Quick change structure for multi-functional saws and quick change method

a multi-functional, quick change technology, applied in the direction of metal sawing tools, metal sawing apparatus, metal-working equipment, etc., can solve the problems of complex fastening and dismantling operations, potential safety hazards, failure of fastening, etc., to improve the operation feeling of products, quick change of saw blades, and expansion of the application scope of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to help people further understand the contents of the present invention, the present invention is described in detail in conjunction with the attached drawings and embodiments. The following embodiments apply to the present invention, but cannot be regarded as limiting the scope of the present invention.

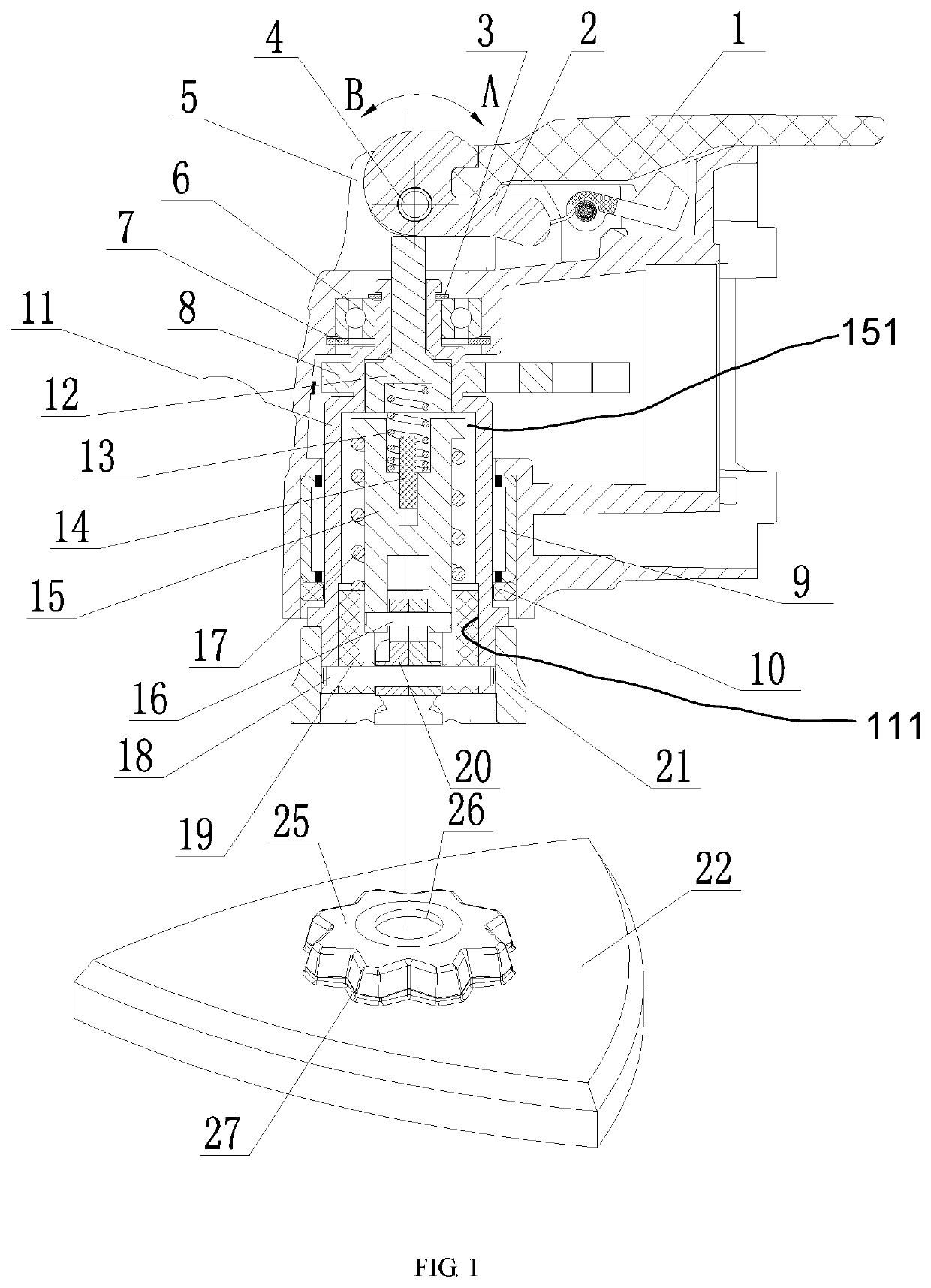

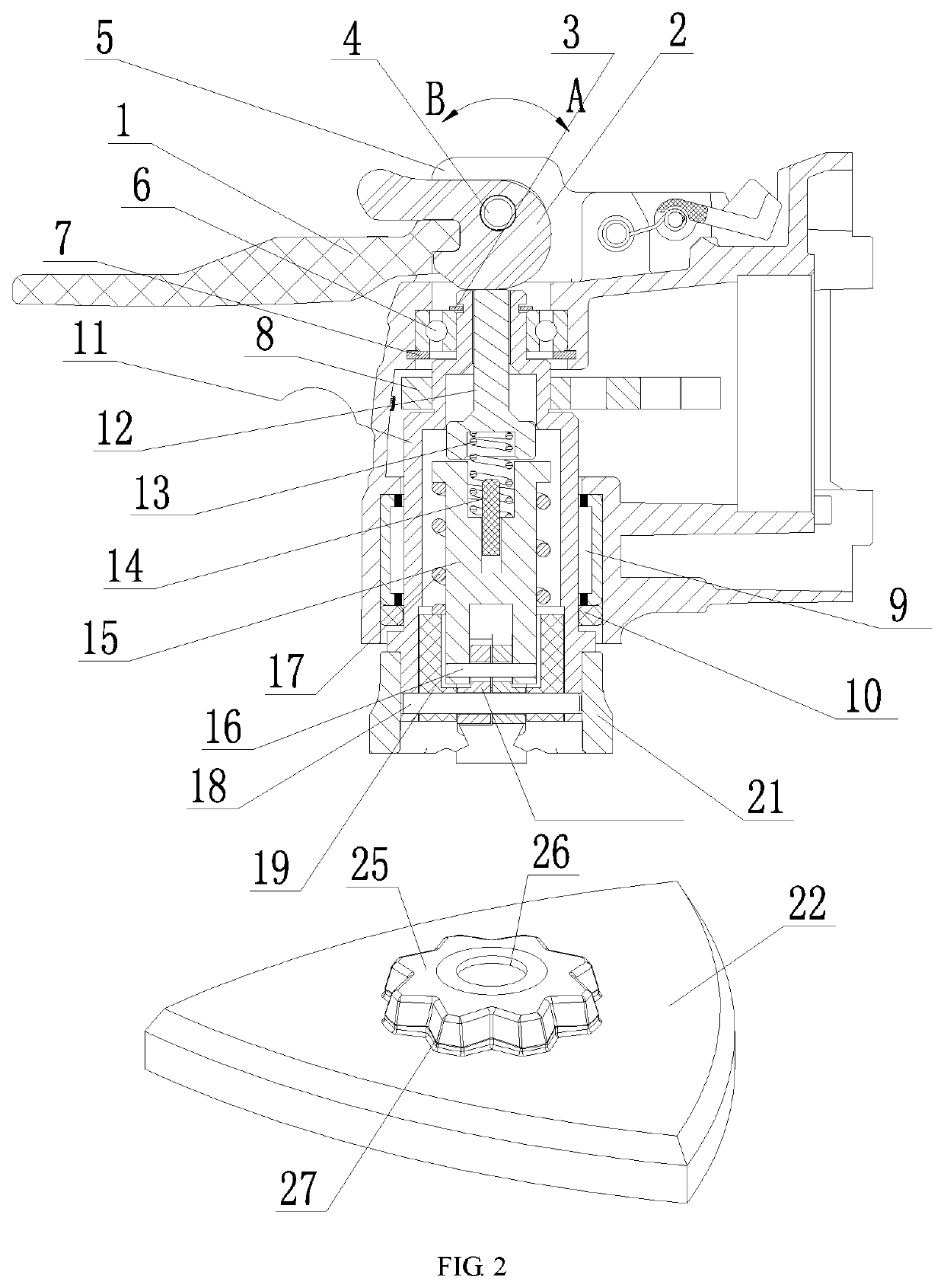

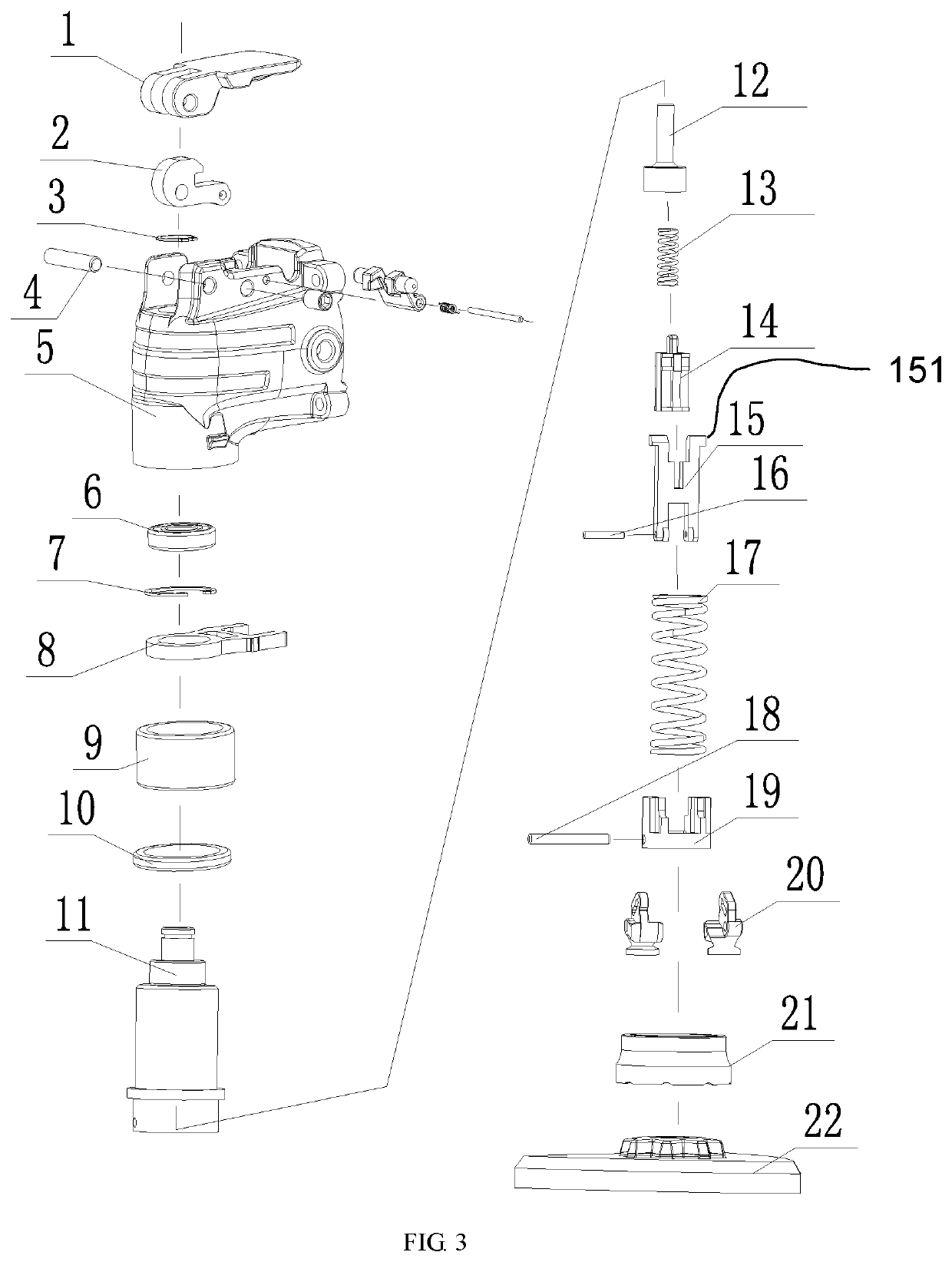

[0038]As shown in FIG. 1, in this embodiment, a quick change structure for multi-functional saws includes a quick change handle 1, an eccentric block 2, a snap spring 3, a first cylindrical pin 4, a head housing 5, a deep groove ball bearing 6, a snap spring 7, a shift fork 8, a needle bearing 9, a sealing ring 10, an output shaft 11, a movable rod 12, a small cylindrical compression spring 13, a plastic support block 14, a movable bracket 15, a second cylindrical pin 16, a cylindrical compression spring 17, a third cylindrical pin 18, a plastic fixed seat 19, a locking pin 20, a positioning ring 21 and a saw blade 22. The top of the head housing 5 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com