Perpendicular magnetic record medium and magnetic storage system

A technology of perpendicular magnetic recording and magnetic recording, which is applied in the direction of recording information storage, magnetic recording, recording head casing/shield cover, etc., which can solve the problem of reducing the magnetic anisotropy energy of magnetic crystal grains, failing to obtain low-noise characteristics, and failing to obtain issues of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

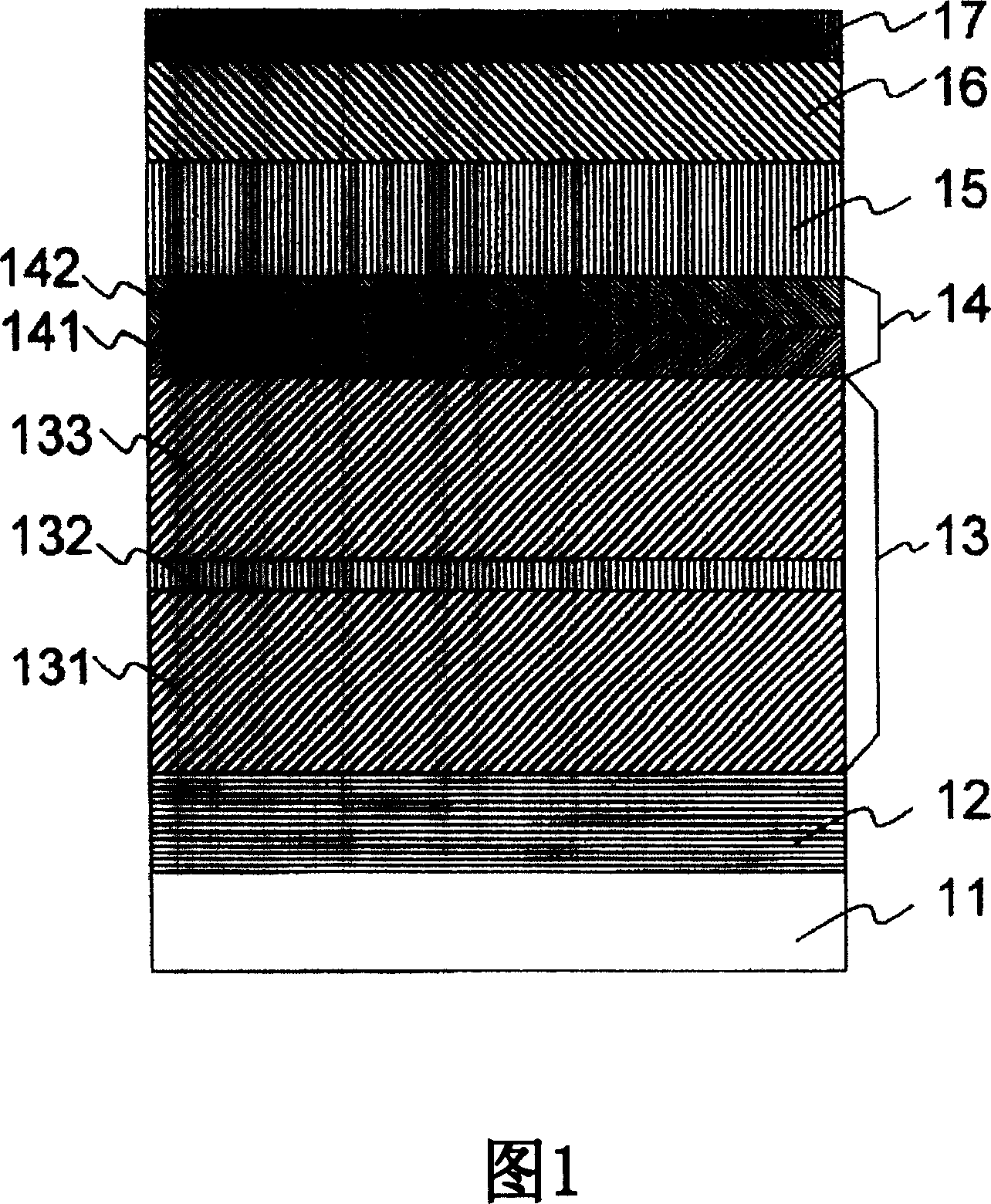

[0050] FIG. 1 shows the layer structure of the perpendicular magnetic recording medium of this embodiment. A glass magnetic disk substrate (2.5-inch type) having a thickness of 0.63 mm and a diameter of 6.5 mm formed on its surface with concentric circular grooves was used as the substrate 11 . On the substrate 11 , an adhesion layer 12 , a soft underlayer 13 , a first seed layer 141 , a second seed layer 142 , an intermediate layer 15 , a perpendicular recording layer 16 and an overcoat layer 17 are sequentially formed by sputtering. Table 1 summarizes the target composition, Ar gas pressure, and film thickness used in this example.

[0051] Table 1

[0052] target ingredient

(at.%)

Ar air pressure (Pa)

Rate(nm / s)

Thickness (nm)

Adhesive layer 12

Ni 63 Ta 37

1

5

10

soft bottom

Layer 13

First soft layer 131

co 92 Ta 3 Zr 5

0.5

12.5

50...

no. 2 example

[0068] A dielectric having the same layer structure as Dielectric 1-1 of the first embodiment but having a different seed layer was manufactured, and its dielectric S / N and corrosion resistance were evaluated by the same technique as used in the first embodiment. Except for the seed layer, the composition, film thickness, and film formation process of each layer were the same as those of Medium 1-1. Here, each material used for the first seed layer is an amorphous alloy, and each material used for the second seed layer is a crystalline alloy having a face centered cubic (fcc) structure. The film thicknesses were set to 2 nm and 5 nm, respectively.

[0069] Table 4

[0070] sample

[0071] The media 4-1 to 4-8 are media whose first seed layer was fixed to CrTi and whose material of the second seed layer was changed. In addition, media 4-9 to 4-15 are media whose second seed layer is fixed to NiW and whose first seed layer material is changed. As shown in Table 4, e...

no. 3 example

[0073] Several media having the same layer structure as the medium 1-1 of the first embodiment but having recording layers different from those media were manufactured, and their media S / N were evaluated using the same technique as used in the first embodiment and corrosion resistance. Except for the recording layer, the composition, film thickness, and film forming process of each layer were the same as those of Medium 1-1. The medium 5-1 is composed of a recording layer having a granular structure composed of CoCrPt to which Ta oxide is added. The recording layers of the medium 5-2 and the medium 5-3 are composed of a multilayer of Co and Pd and a multilayer of Co and Pt, respectively.

[0074] As shown in Table 5, the corrosion resistance of each was excellent and was in rank A. In terms of medium S / N, medium 5-1 is the best. Therefore, it was found that even if a Co / Pd or Co / Pt multilayer is used for the recording layer, an excellent medium S / N can be obtained with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com