Method for packaging a spectacle lens

a technology of spectacle lens and packaging method, which is applied in the direction of instruments, packaged goods, shock-sensitive objects, etc., can solve the problems of high risk of degrading the surface state of said convex face, and achieve the effect of low cost, no complicated manipulation requiring precision, and simple and rapid operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

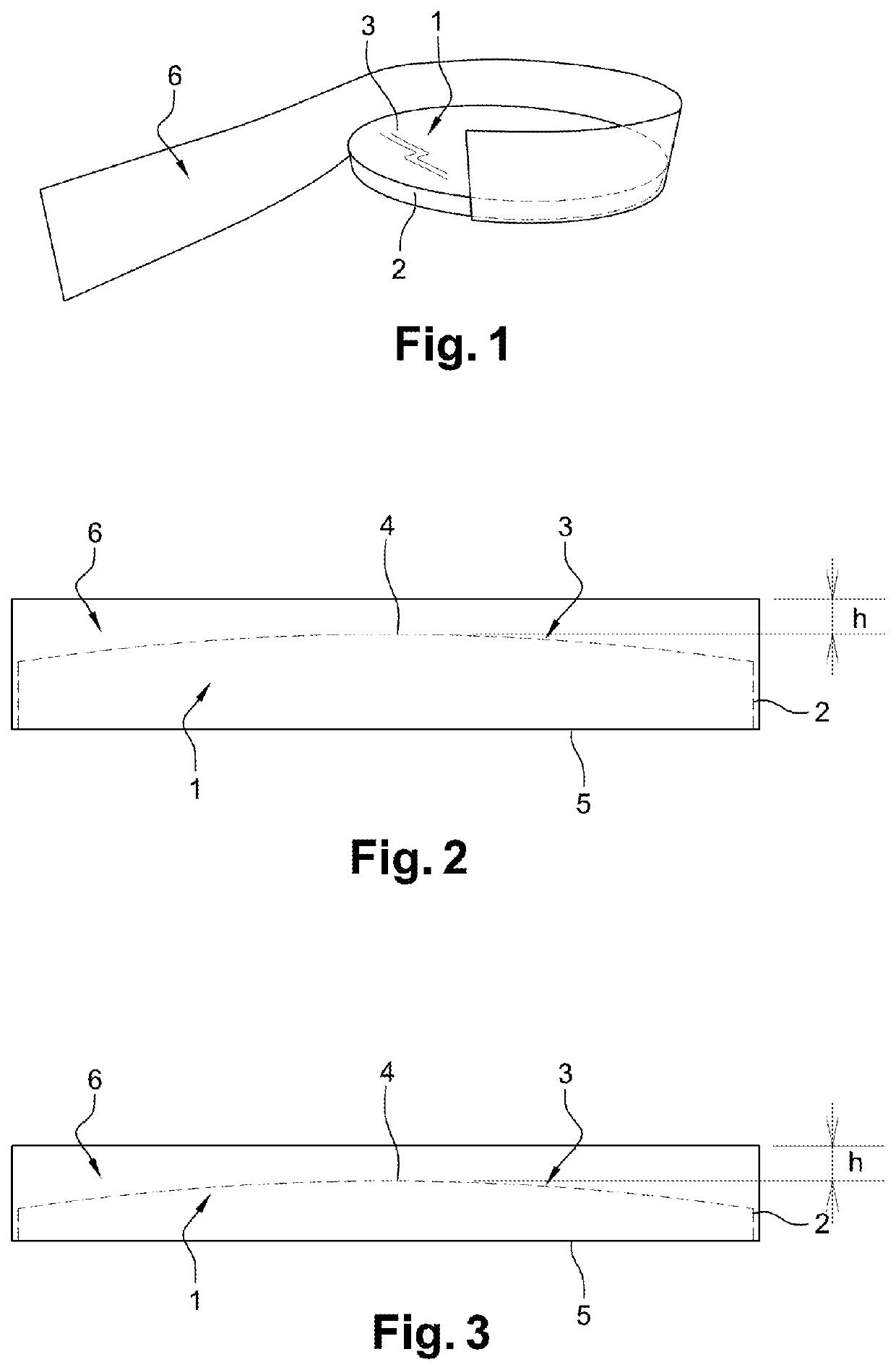

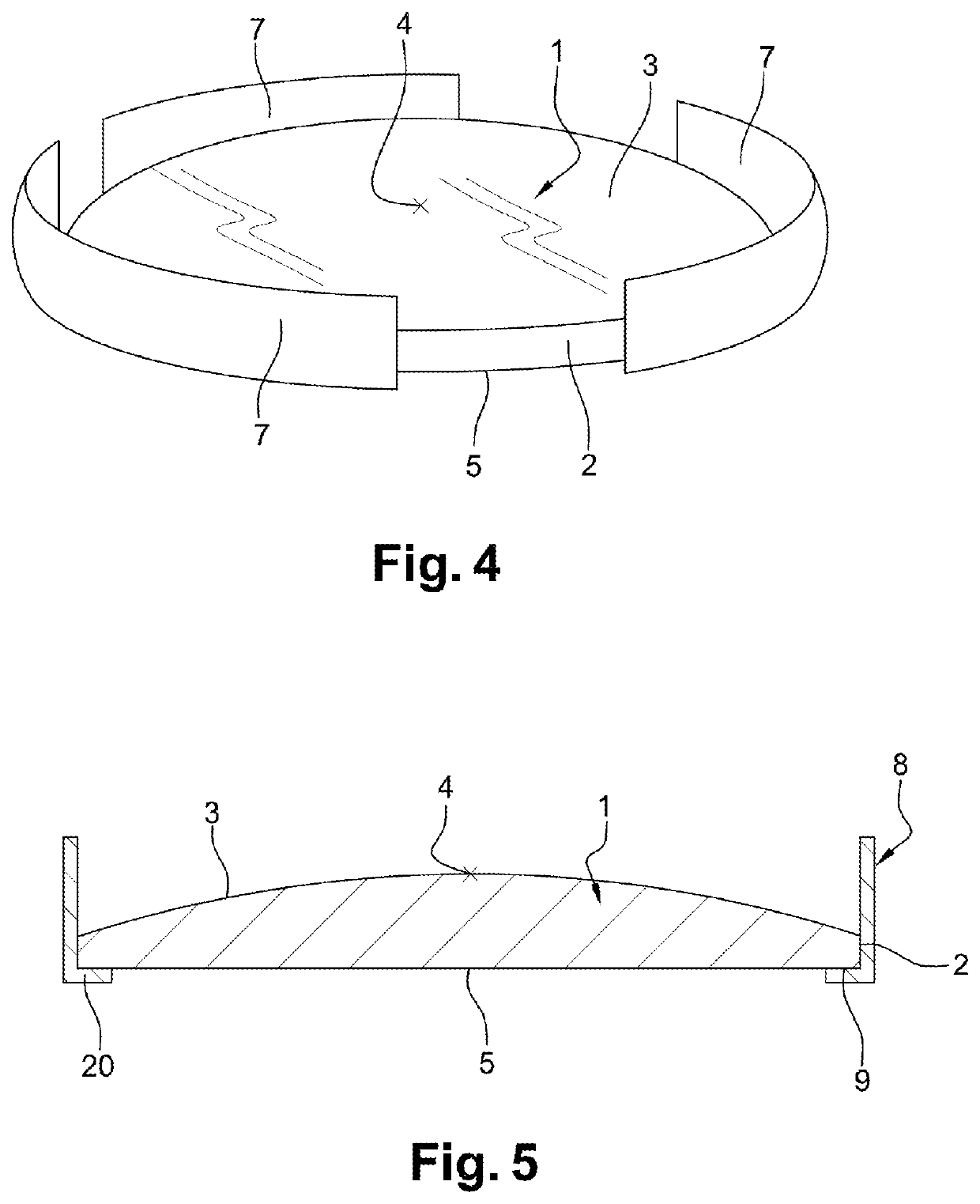

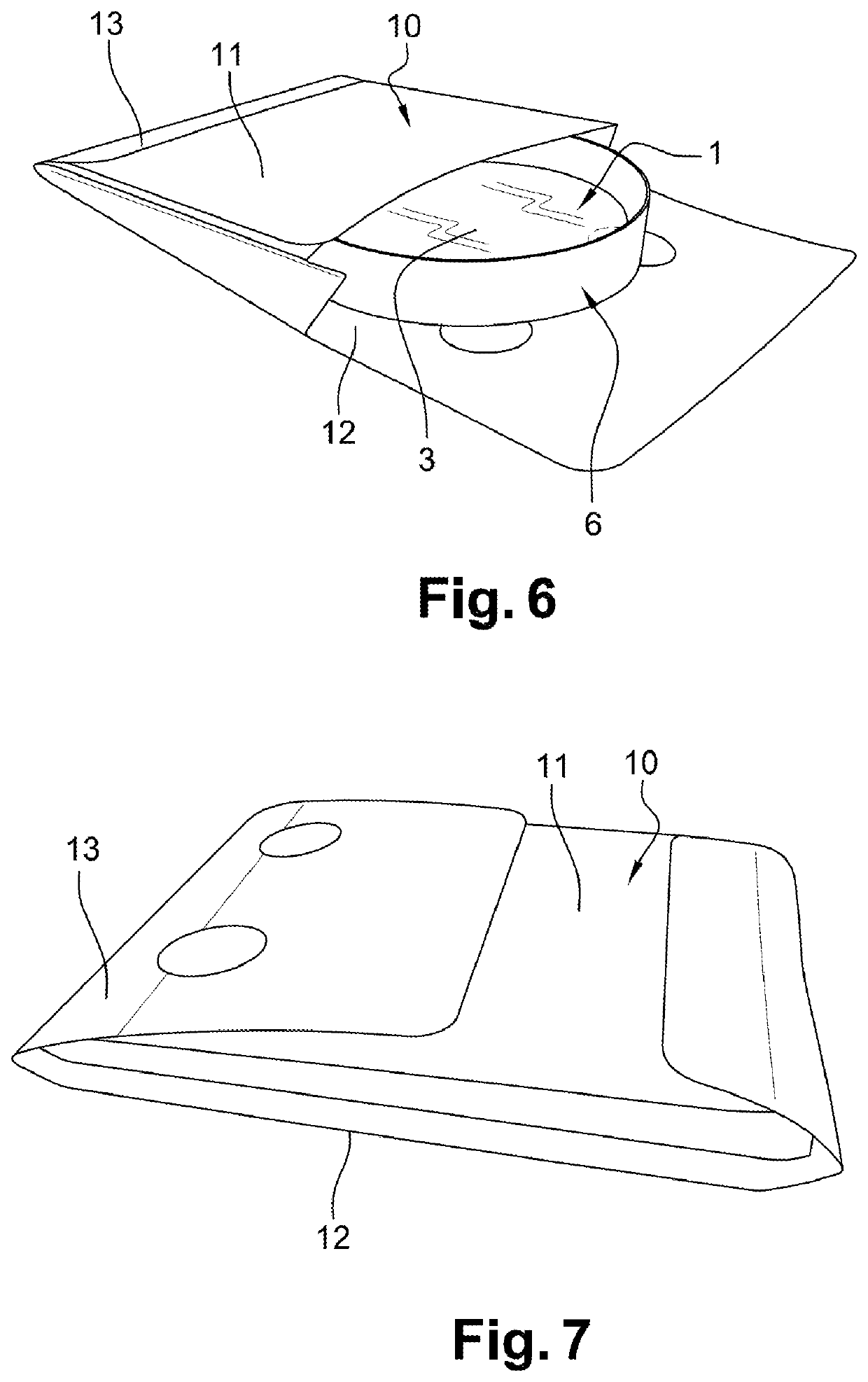

[0069]In the following detailed description, it is assumed that a protective strip is fixed to an optical lens by gluing it on. Actually, a fixing technique of this kind is particularly suited to a packaging method according to the invention.

[0070]It is moreover understood that the term “lens” employed in the present description must be understood according to the following definition: the lens referred to here corresponds to an optical article of the ophthalmic lens type, an ocular visor, and optical viewing systems. In particular an ophthalmic lens is a lens that is designed to fit a spectacle frame in order to protect the eye and / or to correct the vision and may be a non-correcting ophthalmic lens (also termed a plano or an afocal lens) or corrective. A corrective lens may be a unifocal, bifocal, trifocal or progressive lens. The ophthalmic lens may be a finished lens or a semi-finished lens, intended to be reworked by machining one of its principal faces in order to impart a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com