a metal pillar (shaft) 2; a resin upper umbrella shaft (crown hub) fitted and fixed at the front end of the pillar 2 3; metal main ribs 4 with root portions pivoted on the upper umbrella shaft 3; cloth or resin umbrellas laid along these main ribs 4 cloth (sheet) S; the resin upper sliding hub 6 which is slidably fitted and installed on the pillar 2 is pivotally mounted on the upper sliding hub 6, and the front end is pivoted. ) a plurality of metal supporting ribs (supporting ribs) 8 at a point P in the middle of the main rib 4; and a resin lower umbrella shaft slidably fitted and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com