Set of golf clubs

a golf club and set technology, applied in the field of golf clubs, can solve the problems of increasing the weight of the bottom part of the head, stiffening the central zone, and reducing the "sweet spot" of the head, and achieve the effect of reducing the weight of the upper par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

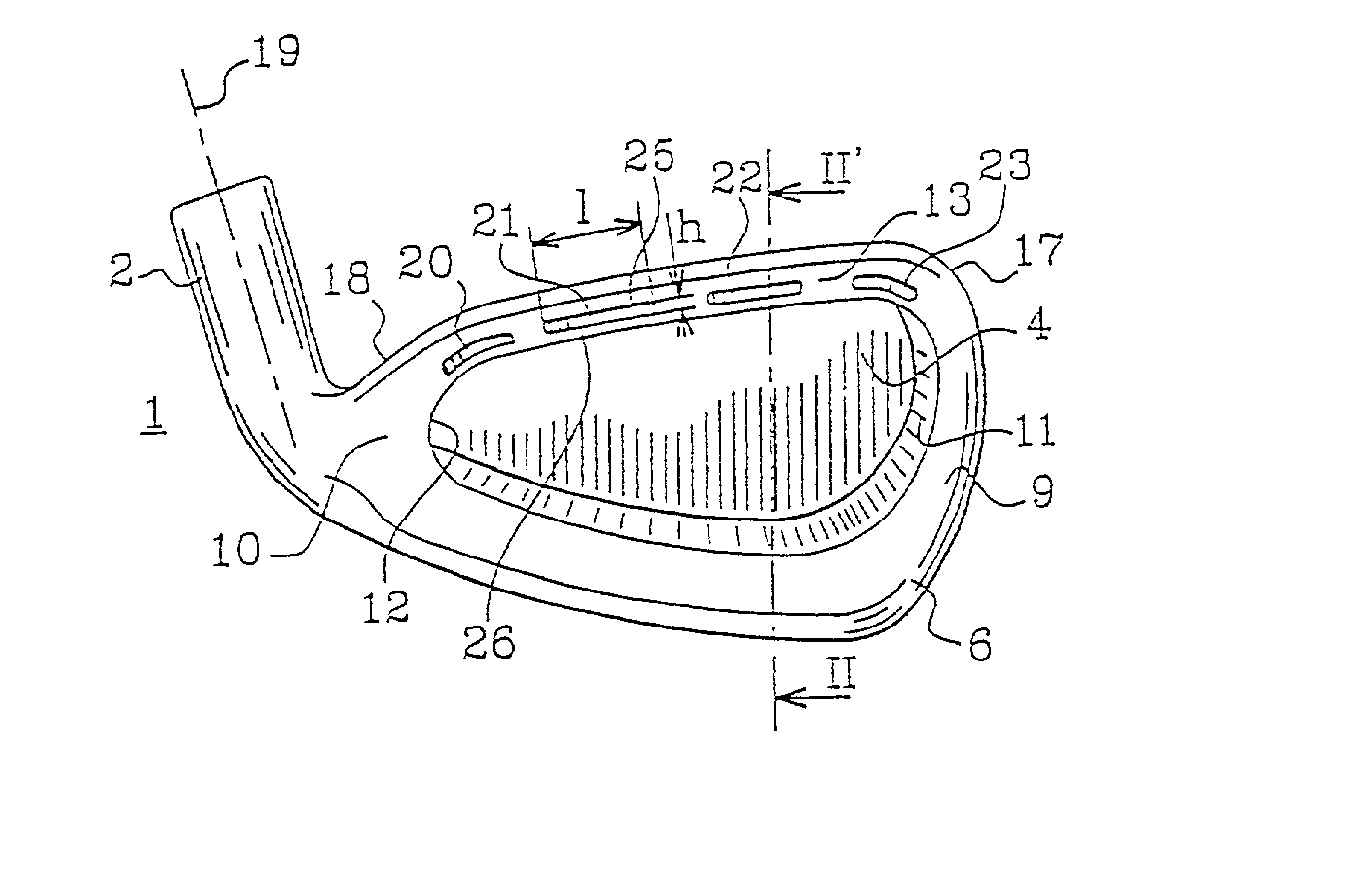

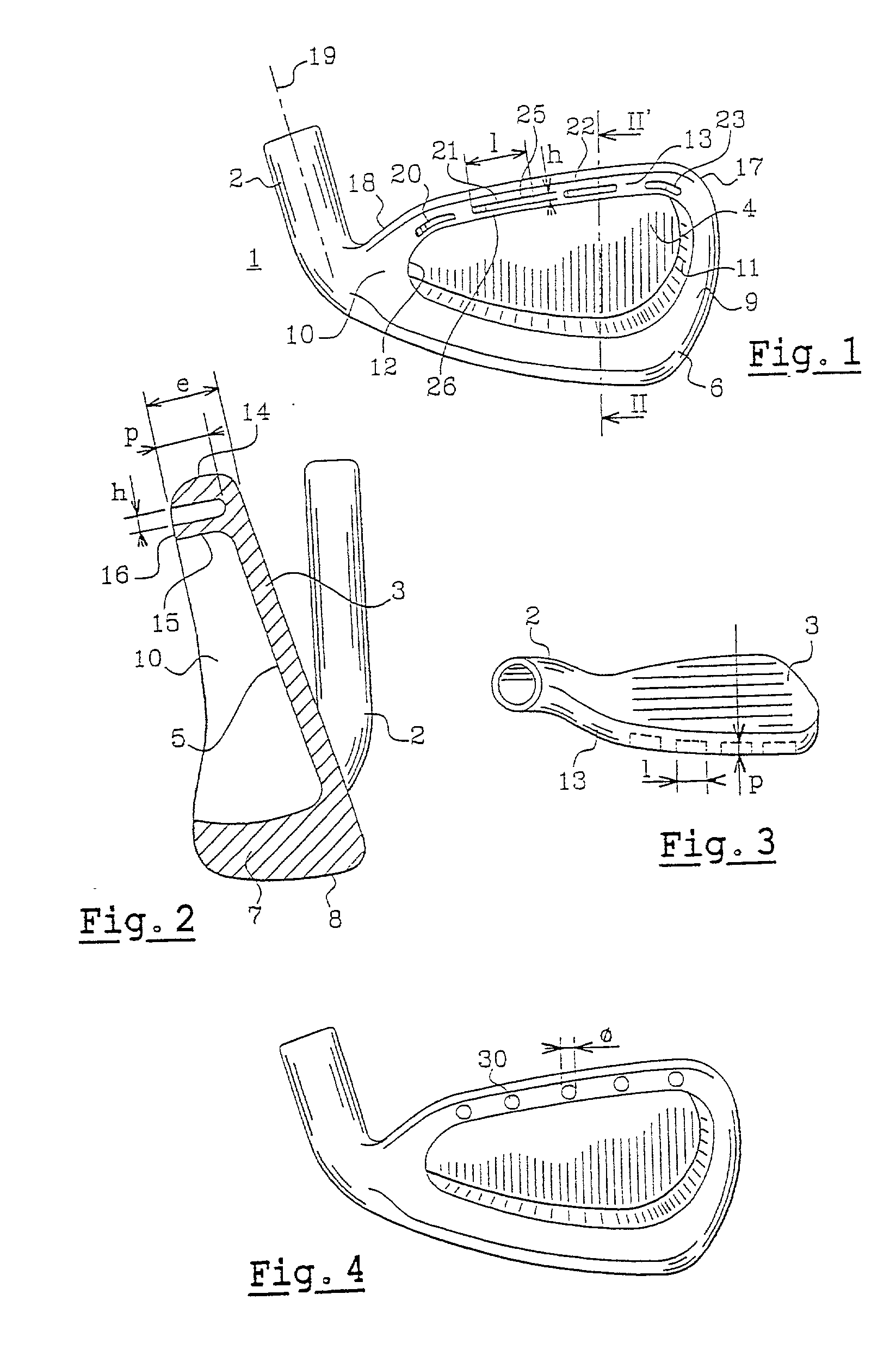

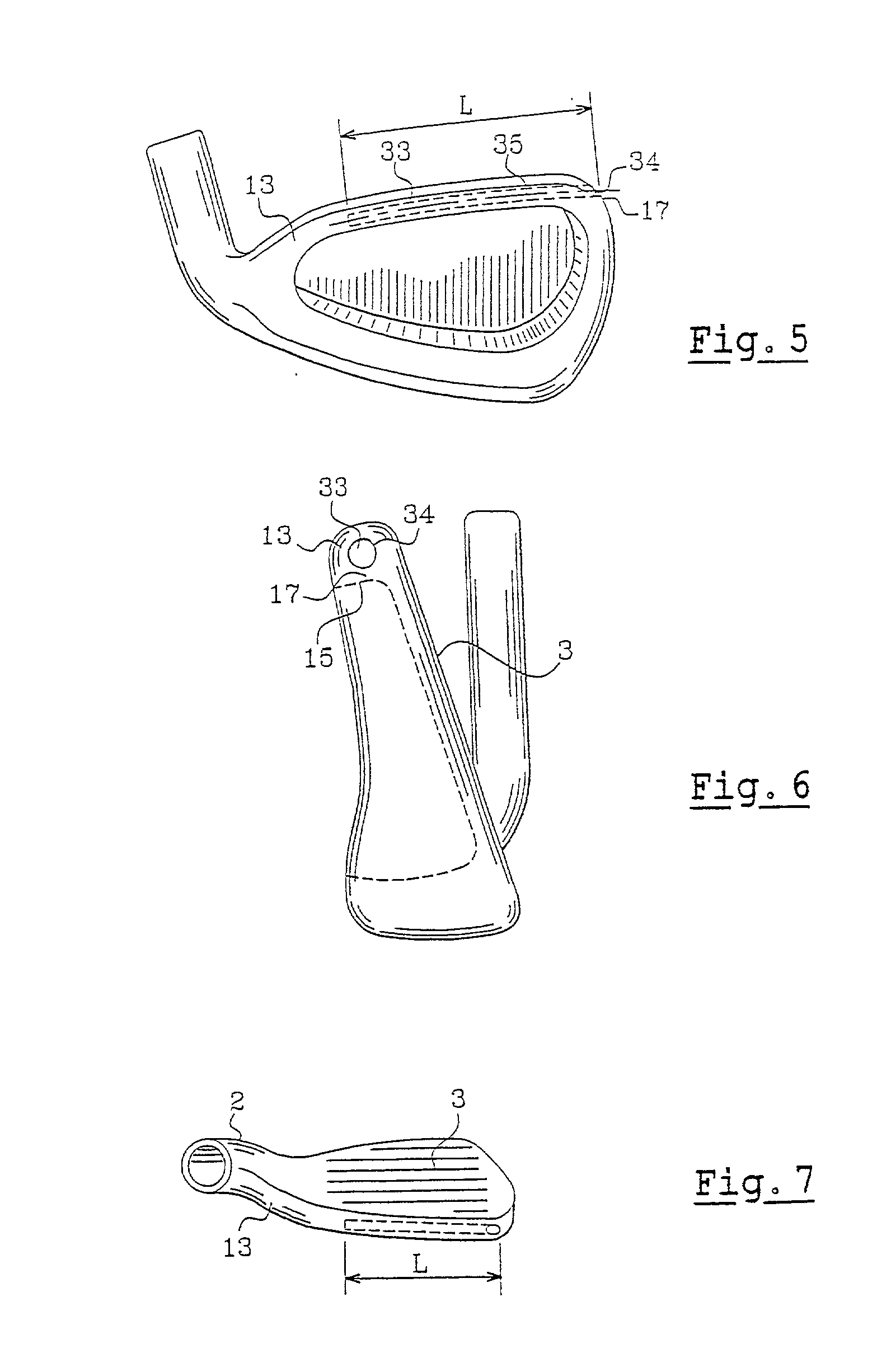

[0043] As already stated, the invention relates to a head of a golf club of the "iron" type. In general, and as illustrated in FIGS. 1 and 2, such a head (1) comprises a hosel (2) intended to be connected to the shaft, and a striking face (3) which makes impact with the ball.

[0044] In its rear part, the head (1) comprises a cavity (4), the bottom (5) of which is behind the striking face (3). This cavity (4) is delimited laterally by a perimeter (6) consisting of various walls.

[0045] More specifically, this perimeter (6) comprises a lower wall (7) forming the sole of the head and the lower face (8) of which faces the ground at the moment of impact. The perimeter (6) also comprises two lateral walls (9, 10), the inner faces (11, 12) of which face toward the cavity (4). The perimeter (6) also comprises an upper wall (13). This upper wall (13) comprises several faces, namely:

[0046] an upper face (14) situated in the field of view of the golfer when he strikes the ball,

[0047] a lower fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com